Alkali swelling and association type thickening agent and preparation method thereof

An alkali-swollen associative and thickener technology, applied in the direction of coating, can solve problems such as poor stability and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

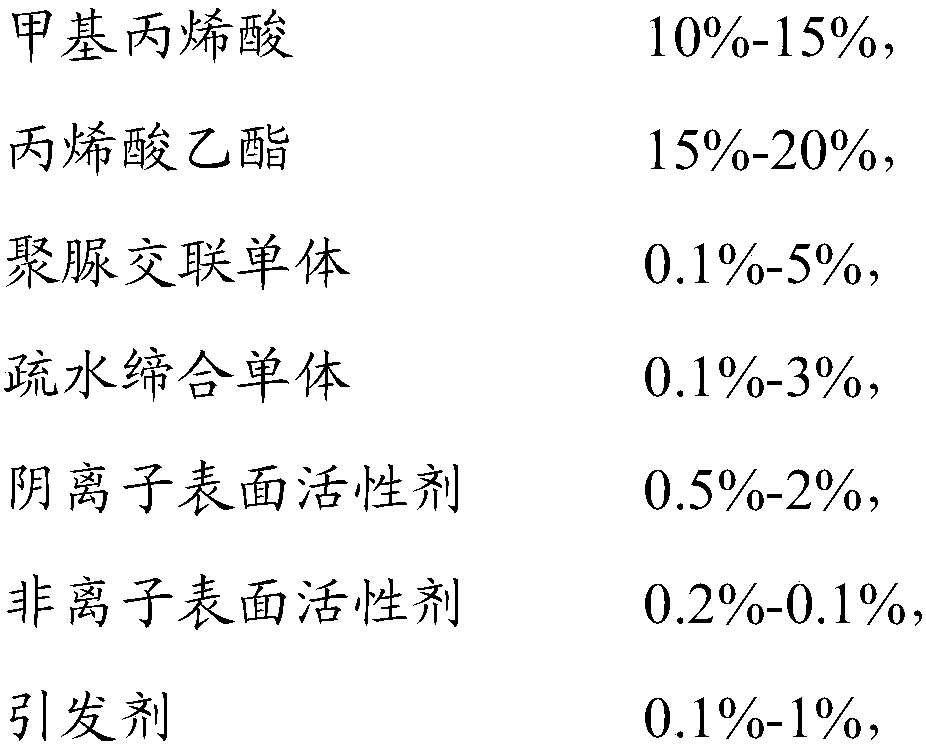

[0034] The present invention also includes a method for preparing an alkali-swellable associative thickener, comprising:

[0035] S101. The nonionic surfactant accounting for 0-100% of the total mass of nonionic surfactant and the anionic surfactant accounting for 0-100% of the total mass of anionic surfactant are placed in the reaction flask as a compound emulsifier, and then added Deionized water accounting for 30%-100% of the total mass of deionized water is stirred and heated to 80°C-90°C; in this step, no nonionic surfactant and / or anionic surfactant may be added;

[0036] S102. Add methacrylic acid, ethyl acrylate, polyurea crosslinking monomer, initiator, nonionic surfactant accounting for 0-100% of the total mass of nonionic surfactant, accounting for 0-100% of the total mass of anionic surfactant % anions and deionized water accounting for 0-70% of the total mass of deionized water are mixed to obtain a stable pre-emulsion, which is added dropwise into a reaction bott...

Embodiment 1

[0042] Preparation of Polyurea Crosslinking Monomer

[0043] 1) Add 84g (0.5mol) isophordionediamine (IPDA) into the reaction flask, then cool down the reaction system, when the temperature of the system drops to 10°C-15°C, start to drop 133.2g (0.6mol) ) isophordione diisocyanate (IPDI), the control drop time is 1 hour, after the drop is completed, it is incubated for 2h, and the discharging obtains the polyurea prepolymer;

[0044] 2) Take 217.2g of the above-mentioned polyurea prepolymer (0.2mol of isocyanate in the terminal group) and add it into the reaction flask, then control the temperature of the reaction system. When the system temperature is 25°C-30°C, start to drop 21.2g of acrylic acid β -Hydroxyethyl ester, control the dropping time to 1 hour, keep warm for 2 hours after the dropping is completed, and obtain the polyurea crosslinking monomer after discharging.

