A circulating static pressure magnetorheological polishing device

The technology of magnetorheological polishing and excitation device is applied in the field of magnetorheological polishing, which can solve the problems of large volume and polishing of the inner wall of extremely thin pipes, and achieve the effect of reducing the volume, realizing the polishing operation, and reducing the generation of heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

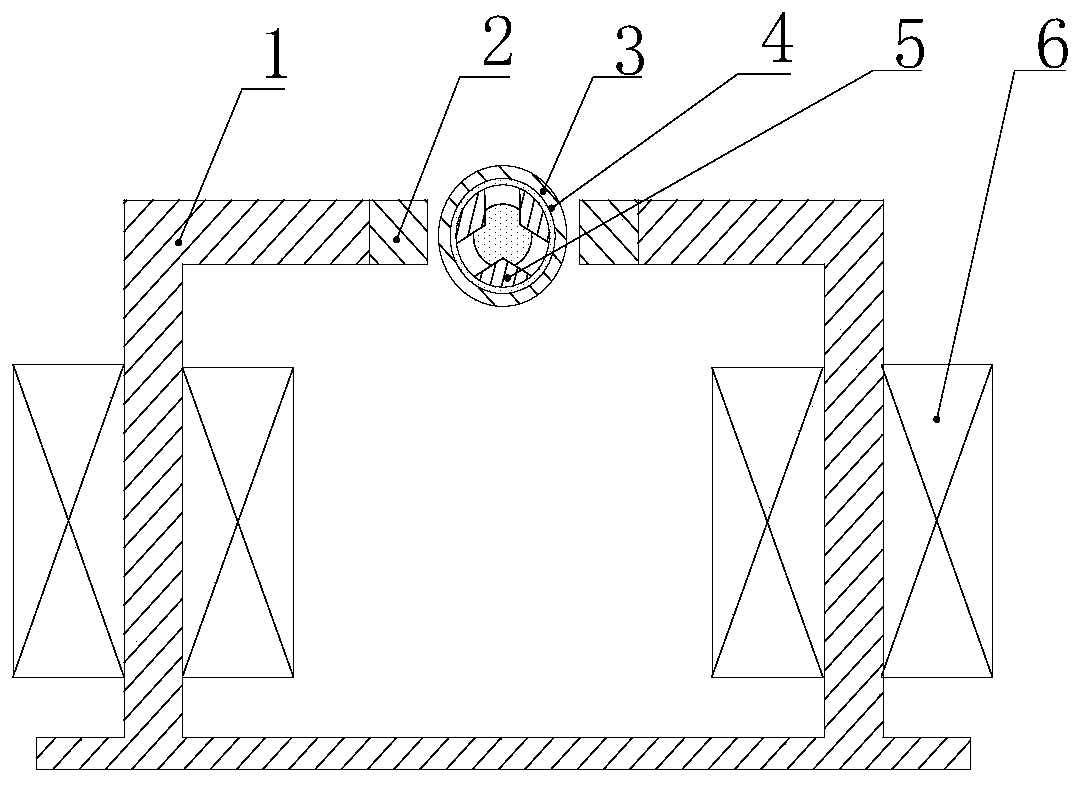

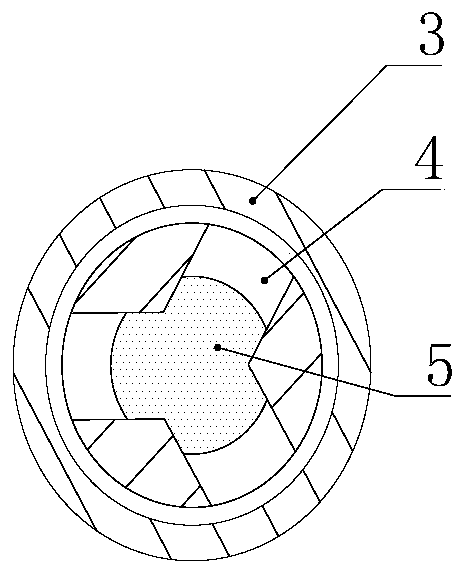

[0030] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0031] The invention provides a circulating static pressure magnetorheological polishing device, which utilizes the principle that the solidification degree of the magnetorheological fluid is affected by the magnetic field intensity within a certain range of magnetic field intensity to perform polishing. Under the action of a magnetic field, the magnetorheological fluid is in a semi-solid state, and the yield stress increases significantly, and within a certain range, the yield stress increases with the increase of the magnetic field intensity.

[0032] Such as figure 1 As shown, with the U-shaped iron core 1 as the base, the excitation coil 6 is wound on both sides of the U-shaped iron core 1, and the two ends of the opening of the U-shaped iron core are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com