Method for weakening cyclodextrin glucosyltransferase product inhibition

A glucose-based, product-inhibiting technology, applied in the direction of glycosyltransferase, transferase, biochemical equipment and methods, etc., can solve the problems of weakening product inhibition, cumbersome operation, membrane clogging, etc. Simple, mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

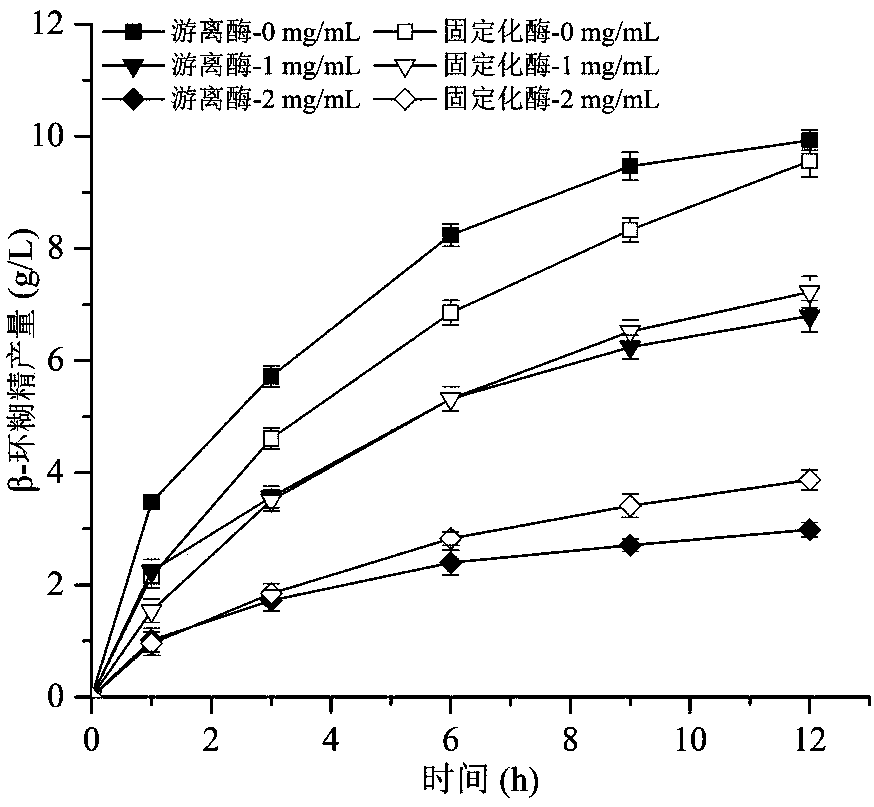

[0046] Example 1: Effect of Immobilized Enzyme on Cyclodextrin Glucosyltransferase Product Inhibition

[0047] Prepare 8% (w / w) gelatin solution with water, cool to 45°C, add cyclodextrin glucosyltransferase solution 10% (w / w) to mix evenly, pour it into a plate to a thickness of 3mm, and place it at 4°C Perform cooling and adsorption for 2 hours, cut into small pieces after forming a gel film, soak and cross-link with 0.25% glutaraldehyde solution at 25°C for 1 hour. Wash with water and set aside. The free enzyme and the prepared immobilized enzyme were analyzed for product inhibition. ( figure 1 Production of cyclodextrins for free and immobilized enzymes at different concentrations of cyclodextrin inhibitors)

[0048] From figure 1It can be seen that in the absence of cyclodextrin inhibitors, the cyclodextrin yield of free enzyme acting on maltodextrin at different time points is greater than that of gelatin-immobilized enzyme; the final concentration of 1mg / mL is added...

