Super-resolution optical imaging method for forming small-hole probe based on double-beam transient trepanning

A pinhole probe and optical imaging technology, applied in the field of super-resolution optical imaging, can solve problems such as sample damage, and achieve the effects of low cost, remarkable imaging effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A super-resolution optical imaging method based on double-beam transient opening to form a pinhole probe, the steps of which include:

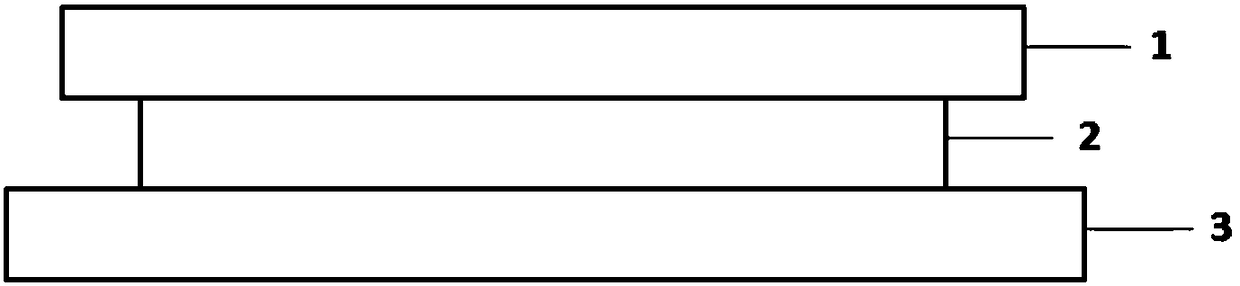

[0039] a) coating a layer of phase-change film material 2 on the cover glass 1 by magnetron sputtering;

[0040] b) The above-mentioned cover glass 1 coated with the phase-change thin film material 2 is closely attached to the surface of the sample 3 to be tested, and the side coated with the film is next to the sample;

[0041] c) placing the cover glass 1 and the sample 3 together on the imaging sample moving stage 8;

