Low-frequency magnetite material unit structure and its combination device

A technology of unit structure and special materials, applied in circuit devices, electrical components, inductors, etc., can solve the problem of low power level and achieve the effect of wide tuning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: A magnetic material unit structure.

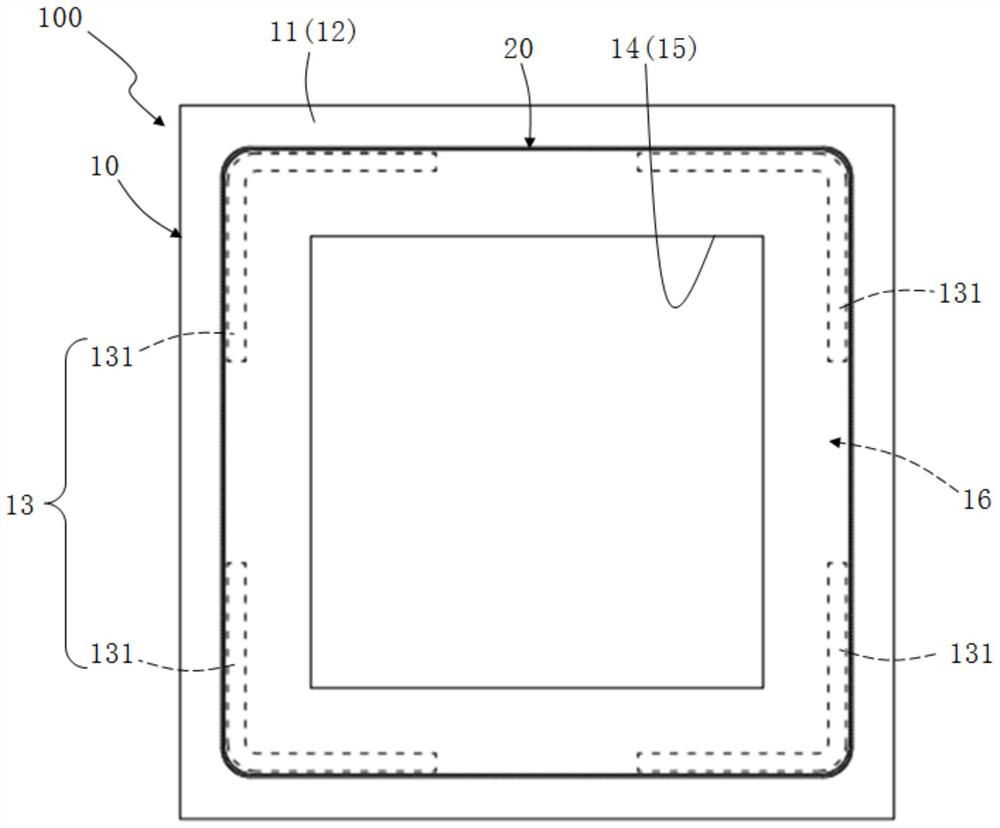

[0047] A magnetic material unit structure that can be used for wireless energy transmission of high-power electric vehicles at a working frequency of 85KHz, which is composed of a plexiglass plate (insulating medium plate 10), a litz wire (metal wire 20) and a capacitor (lumped parameter electronic components).

[0048] The main steps for the preparation of the unit structure of the magnetite material include:

[0049] The Litz wire was used to perform multiple dense windings on the side of the plexiglass plate, and 79 turns were wound, and then capacitors were welded at the head and tail ends of the Litz wire.

