Near-field dynamics modeling method for composite materials in thermal conduction problem

A technology of dynamic modeling and composite materials, which is applied in the field of heat transfer system design and manufacture, can solve the problems of heavy workload and low calculation precision, and achieve the effects of high precision, algorithm optimization and good grid adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Taking the heat conduction of the front end material of a blunt cone aircraft as an example, the method of the present invention is used to carry out peridynamic modeling. Among them, the front end material of the blunt cone aircraft contains three components: air, heat-resistant coating and internal aluminum alloy material.

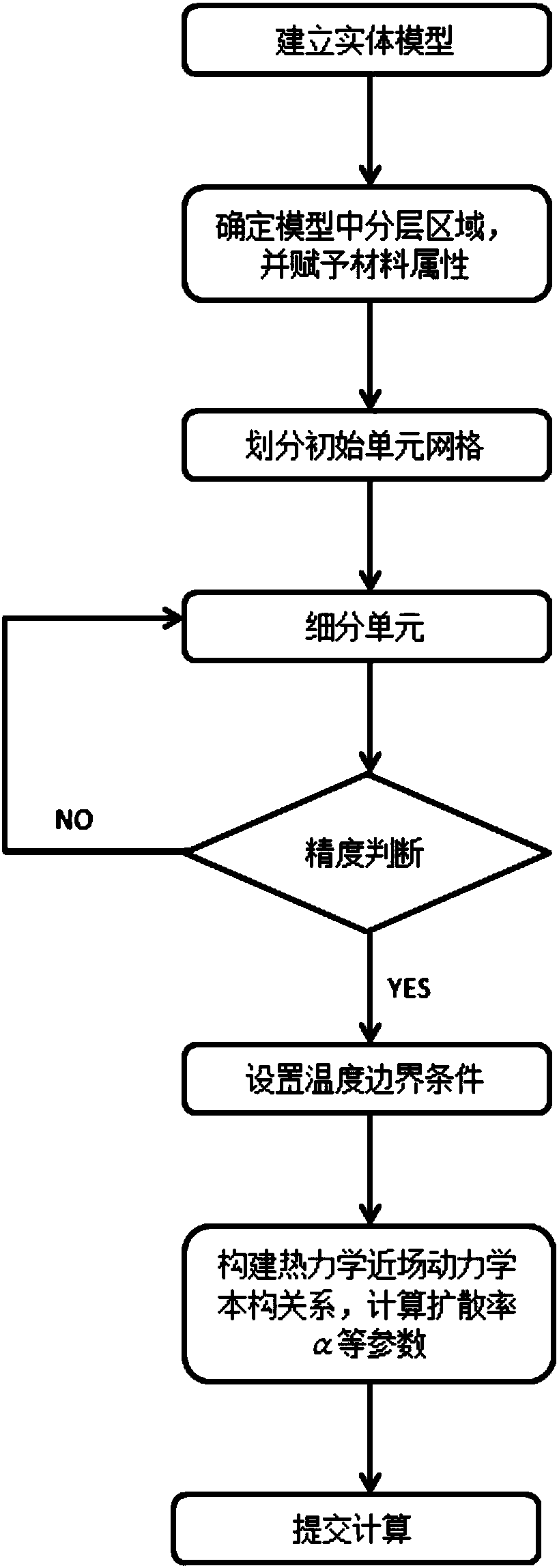

[0044] The main steps of the modeling method are as follows:

[0045] 1) Set up a solid model, the outer contour size of the solid model is the same as the front end of the blunt cone aircraft;