Embodiment 2

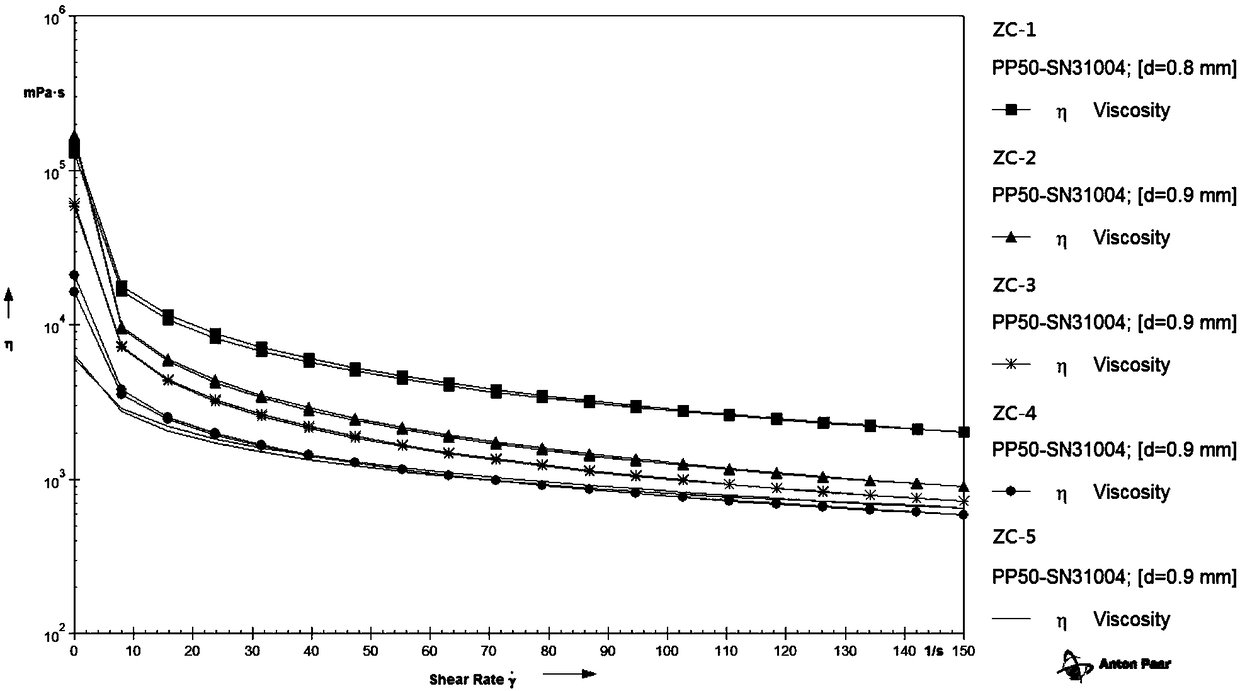

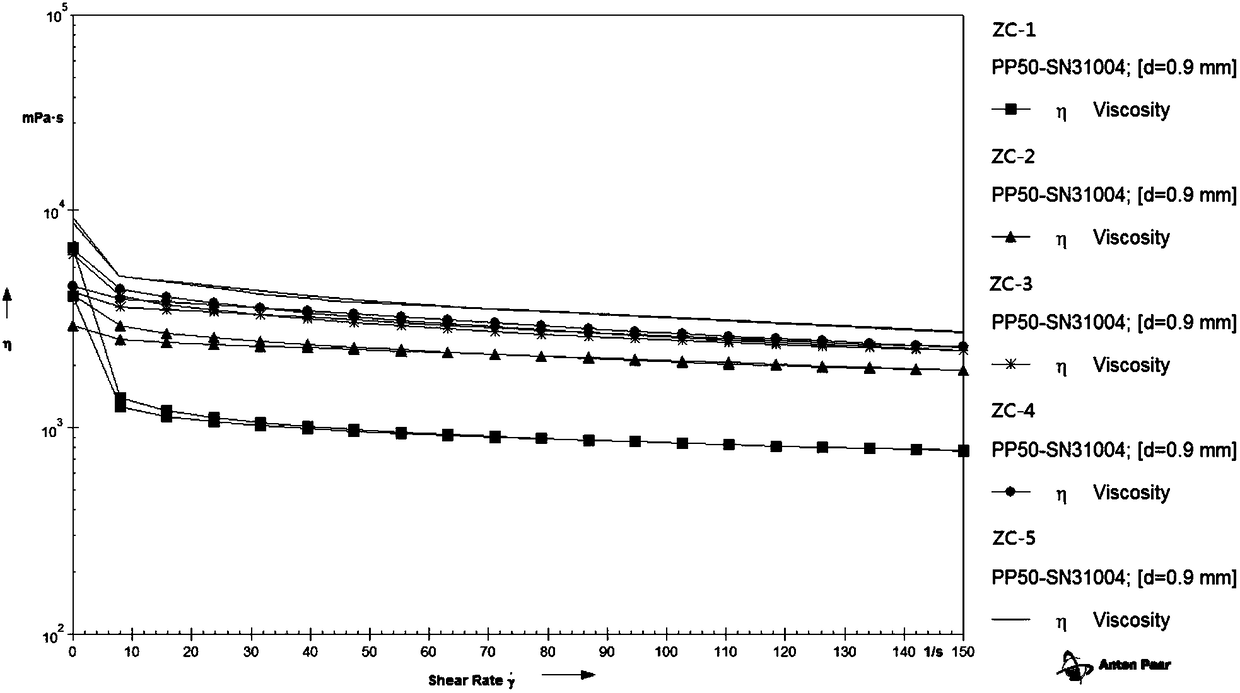

[0046] Alkali-swellable associative thickener ZC-1 was prepared according to the distribution ratio of each component in the following table 1

[0047] Table 1, ZC-1 group distribution ratio

[0048]

[0049]

[0050] S101. Put the nonionic surfactant and the anionic surfactant in the reaction flask as a composite emulsifier, then add deionized water accounting for 30% of the total mass of deionized water and stir to raise the temperature to 85° C.;

[0051] S102. Mix methacrylic acid, ethyl acrylate, polyurea crosslinking monomer, initiator and remaining deionized water to obtain a stable mixed solution, drop it into the reaction bottle within 3 hours, and keep it warm for 2 hours, that is Alkali-swellable associative thickener ZC-1 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com