Production process of road asphalt

A technology of road asphalt and production process, applied in building components, building insulation materials, buildings, etc., can solve problems such as poor functionality, inability to adapt to high and low temperature environments, and achieve the effects of easy operation, good use performance, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

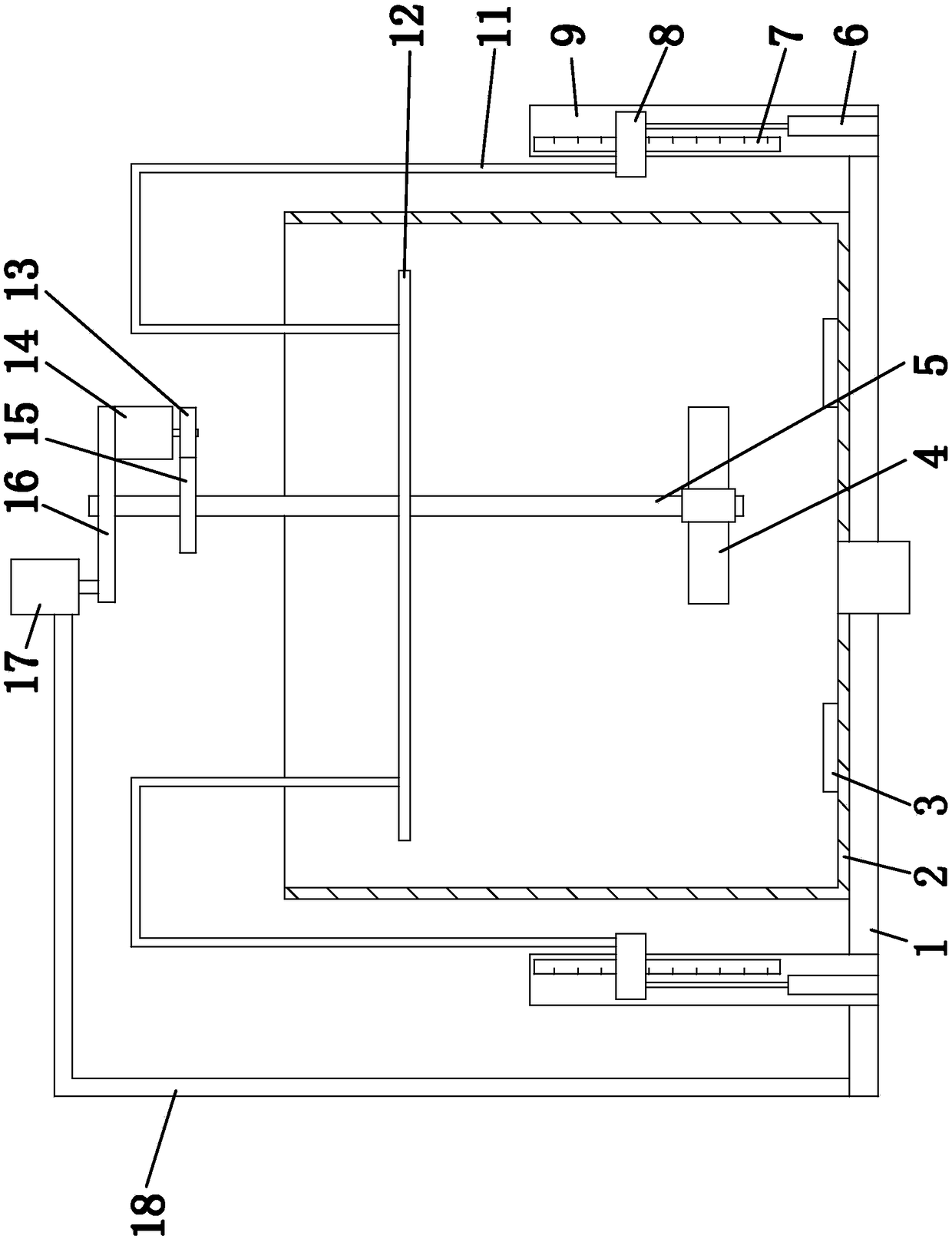

