A three-process CNC engraving machine

A CNC engraving machine and engraving machine technology, applied in engraving, motor vehicles, processing models, etc., can solve the problems of easy collision of workpieces and difficult to clean dust, and achieve the effect of saving man-hours, stable discharging process and clean workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

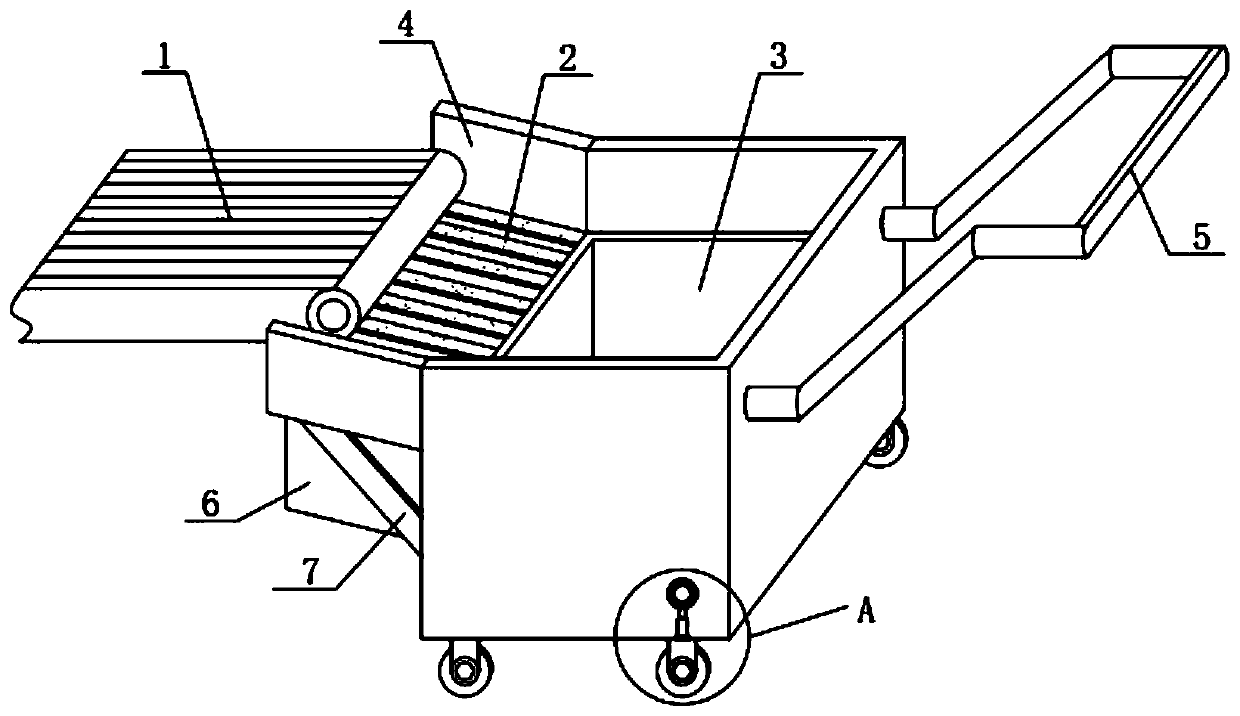

