Blowing-in and charging method of blast furnace

A technology for opening furnaces and charging blast furnaces, applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as poor air permeability of material columns, unfavorable smooth recovery, and slow recovery speed of air supply, so as to ensure air permeability and reduce fluctuations The effect of frequency and air volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

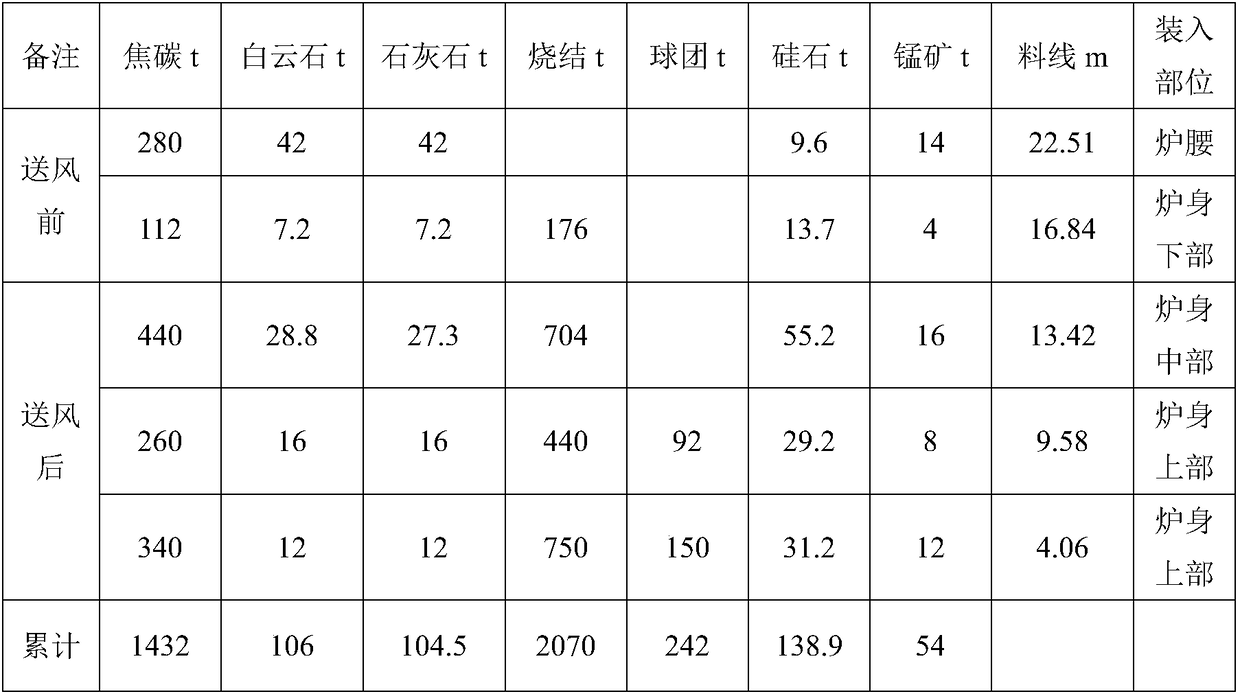

[0017] In order to explain the present invention better, the main content of the present invention is further illustrated below in conjunction with the opening process of the No. 7 blast furnace of Wuhan Iron and Steel Co., Ltd. ironworks in March, but the content of the present invention is not limited to the following examples.

[0018] This embodiment discloses a method for charging a seven-blast furnace, which specifically includes the following steps:

[0019] 1) Preparation before starting the furnace: adjust the angle of the opening machine (preferably 6° in this embodiment); surround the main ditch in front of the blast furnace with yellow sand; pad yellow sand and coke powder in the slag iron ditch; prepare to burn oxygen Place the yellow sand and coke powder in front of the sand mouth, and fix the baffle; clean the dry slag pit; burn the hot blast stove of the blast furnace before blowing the air, and ensure that the vault temperature of the hot blast stove before blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com