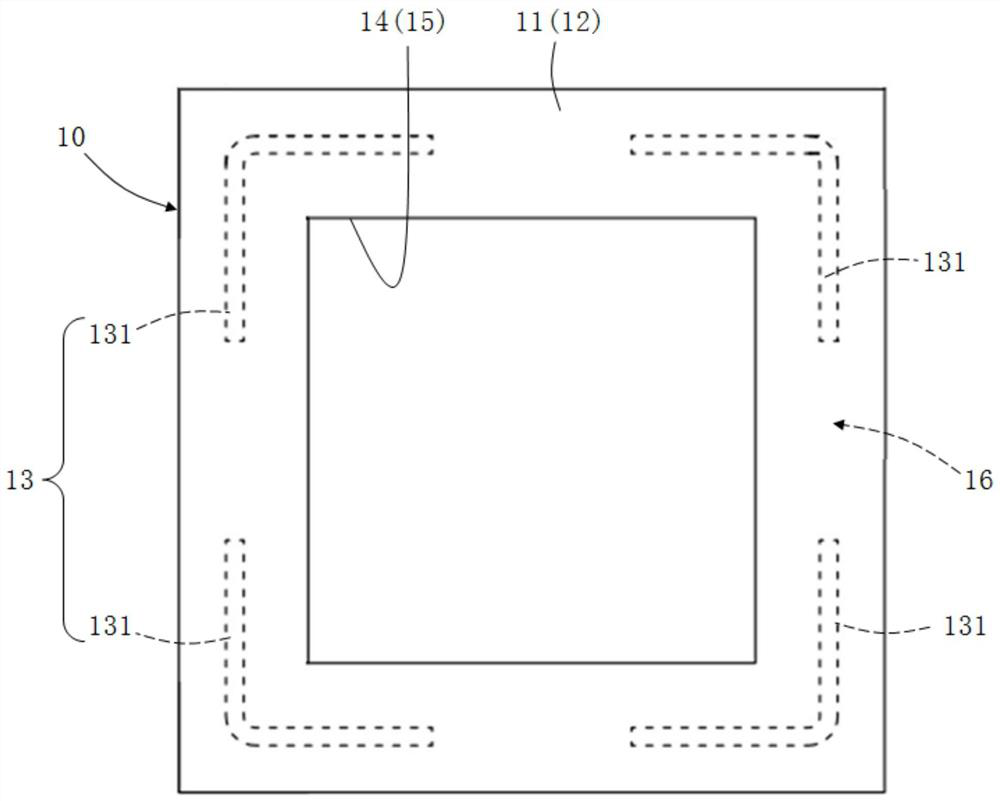

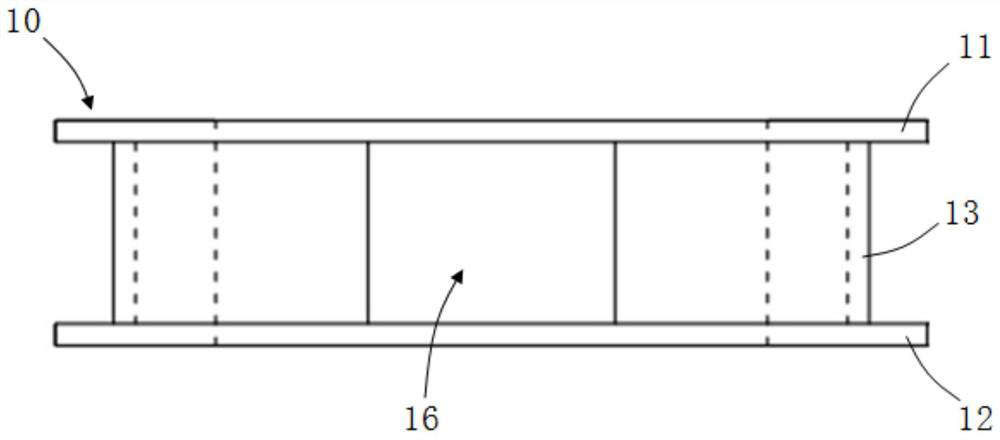

[0050] Among them, the plexiglass plate structure used in the magnetic material unit structure 100 of the present invention is as follows: figure 1 As shown, the material is polymethyl methacrylate (PMMA). The geometric parameters of this plexiglass plate are as follows: the length of the plate is 120mm, th...

Embodiment 2

[0053] Embodiment 2: A magnetite material unit structure assembly device composed of the magnetite material unit structure in embodiment 1.

[0054] A low-frequency magnetite overall material that can be used for wireless power transmission of high-power electric vehicles at a working frequency of 85KHz. like Figure 5 , Image 6 , showing a 5×5 array of low-frequency magnetite material unit structure combination devices formed by periodically replicating 25 magnetite material unit structures in Example 1 on a two-dimensional plane; wherein, the low-frequency magnetic The total length and total width of the Meteor material unit structure combination device are both 600mm, and the total thickness is 31mm.

[0055] like Figure 7 As shown, it shows the change of the effective magnetic permeability measured by the low-frequency magnetic material unit structure combination device of the present invention with frequency. Depend on Figure 7 It can be seen that the experimental...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com