3D (Three Dimensional) printing machine with material recycling and planting cleaning device

A technology of 3D printer and cleaning device, which is used in processing and recycling, manufacturing auxiliary devices, 3D object support structure, etc., can solve problems such as inability to use, inconvenient to use, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

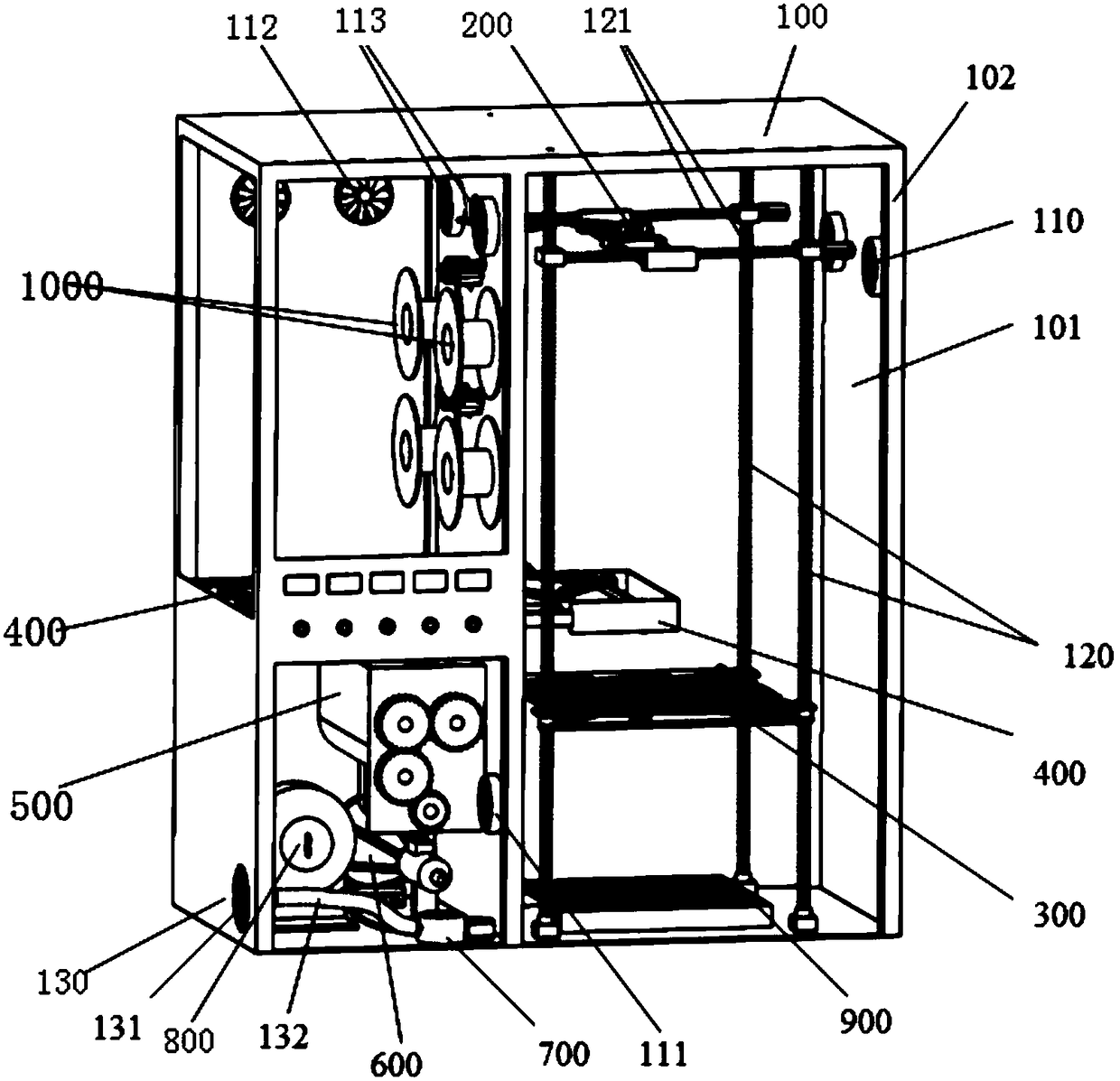

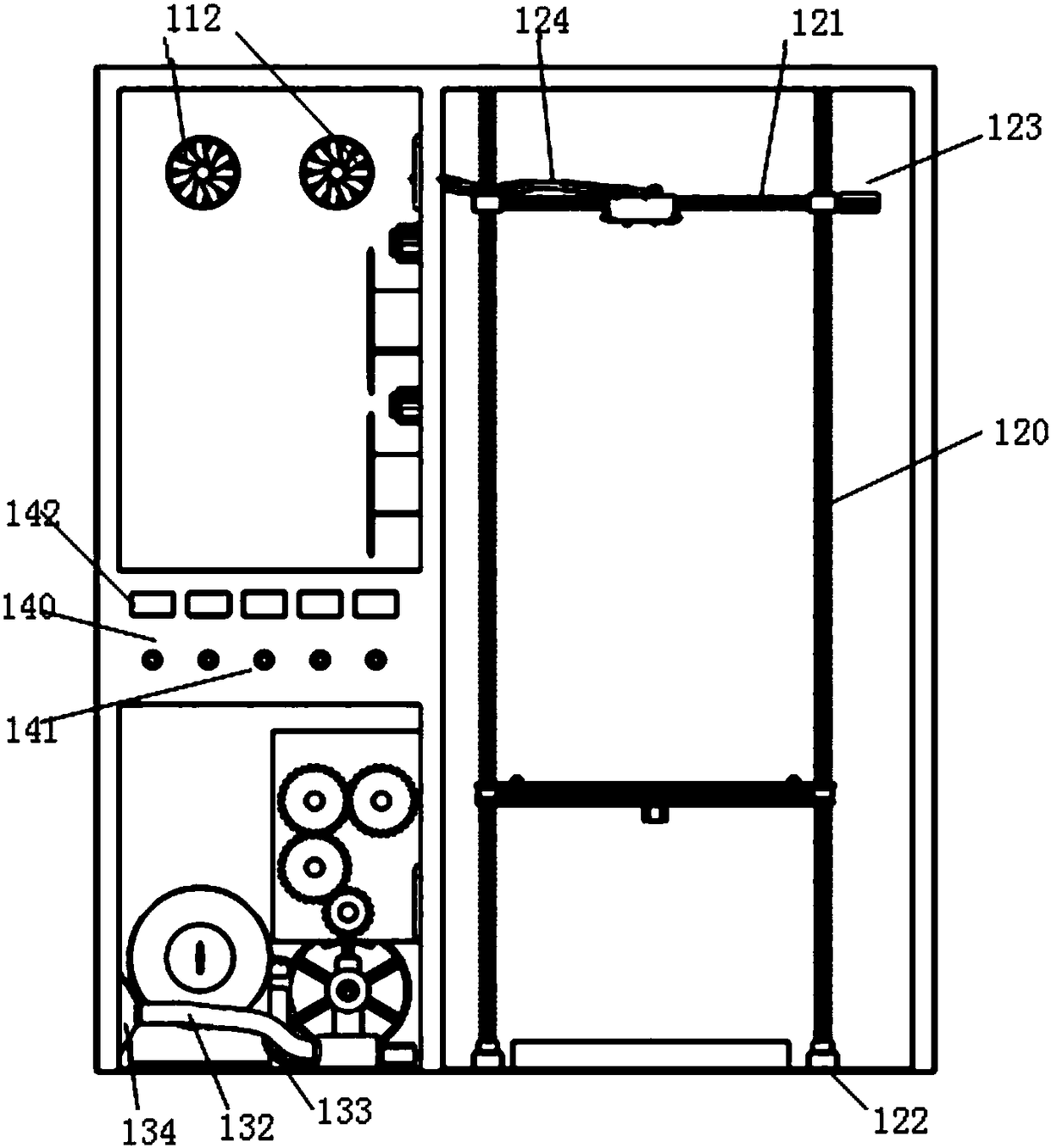

[0051] Example 1: Combining figure 1 and figure 2 See 3D printer main frame 100.

[0052]The printer main frame 100 includes a sheet metal shell 101, a support column 102, a fan (110-113), an internal structure ball screw 120, an air inlet 130, and a control panel 140. The sheet metal shell is fixed on the support column 102, and the right side of the printer is Fan 1 110 is installed on the sheet metal shell 101, fan 4 113 is installed on the upper part of the middle sheet metal shell 101, and fan 2 111 is installed on the lower part, and the fan 1 110, fan 2 111 and fan 4 113 work together to ensure the temperature of the molding chamber Stable; the rear sheet metal shell 101 is equipped with a fan 3 112 for dissipating the heat inside the printer; four ball screws 120 are installed in the main frame 100, the bottom of the ball screw 120 is provided with a mounting seat 122, and the upper part is installed with X direction ball screw 121, two stepping motors 123 are respe...

