High-impact polyethylene and processing method thereof

A high-impact, polyethylene technology, applied in the field of plastic modification, can solve the problems of high cost of impact-resistant polyvinyl chloride and high manufacturing cost of impact-resistant modifiers, and achieve low production cost, reduced production cost, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] High-impact polyvinyl chloride, based on 100 parts by weight, its raw material composition includes: 100 parts of PVC resin, 5 parts of highly branched polyethylene, 2 parts of chlorinated polyethylene, 1 part of dibutyltin dilaurate, stearic acid 1 serving.

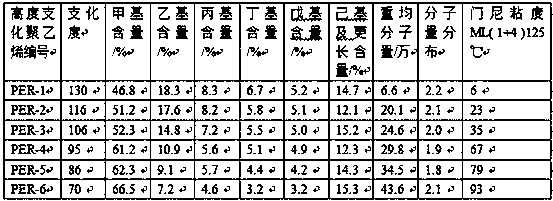

[0020] Wherein, the PVC resin is a PVC resin with a degree of polymerization of 1400; the number of the highly branched polyethylene used is PER-5.

Embodiment 2

[0022] High-impact polyvinyl chloride, based on 100 parts by weight, its raw material composition includes: 100 parts of PVC resin, 10 parts of highly branched polyethylene, 5 parts of chlorinated polyethylene, 0.5 part of di-n-octyltin dilaurate, stearin acid 2 parts.

[0023] Wherein, the PVC resin is a PVC resin with a degree of polymerization of 1600; the number of the highly branched polyethylene used is PER-4.

Embodiment 3

[0025] High-impact polyvinyl chloride, based on 100 parts by weight, its raw material composition includes: 100 parts of PVC resin, 15 parts of highly branched polyethylene, 7 parts of chlorinated polyethylene, 3 parts of tribasic lead sulfate, stearic acid 2 parts of barium, 0.5 parts of paraffin.

[0026] Wherein, the PVC resin is a PVC resin with a degree of polymerization of 1500; the number of the highly branched polyethylene used is PER-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com