MVR (Mechanical Vapor Recompression) system with external energy compensation

A technology of external energy and compensation heating, which is applied in the direction of forced circulation evaporator, evaporator accessories, evaporation, etc., can solve the problem of the stability, continuity and reliability of the MVR system, and cannot maintain the continuous operation of the evaporation system. Zero loss and other issues, to achieve the effect of convenient start and stop, quick response and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

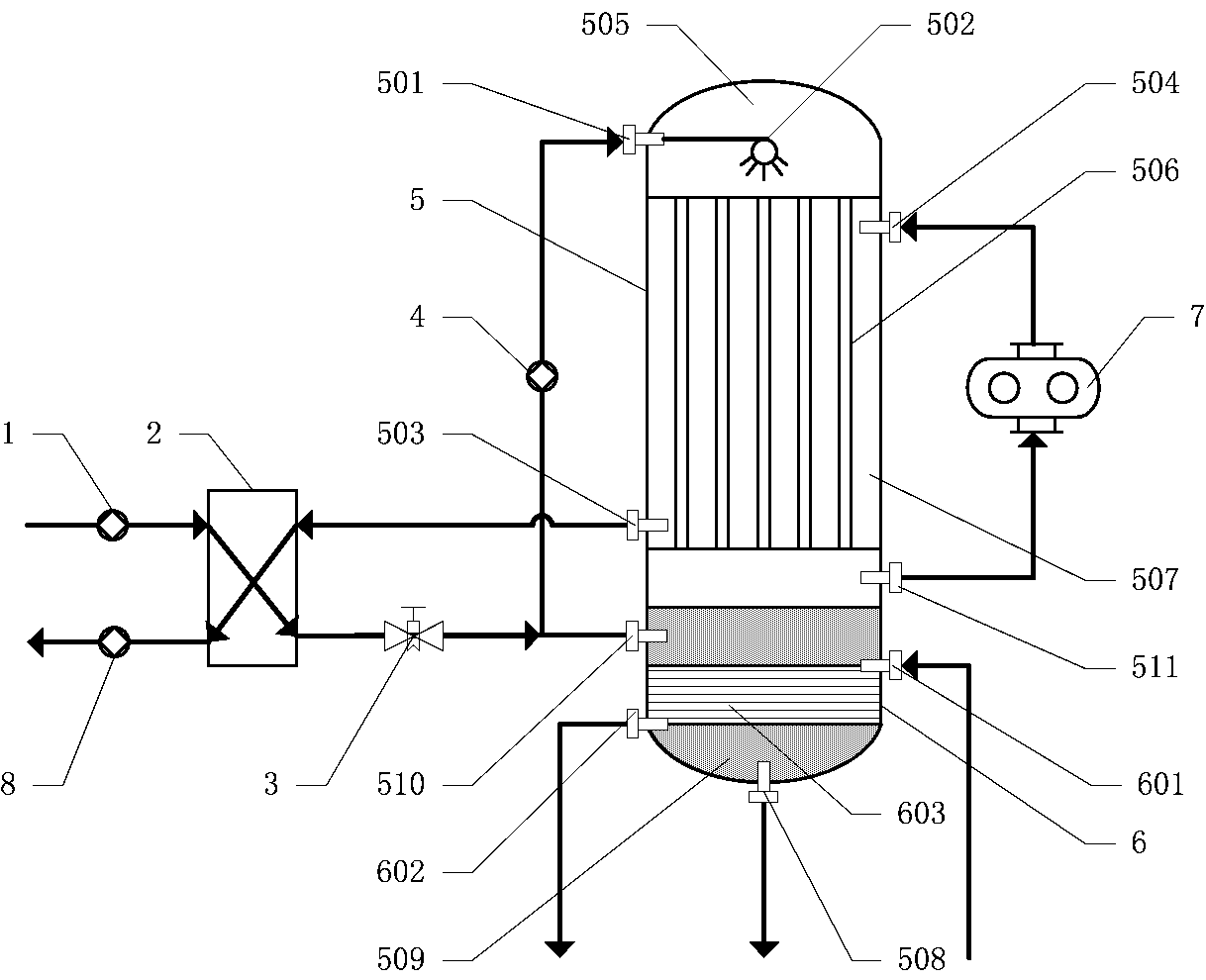

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] Such as figure 1As shown, the MVR system with external energy compensation described in the present invention includes water inlet pump (1), heat exchanger (2), water inlet valve (3), circulating water pump (4), evaporator (5 ), compensation heating device (6), MVR steam compressor (7), water outlet pump (8).

[0031] To further illustrate the specific implementation of the present invention, taking seawater desalination as an example, seawater at about 20°C first enters the heat exchanger (2) through the inlet pump (1) to exchange heat with condensed water, and the seawater temperature rises to about 45°C. Then the seawater at about 45°C is heated to about 80°C by the compensation heating device (6), enters the evaporator (5), and enters the cycle evaporation process. The steam-water mixture after seawater evaporation is separated, and the steam part is compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com