Embodiment 2

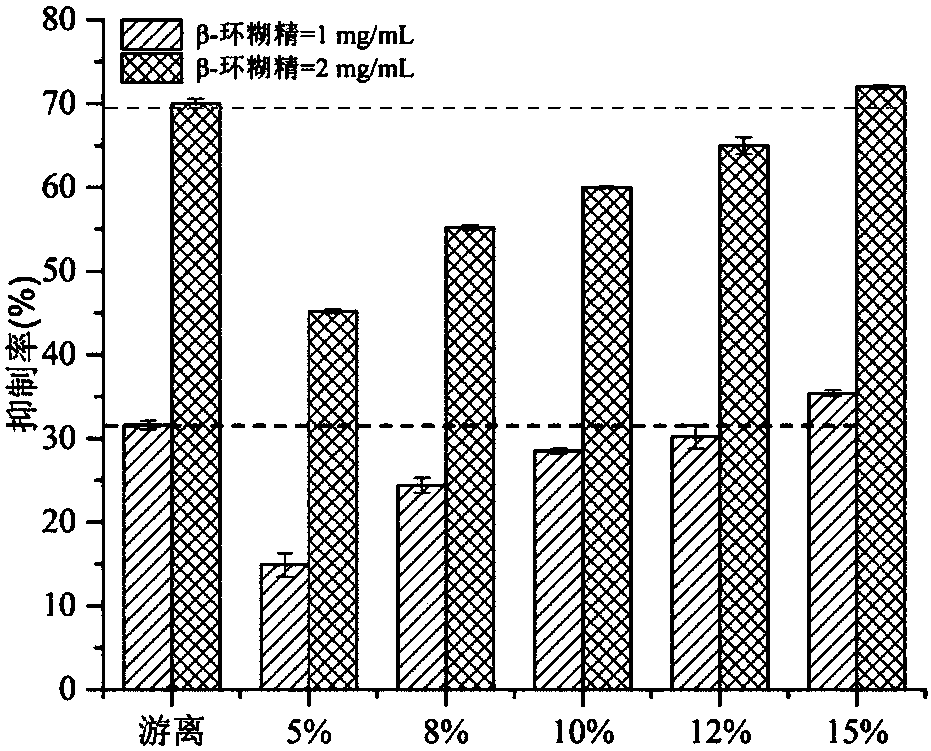

[0049] Example 2: Effect of Gelatin Concentration on Cyclodextrin Glucosyltransferase Product Inhibition

[0050] Prepare a 5%-15% (w / w) gelatin solution with water, cool to 45°C, add cyclodextrin glucosyltransferase solution 10% (w / w) to mix evenly, and immediately pour it into a plate to a thickness of 3mm. Place at 4°C for cooling and adsorption for 2h, cut into small pieces after forming a gel film, soak and cross-link with 0.25% glutaraldehyde solution at 25°C for 1h. Wash with water and set aside. The free enzyme and the prepared immobilized enzyme were analyzed for product inhibition. ( figure 2 Product inhibition of immobilized enzymes prepared for different concentrations of gelatin during reaction for 12 hours)

[0051] From figure 2 It can be seen that, when the gelatin concentration is low (5%-12%), the inhibition rate caused by the presence of 1mg / mL or 2mg / mLβ-cyclodextrin is lower than that of the free enzyme, and when the gelatin concentration is 15%, the...

Embodiment 3

[0053] Example 3: Effect of Temperature on the Activity of Immobilized Cyclodextrin Glucosyltransferase

[0054] Prepare 8% (w / w) gelatin solution with water, cool to 45°C, add cyclodextrin glucosyltransferase solution 10% (w / w) to mix evenly, pour it into a plate to a thickness of 3mm, and place it at 4°C Perform cooling and adsorption for 2 hours, cut into small pieces after forming a gel film, soak and cross-link with 0.25% glutaraldehyde solution at 25°C for 1 hour. Wash with water and set aside.

[0055] The free enzyme and the prepared gelatin-immobilized enzyme were respectively reacted at different temperatures (30-80°C) to measure the cyclization activity, and the highest cyclization activity was set as 100%, and the relative activity was calculated, taking the temperature as the horizontal Coordinates, relative activity is plotted as the ordinate to determine the optimum temperature of free enzyme and immobilized enzyme. ( Figure 12 Influence of temperature on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com