Embodiment 2

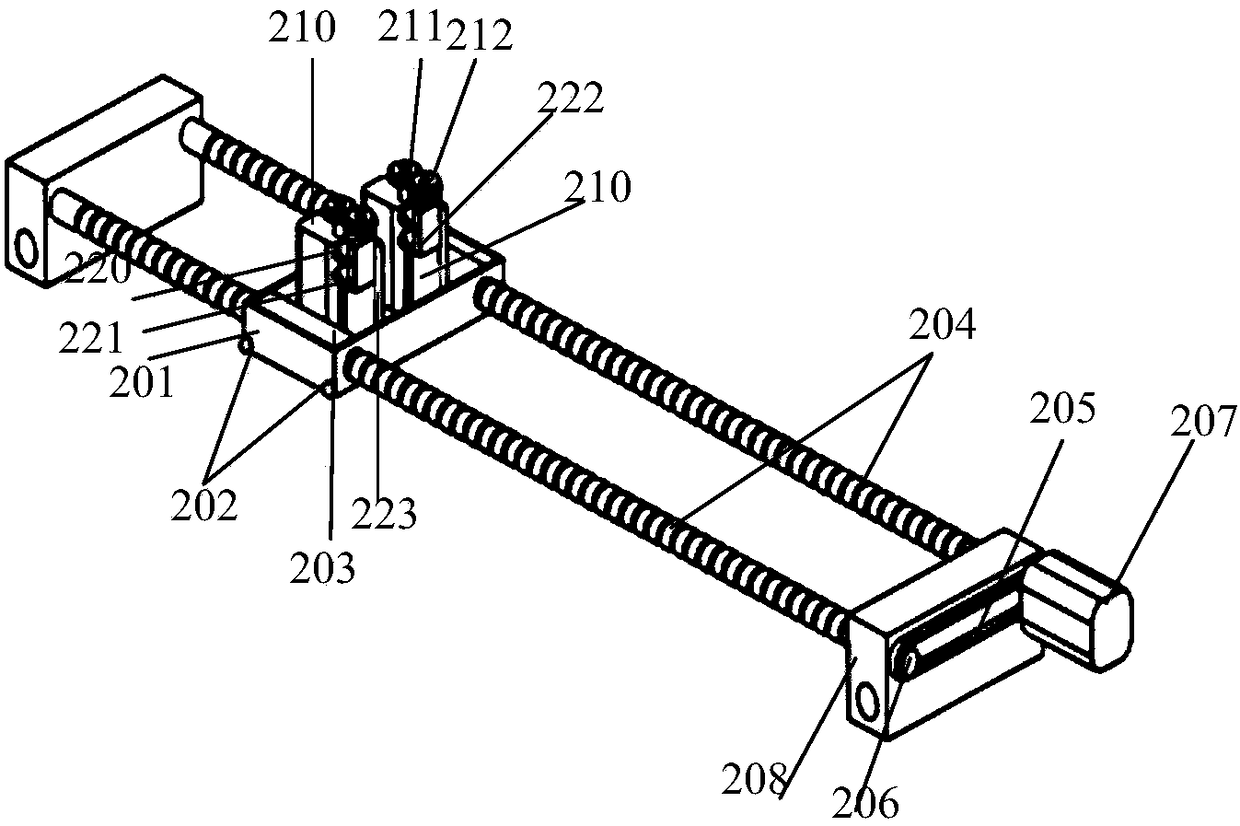

[0053] Embodiment 2: Combination image 3 , Figure 4 and Figure 5 See printing device 200 .

[0054] The printing device 200 includes a mounting frame 201, a ball screw thread 203, a DC motor 210, and a print head 224. Four temperature sensors 202 are installed at the four corners of the bottom of the mounting frame 201 to monitor the temperature of the printer forming chamber in real time. The mounting frame is provided with a ball screw thread. 203, and a Y-direction ball screw 204 is installed. In order to improve the accuracy of the synchronous movement of the ball screws, a timing belt 205 is used to connect two Y-direction ball screws 204, and a timing belt pulley 206 is provided. The timing belt pulley 206 is connected with the step The first motor 207 is connected, and the stepper motor 207 provides the power of the whole printing device. The Y-direction ball screw is equipped with a ball screw connection block 208, and the connection block 208 is connected with th...

Embodiment 3

[0055] Example Three: Combining Figure 6 and Figure 7 See print platform 300.

[0056] The printing platform 300 includes a slot-type printing plate 303 , a ball driver 310 and a stepping motor 2 320 . The four sides of the printing platform 300 are provided with temperature sensors 301, which are used to monitor the temperature of the molding chamber in real time. The surface of the printing platform 300 is provided with a groove-shaped printing plate 303. The printing nozzle 224 extrudes the fuse, and the fuse is formed on the printing plate 303, and Embedded in the groove, it helps the printed parts not to be deformed; the four corners of the printing platform 300 are provided with through holes 302, the ball screw 120 passes through the through holes 302, and four ball drivers (310-313) are installed under the through holes 302, The first ball driver 310 and the second ball driver 311 link to each other with the pulley driver 324 through the first synchronous belt 315;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com