Connecting device and connecting structure of steel bars and mounting method of connecting structure

A connecting device and connecting structure technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of high connection strength, poor quality controllability, high cost, and achieve good seismic performance, convenient operation, and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

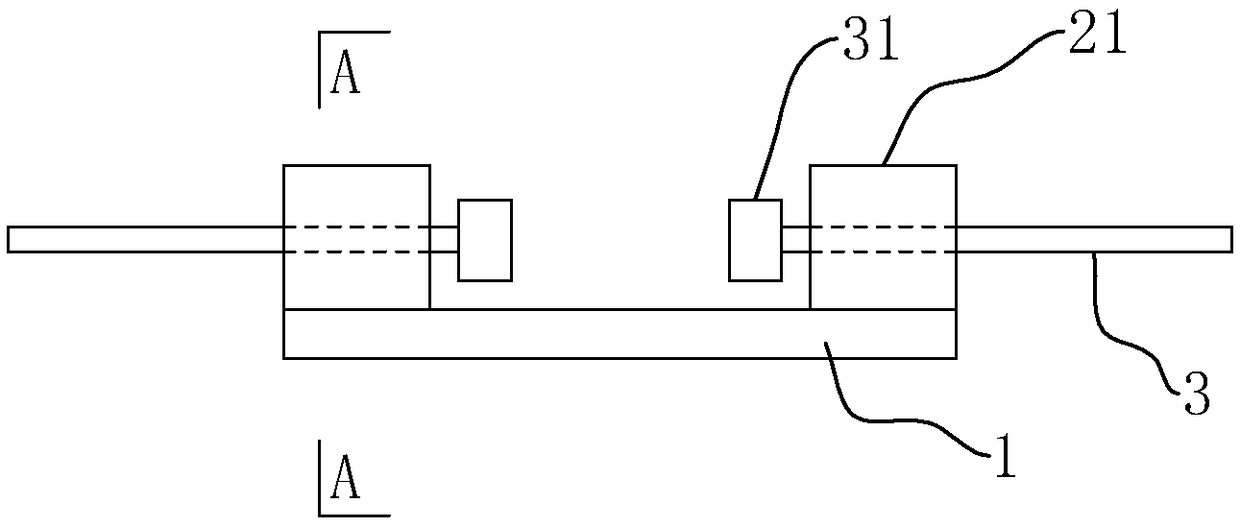

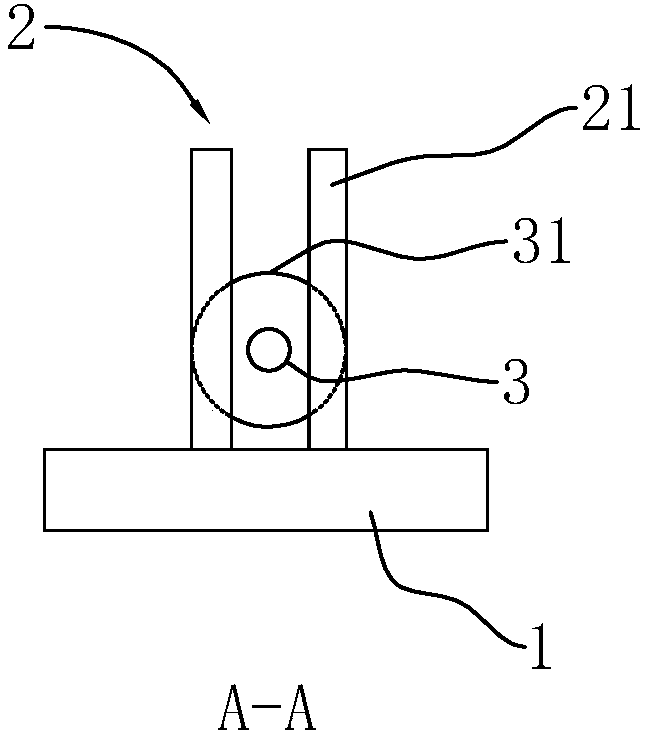

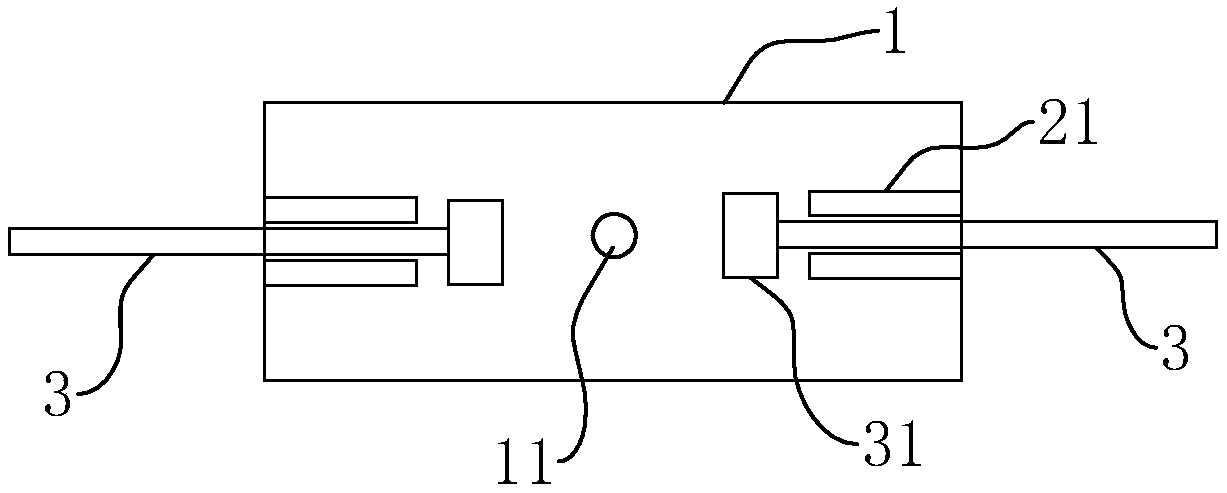

[0065] Such as figure 1 , figure 2 and image 3 As shown, a steel bar connection device and its connection structure, the connection device includes a bottom plate 1, two groups of U-shaped cards 2 vertically fixed on the upper surface of the bottom plate 1; two groups of U-shaped cards 2 are parallel to each other, and each group of U-shaped cards 2 includes two clamping pieces vertically fixed on the upper surface of the bottom plate 1; two connecting steel bars 3 to be connected are fixed with an expanding head 31 at one end close to the connecting device, and the gap between the two clamping pieces is larger than that to be connected. The outer diameter of connecting steel bar 3 is less than the size of enlarging head 31. The bottom plate 1 can be made of steel plate or strip steel, and the clamping part is a clamping plate 21 , and the direction of the clamping plate 21 is parallel to the direction of the connecting steel bar 3 .

[0066] Such as figure 1 As shown,...

Embodiment 2

[0070] The difference from Embodiment 1 is that: Figure 6 and Figure 7 As shown, the clamping plates 21 are arranged obliquely, and the two clamping plates 21 of each set of U-shaped cards 2 form a trumpet shape, and the opening of the horn faces the other set of U-shaped cards 2 . One end surface of the enlarging head 31 facing the pulling out of the connecting device is a circular table surface 32 . The horn opening is adapted to the round table surface 32 . Since the enlarged head 31 has a larger contact area with the clamping plate 21, the force is better.

Embodiment 3

[0072] The difference from Embodiment 1 is that: Figure 8 As shown, a pin hole is provided on the clamping plate 21 , and the clamping pin 4 penetrates into the pin hole to close the opening of the U-shaped clamp 2 . The clamping pin 4 closes the opening of the U-shaped clamp 2, which can prevent the connecting steel bar 3 from slipping out of the opening when subjected to a relatively large pulling force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com