Graphite protection board for ingot crucible

A graphite shield and crucible technology, which is applied in the field of polysilicon ingot furnace equipment, can solve the problems of deformation and damage of the cover plate, and the shield plate is easily damaged, and achieves the effects of saving production costs, facilitating assembly and disassembly, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

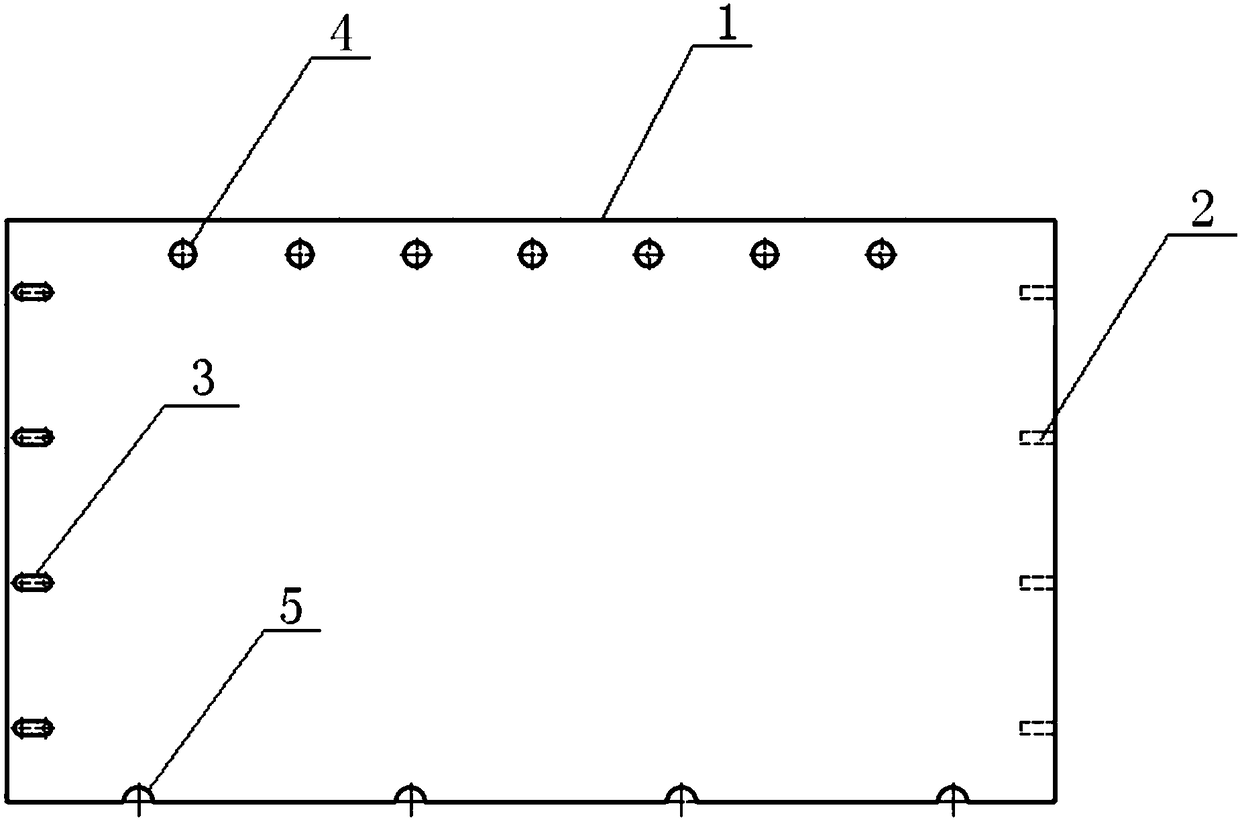

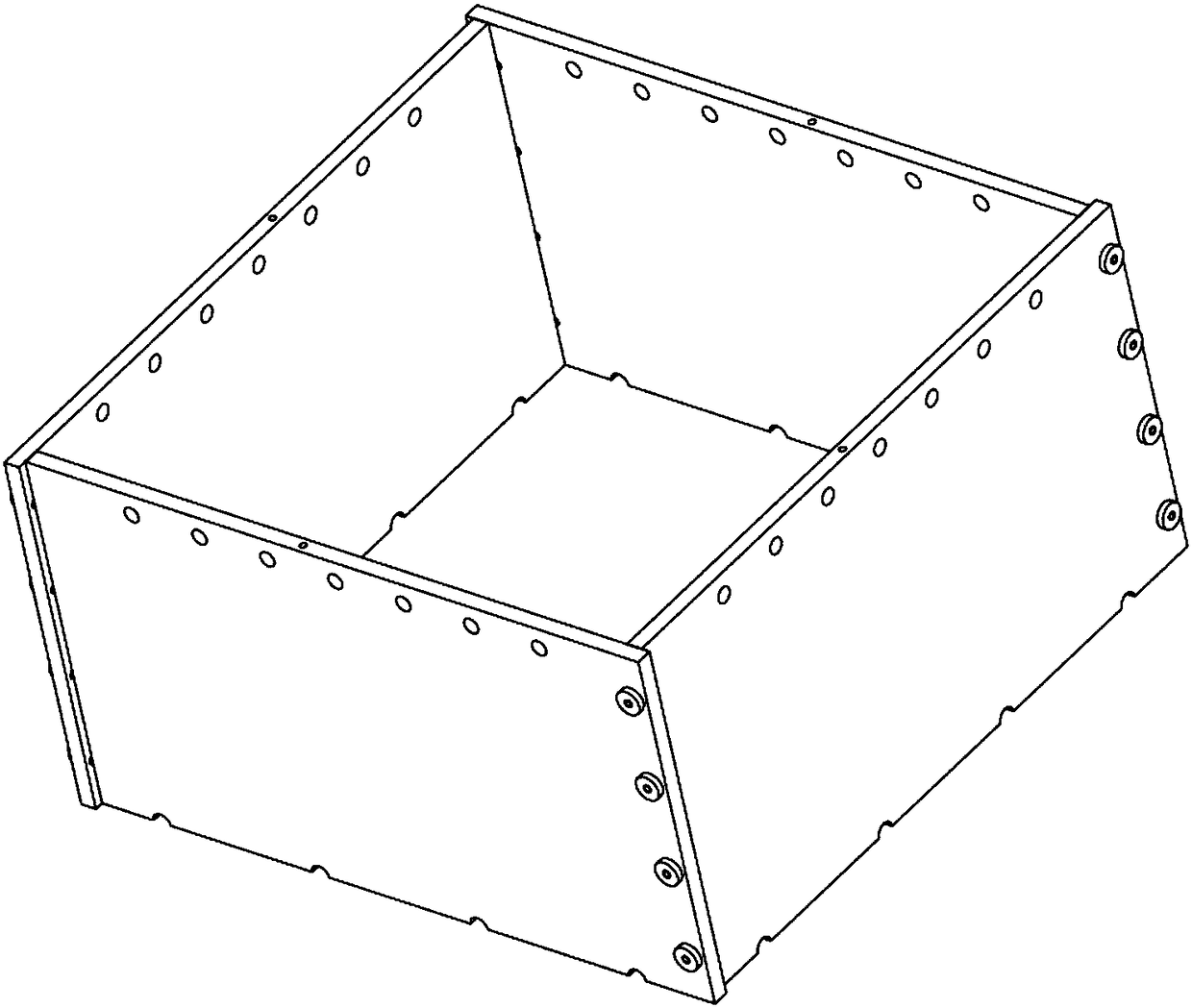

[0024] Such as figure 2 As shown, when in use, four graphite shields 1 are sequentially connected to form a cuboid space that can surround the crucible, and the bolts pass through the positioning holes 3 and cooperate with the threaded holes 2 on the left adjacent graphite shield 1 to realize two The connection of the graphite guard plate 1; after the assembly is completed, cover the cover plate for polysilicon ingot casting. During the ingot casting process, argon gas is continuously introduced to the surface of the silicon liquid through the air hole 4, and the precipitated impurities are discharged through the air flow, thereby improving the ingot casting process. quality;

[0025] When the bolt expands due to thermal expansion, there will be a gap in the anti-breakage groove to allow the bolt to play a certain buffer role; and when the bolt breaks in the threaded hole 2, the bolt can be taken out from the anti-breakage groove without damage to the crucible The shield is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com