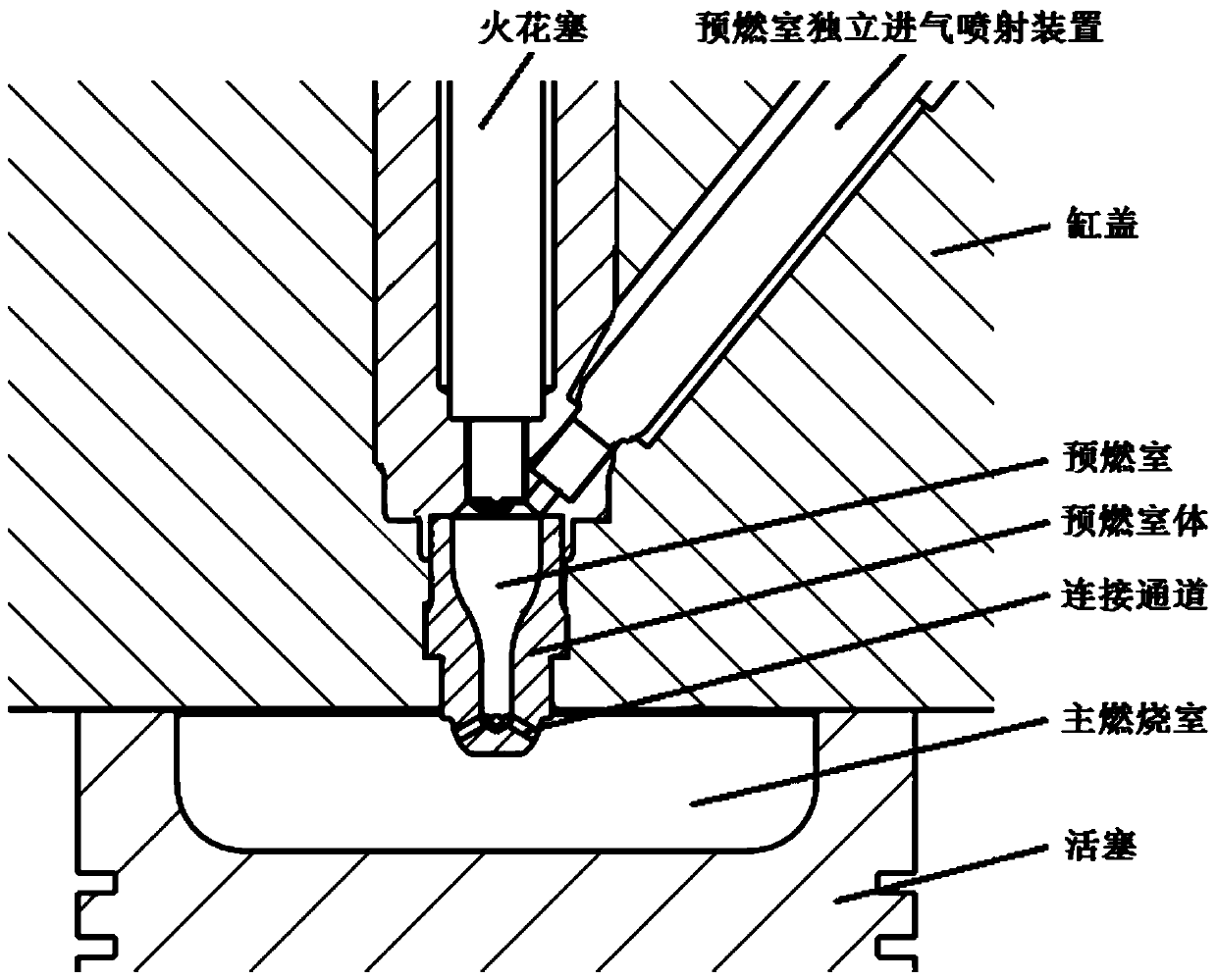

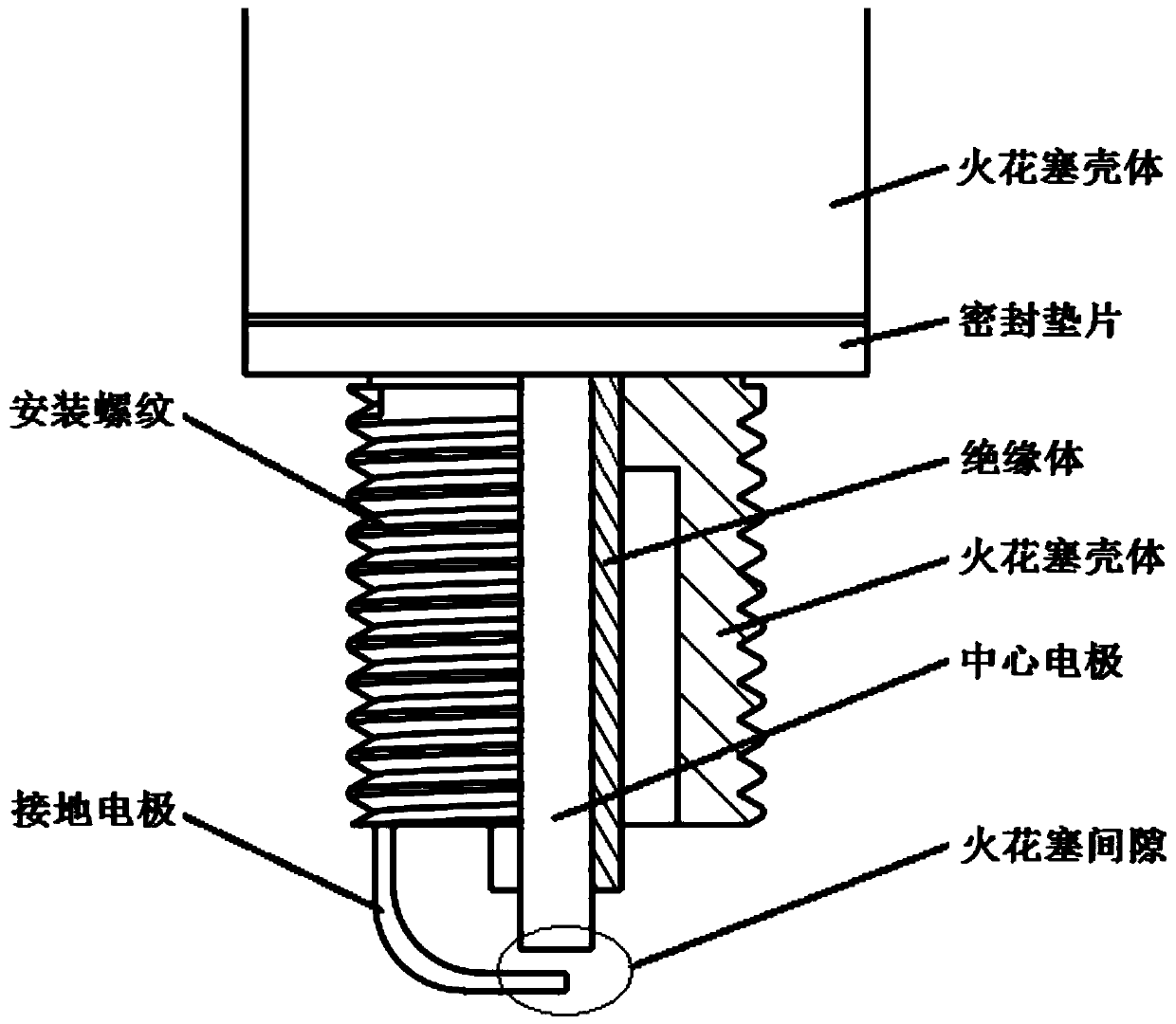

A pre-combustion chamber ignition structure, system and working method thereof

A pre-combustion chamber and spark plug technology, applied in the field of pre-combustion chamber ignition structure, can solve the problems of reducing the total amount of mixture, high emissions, weak intensity of high-energy jets in the pre-combustion chamber, etc., so as to reduce the working cycle fluctuation rate, reduce HC and Effect of CO emission and shortening of flame propagation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

