Treatment method of circulating fluidized bed boiler multipoint bed temperature signal

A circulating fluidized bed and treatment method technology, applied in the field of control, can solve the problems of lowering control quality, deviation of average bed temperature, under-temperature alarm, etc., and achieve the effect of improving control quality, overcoming random disturbance, and good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

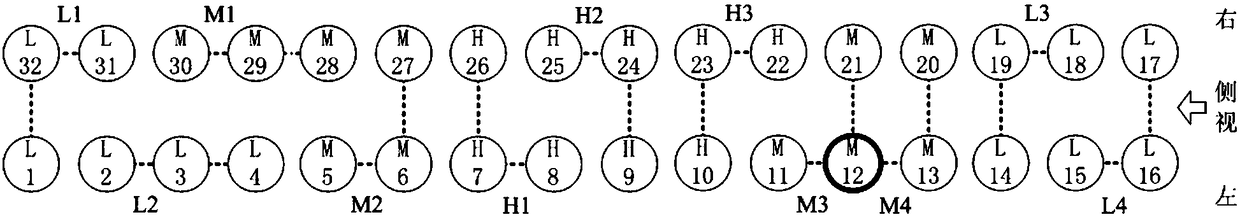

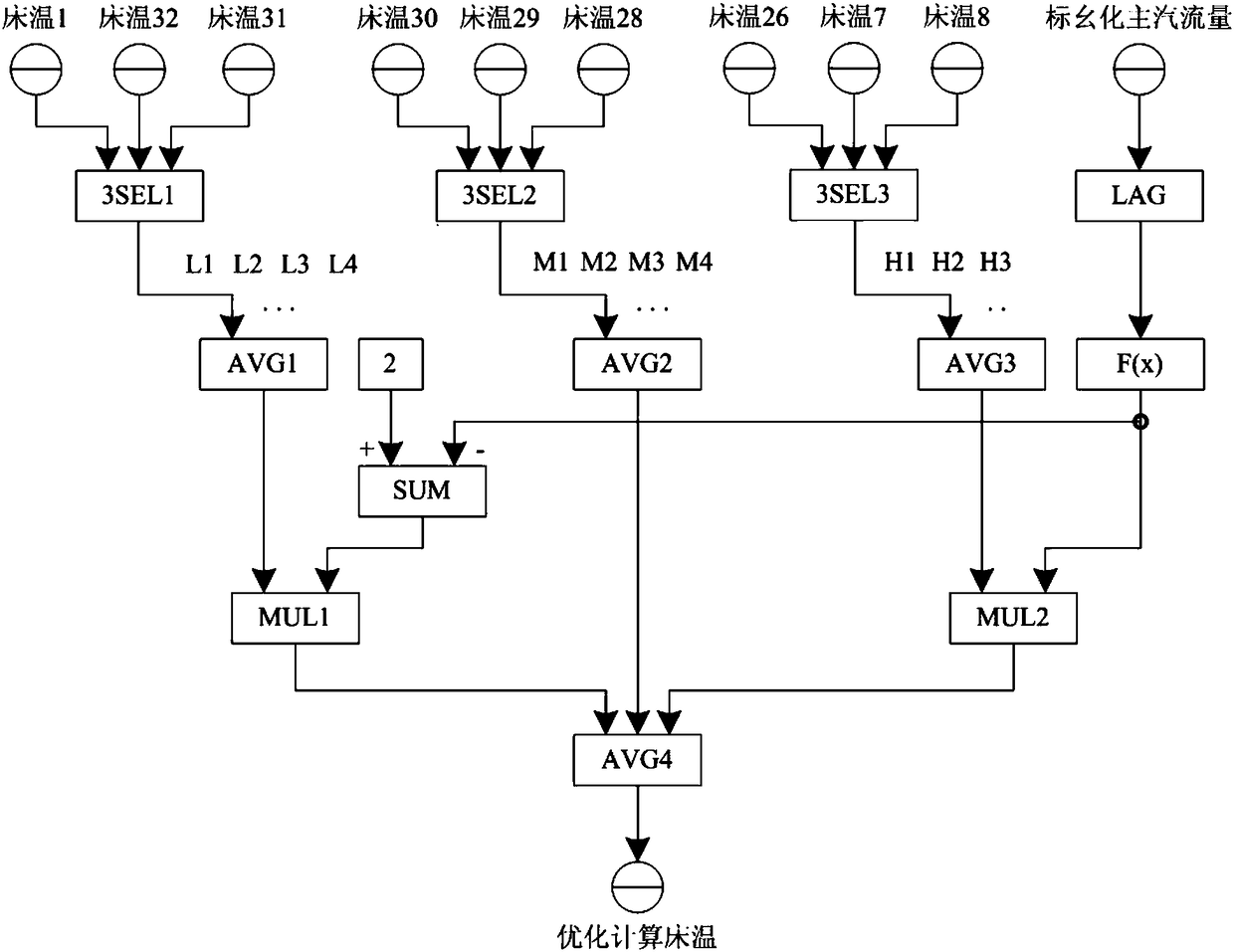

[0032] Aiming at the disadvantages of calculating the bed temperature signal by calculating the average value or the median value in the existing circulating fluidized bed boiler, the present invention proposes a multi-point bed temperature signal processing method of the circulating fluidized bed boiler. In this method, according to the distribution law of the deviation between the measured value of each bed temperature signal and the average value of all bed temperature signals, the bed temperature signals adjacent to the installation position are divided into groups of three into high temperature zone, normal temperature zone, and low temperature zone. One or several bed temperature signals can be repeatedly divided into different areas to ensure that all bed temperature signals can be divided. Then, the three bed temperature signals of each group were sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com