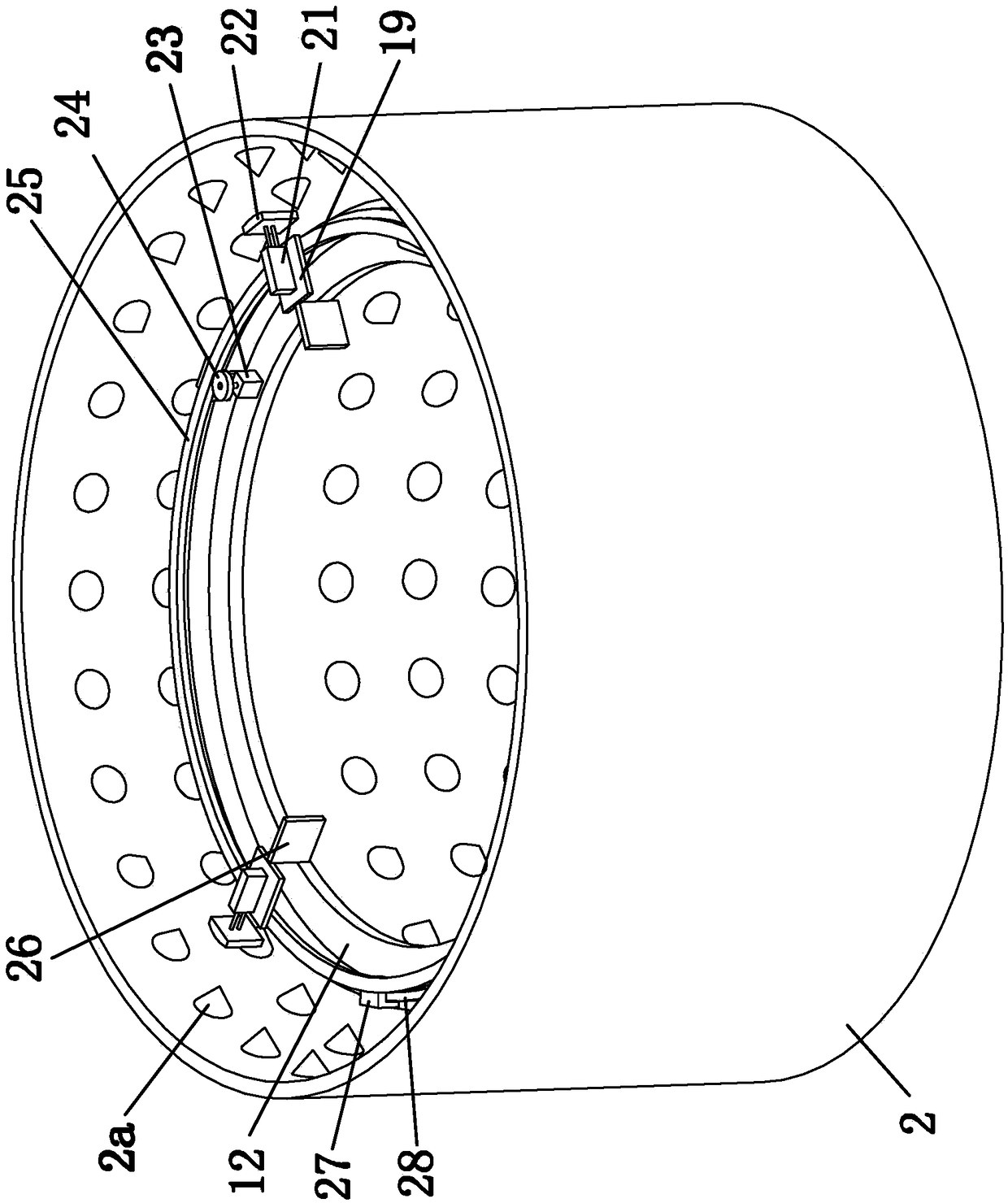

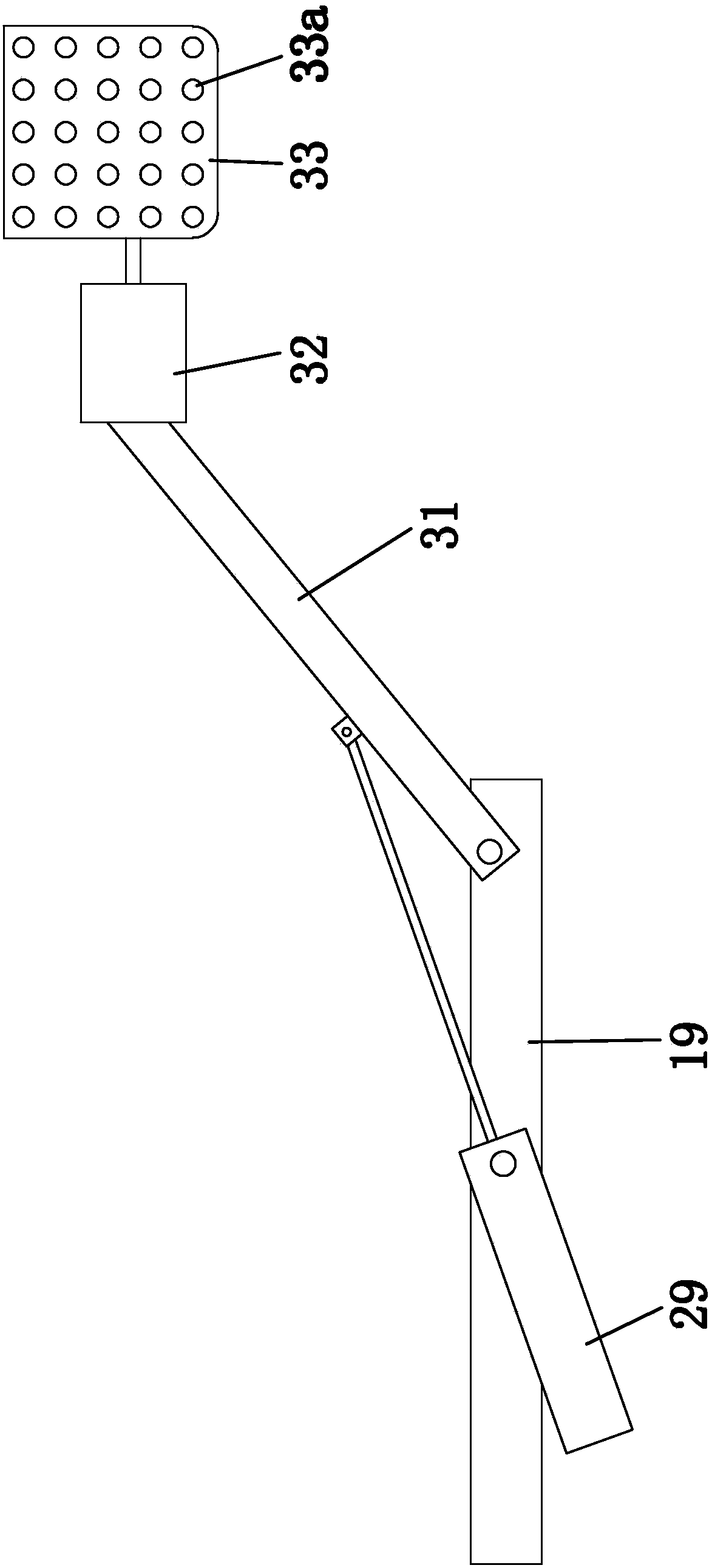

[0052] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0053] The road asphalt is composed of the following components by weight: 20-35 parts of petroleum asphalt, 40-55 parts of coal tar pitch, 0.2-0.5 parts of zinc oxide, 3-5 parts of straw fiber and 1-2 parts of resin.

[0054] Using this component, by using petroleum asphalt and coal tar asphalt as main components, and properly adding zinc oxide, straw fiber and resin, etc., the road asphalt can withstand high and low temperature environments and has good performance.

[0055] The parts by weight of each component are as follows: 28 parts of petroleum pitch, 47 parts of coal tar pitch, 0.3 part of zinc oxide, 4 parts of straw fiber and 1 part of resin.

[0056] Coal tar pitch is medium temperature coal tar pitch.

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com