Vehicle glass edge grinding device

A technology for automotive glass and edging, which is used in grinding/polishing safety devices, grinding machines, grinding workpiece supports, etc., can solve problems such as reducing the efficiency of grinding and increasing the steps of glass grinding, so as to improve the efficiency of grinding and reduce Operation steps, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

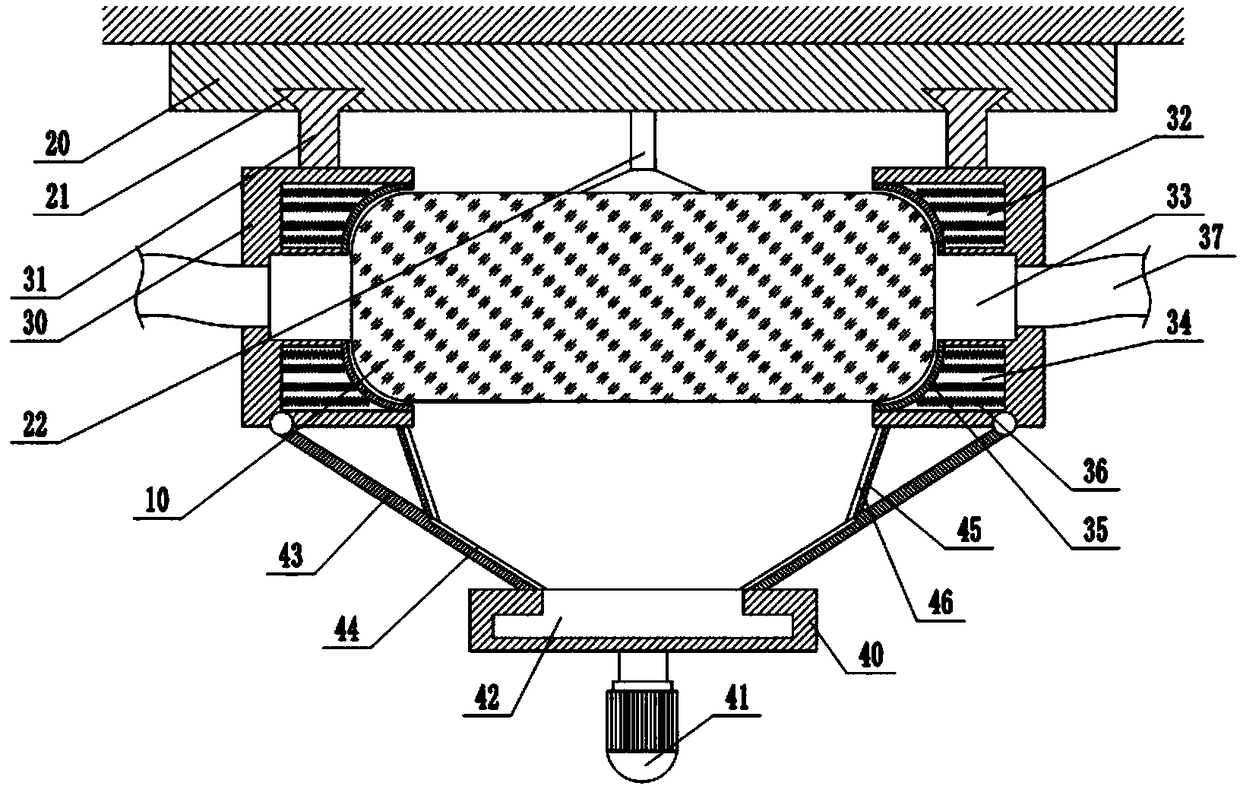

[0034] like figure 1Shown is Embodiment 1 of the present invention, and a kind of edging device of automobile glass is announced, and this device comprises the positioning plate 20 that is arranged horizontally, and wherein positioning plate 20 is fixed on the machine frame, is connected with polishing below positioning plate 20. Box 30, wherein the length of the polishing box 30 is less than the length of the square glass 10 to be polished, and the height is greater than the thickness of the square glass 10 to be polished. A guide rail 31 is provided in the direction, and a dovetail groove 21 for the guide rail 31 to slide is provided on the lower end surface of the positioning plate 20 . In order to simultaneously polish the four sides of the square glass 10, four grinding boxes 30 are arranged below the positioning plate 20, and are respectively positioned around the square glass 10; 10 of 22 for suction cups.

[0035] The specific setting of the grinding box 30 is that t...

Embodiment 2

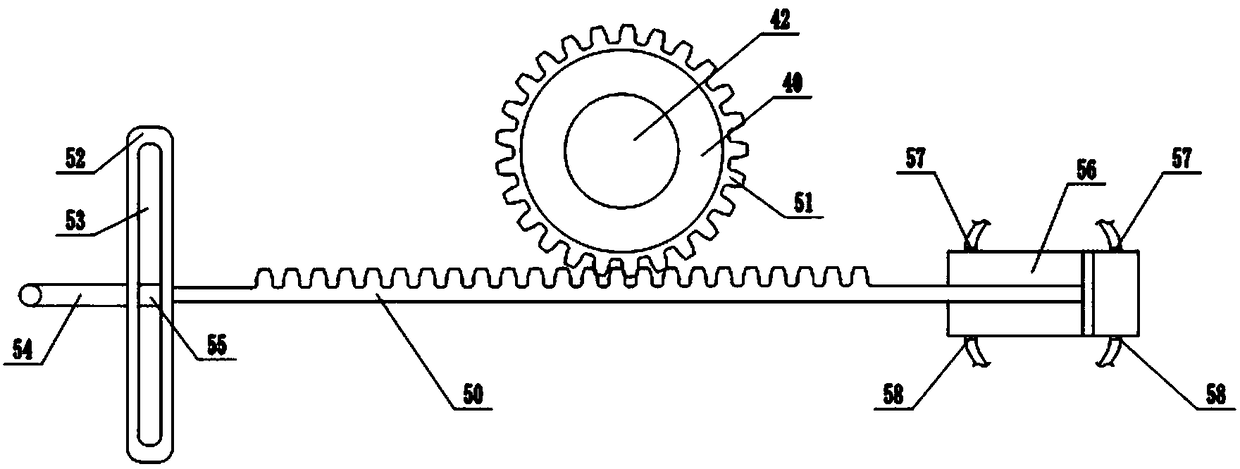

[0041] like figure 2 Shown is Embodiment 2 of the present invention, and the difference from Embodiment 1 is that the driving device used in this embodiment is an intermittent motion mechanism, which includes a rack 50 slidably connected to the frame, and on the circumference of the turntable 40 An outer ring gear 51 meshing with the rack 50 is fixedly provided, and one end of the rack 50 is fixedly connected with a pull plate 52 vertically arranged to the rack 50, and a chute 53 is arranged on the pull plate 52, and a motor output connection is also provided. The shaft is vertically connected to the guide rod 54. Here, a motor with a lower rotating speed is selected. In addition, the guide rod 54 is provided with a slide block 55 that is slidably connected to the chute 53; The cylinder 56, wherein the cylinder 56 is horizontally arranged, and the side walls of the cylinder 56 on both sides of the piston of the cylinder 56 are provided with an inlet check valve 57 and an outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com