Internal combustion engine particulate filter control system

A particle filter and control system technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of limited accuracy, lack of consideration, and less correction, so as to improve system safety, reduce costs, improve The effect of reliability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific drawings and embodiments.

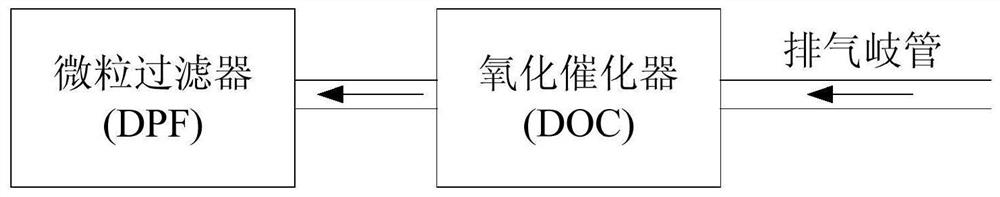

[0042] figure 1 Among them, the exhaust gas of the internal combustion engine passes through the exhaust manifold first through the oxidation catalyst (DOC for short), and then through the particulate filter (also known as the particulate filter, DPF for short) to meet the national exhaust emission standards.

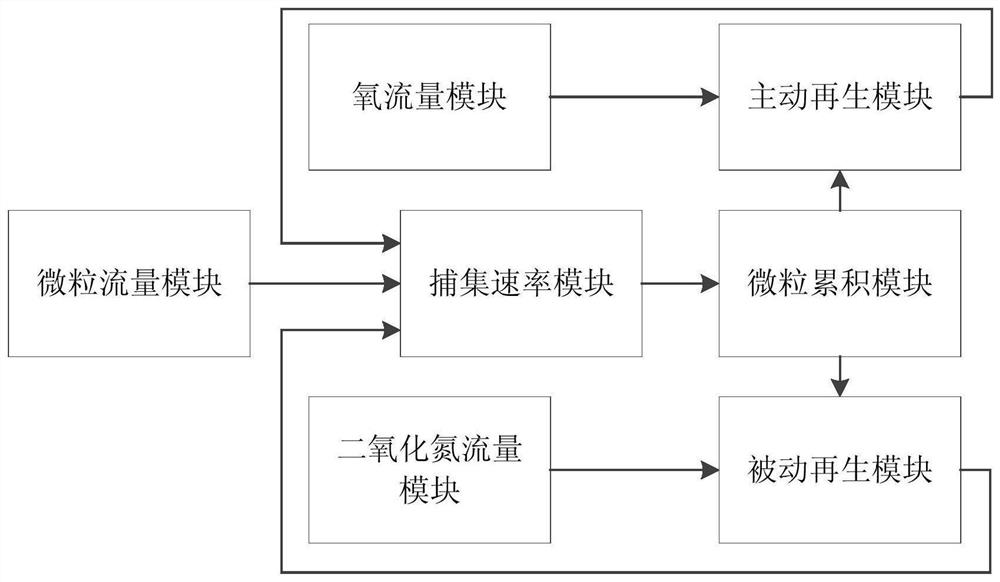

[0043] figure 2 It is a schematic diagram of the internal combustion engine particulate filter control system. The particulate filter control system of an internal combustion engine includes a particulate flow module, an oxygen flow module, a nitrogen dioxide flow module, an active regeneration module, a passive regeneration module, a capture rate module and a particulate accumulation module.

[0044] The particle flow module is used to calculate the particle emission flow of the exhaust gas of the internal combustion engine before treatment;

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com