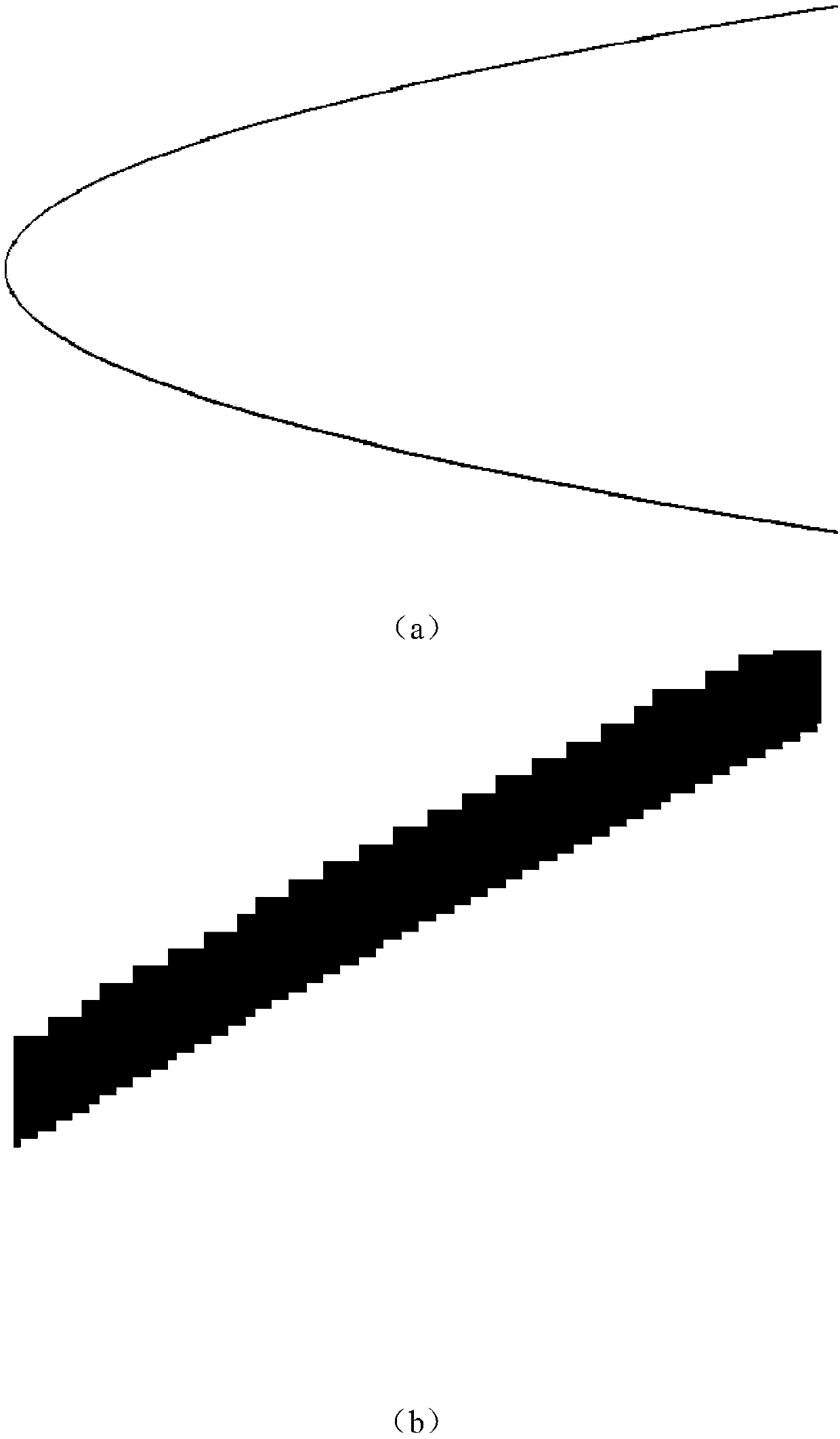

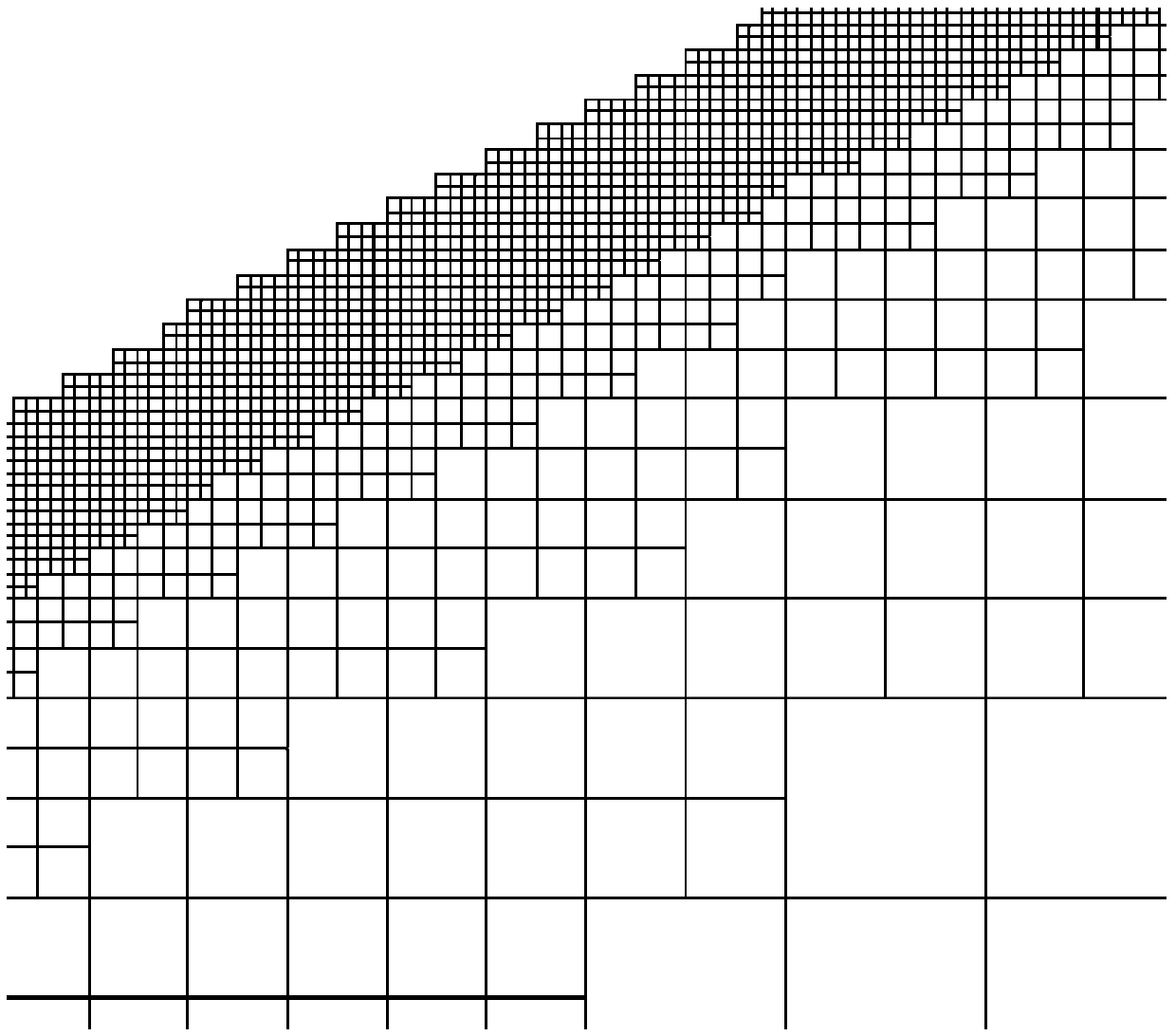

[0046] 2) According to the distribution law of each component in the actual material, the solid model is divided, the position of the layered area of each material in the model is determined, and the corresponding material properties are assigned to each area, and the interface of each component of the composite material is obtained at the same time, such as figure 2 ,in figure 2 (a) an overview of the entire solid model; figure 2 (b) is the boundar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com