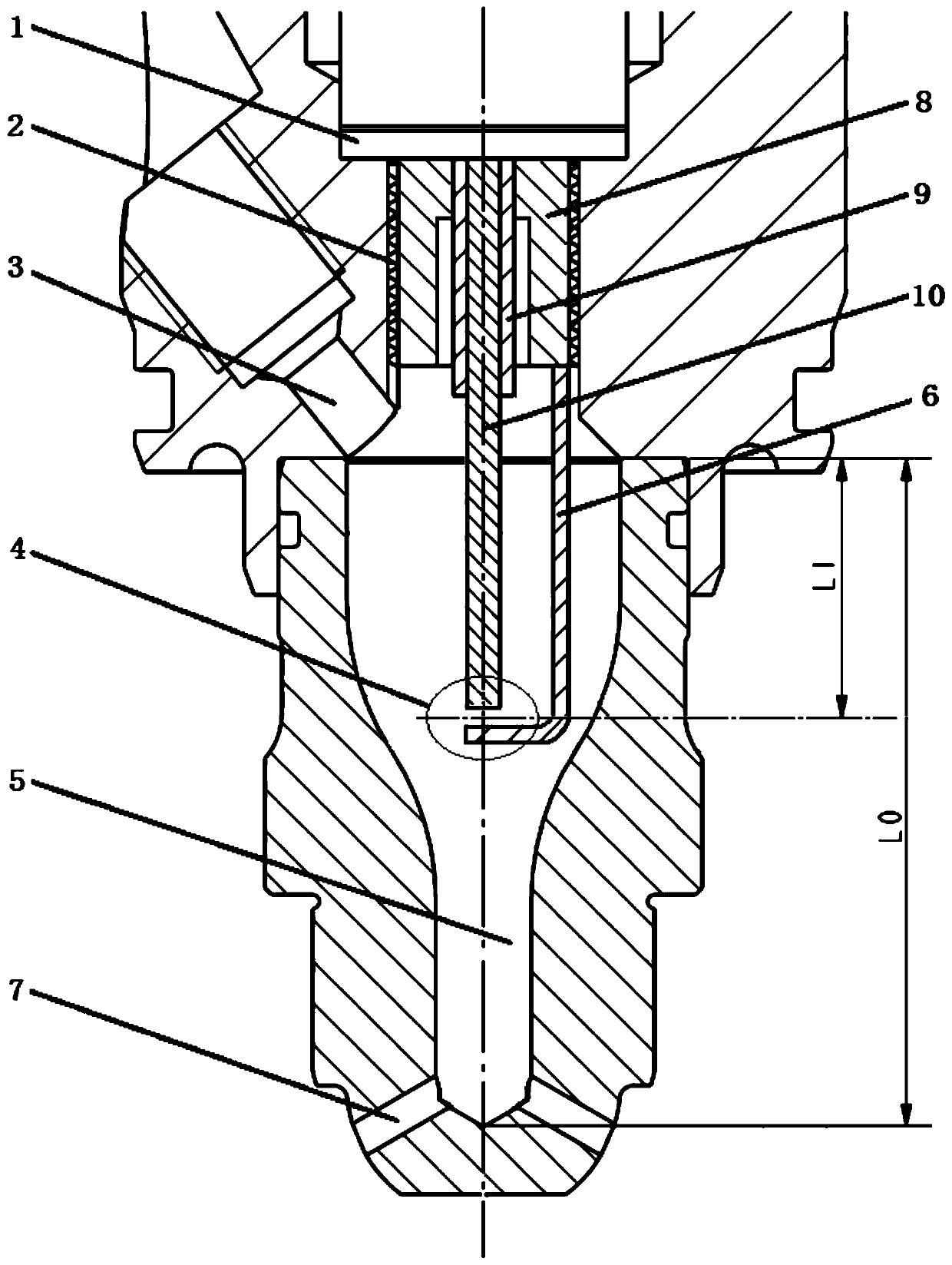

[0041] AVL FIRE is a professional engine performance simulation software, which can accurately simulate the flow and combustion process in the engine cylinder. Using AVL FIRE software, the simulation comparison analysis was carried out on the traditional pre-combustion chamber ignition structure (case1) with the spark plug gap placed on the top of the pre-combustion chamber and the pre-combustion chamber ignition structure (case2) with the spark plug gap moved down in the patent of the present invention. Figure 5(a)-Figure 5(c) and Figure 6(a)-Figure 6(c) It is the cloud map of the flame surface density in the pre-combustion chamber after ignition, which characterizes the flame propagation process in the pre-combustion chamber after the two pre-chamber structures are ignited. In case1, such as Figure 5(a)-Figure 5(c) As shown, after the upper part of the pre-chamber is ignited, the flame first spreads on the top of the pre-chamber, and then spreads downward. Under the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com