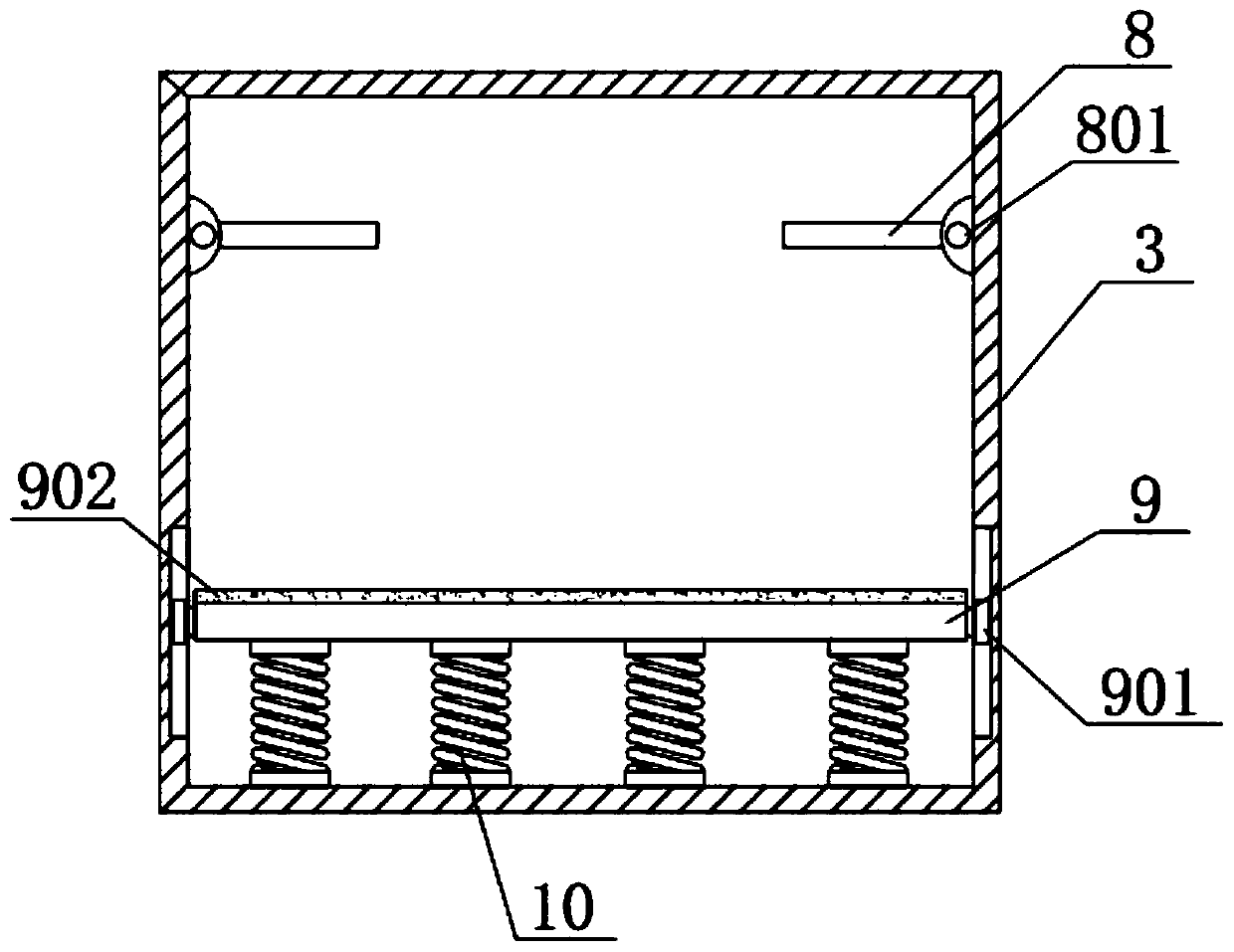

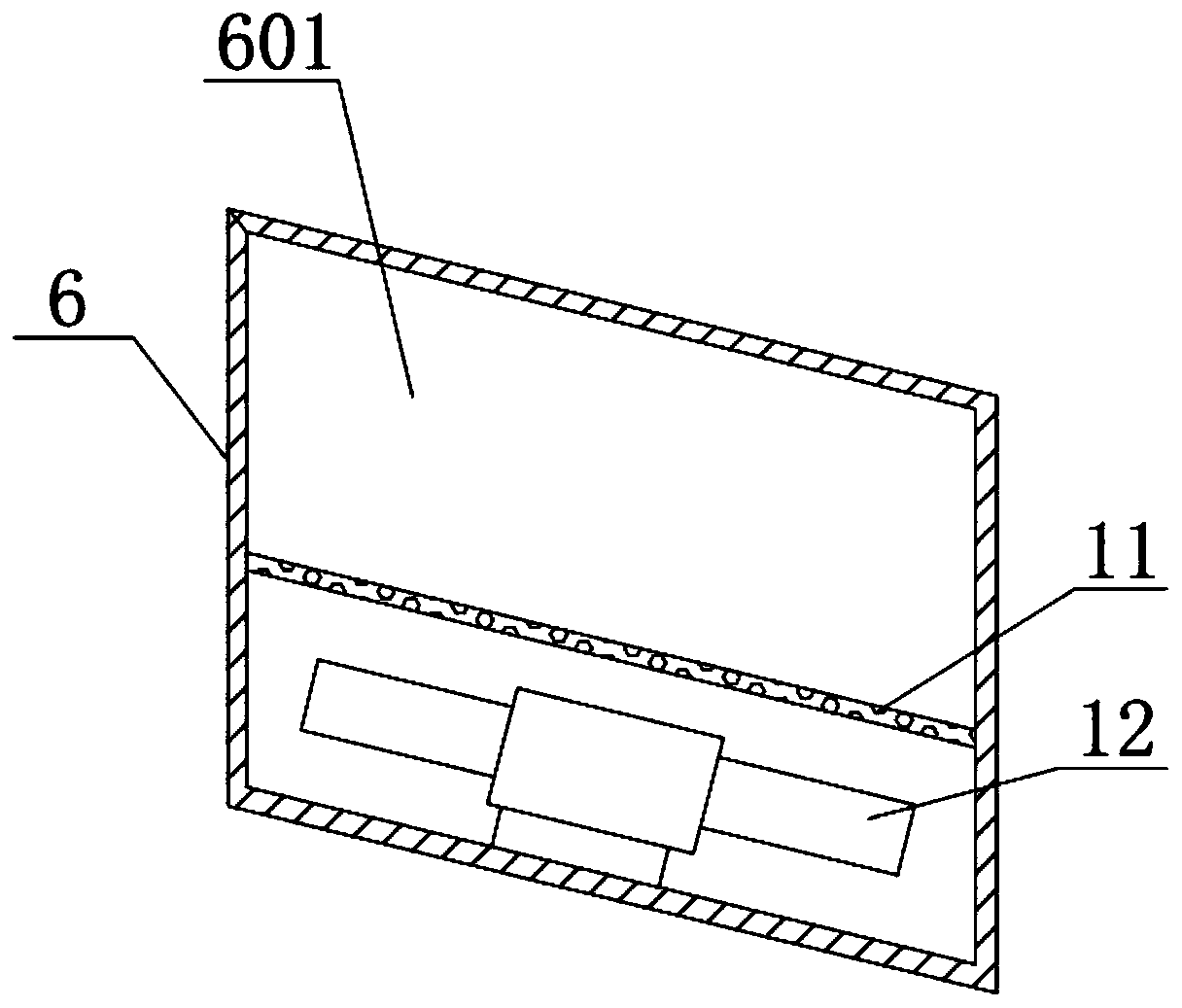

[0022] like Figure 1 to Figure 4 As shown, a kind of three-process numerical control engraving machine described in the present invention comprises machine tool, engraving motor and discharge conveyer belt 1 and controller, and engraving motor is installed on the lathe through drive mechanism, and the right side of lathe is equipped with discharge conveying Belt 1, the controller is used to control the work of the engraving machine; one end of the discharge conveyor belt 1 is provided with a blanking grid plate 2, the cross section of the blanking grid plate 2 is a wave-shaped structure, and the workpiece falls to the blanking grid When the grid plate 2 is on, the preliminary separation of the debris and the workpiece can be achieved. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com