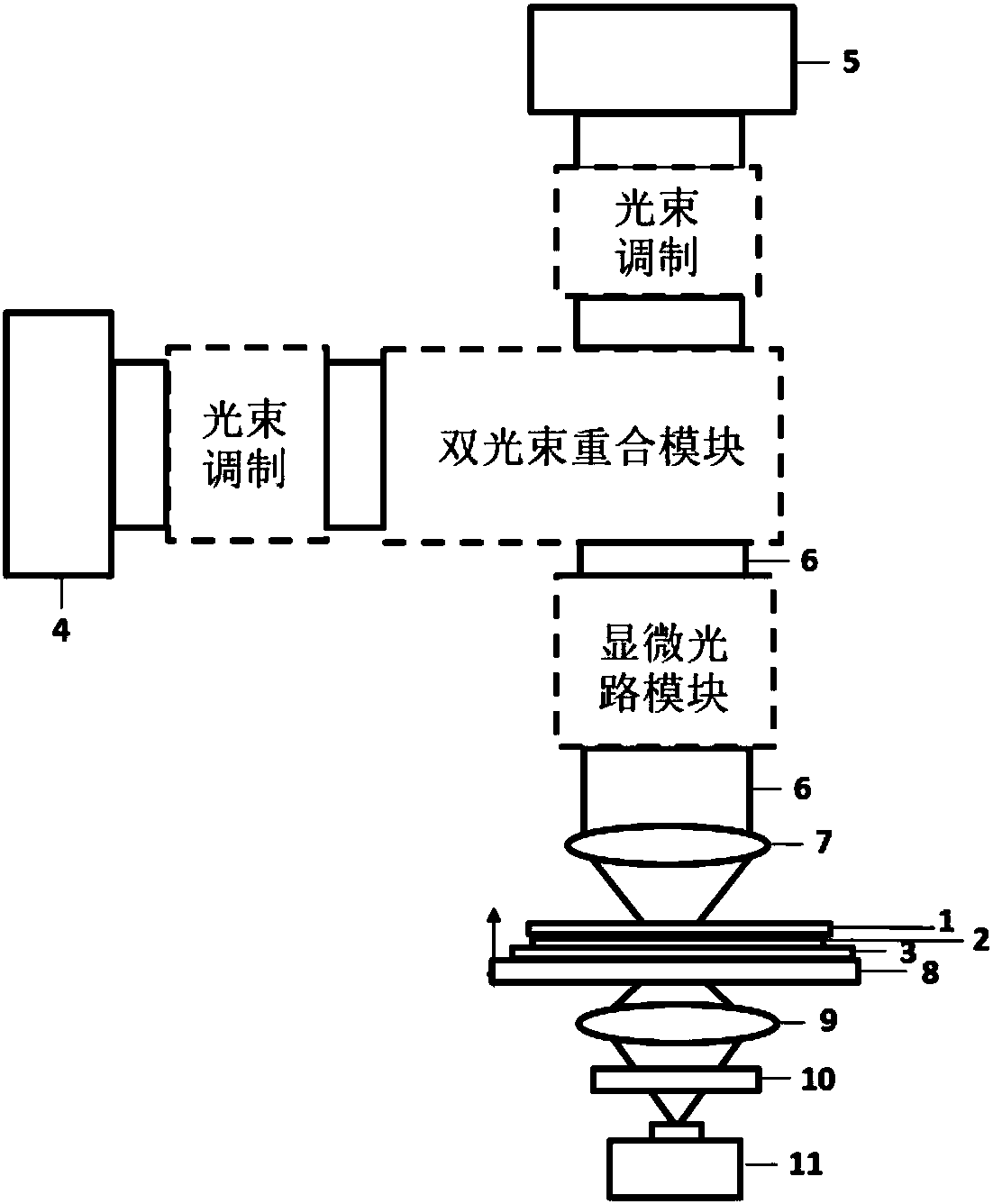

[0042] d) Using a beam of light with a power density less than 2×109 W / m 2 The probe light 5 and a beam of light with the same wavelength have a power density greater than 2×10 9 W / m 2 , the excitation light 4 with a pulse frequency greater than 1Mhz passes through the cover glass 1 at the same time, and irradiates the same area on the sample 3;

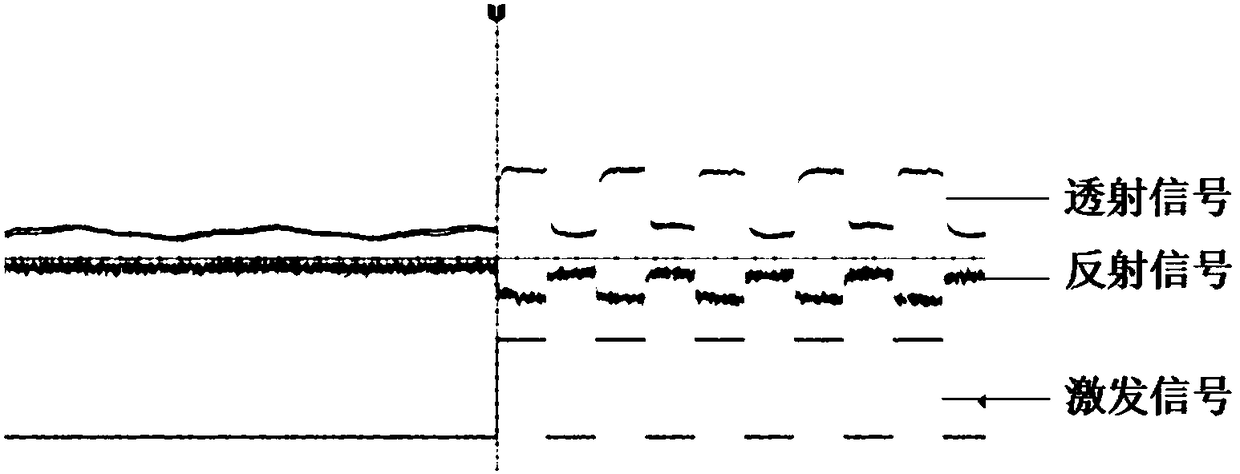

[0043] e) pass the light signal transmitted through the cover glass ...

Embodiment 2

[0050] A super-resolution optical imaging method based on double-beam transient opening to form a pinhole probe, the steps of which include:

[0051] a) coating a layer of phase-change film material 2 on the cover glass 1 by magnetron sputtering;

[0052] b) The above-mentioned cover glass 1 coated with the phase-change thin film material 2 is closely attached to the surface of the sample 3 to be tested, and the side coated with the film is next to the sample;

[0053] c) placing the cover glass 1 and the sample 3 together on the imaging sample moving stage 8;

[0054] d) Using a beam of optical power density less than 2×10 9 W / m 2 The probe light 5 and a beam of light with the same wavelength have a power density greater than 2×10 9 W / m 2 , the excitation light 4 with a pulse frequency greater than 1Mhz irradiates the same area on the sample 3;

[0055] e) pass the light signal transmitted through the cover glass 1 and the sample 3 through a filter 10, and filter out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com