Green tea processing technology

A processing technology and green tea technology, applied in the field of green tea processing technology, can solve problems such as pesticide residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of processing technology of green tea, comprises the following steps:

[0024] Step 1. Picking: picking tea leaves with one bud and one leaf and one bud and two leaves as raw materials;

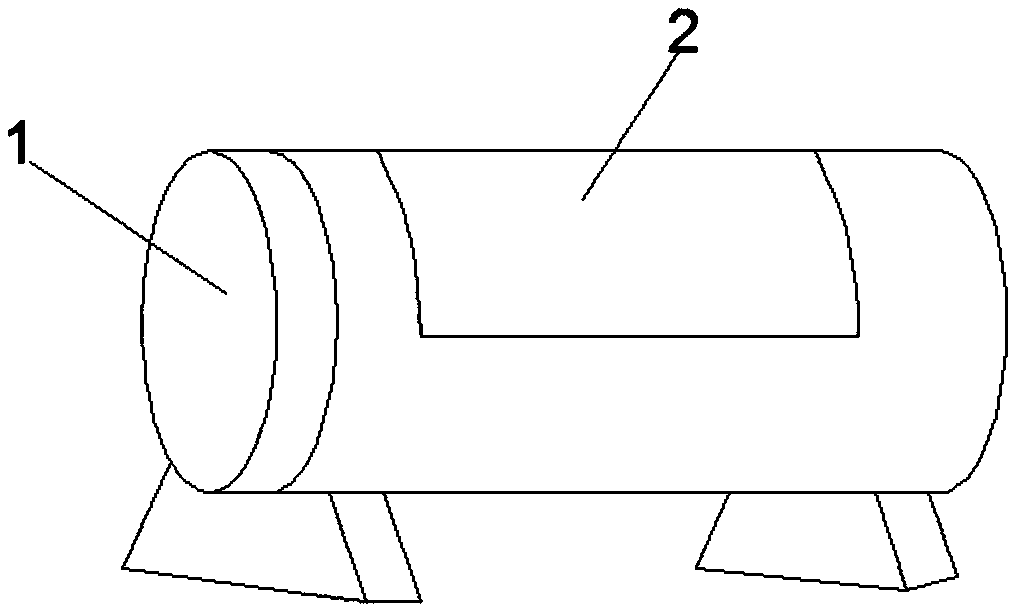

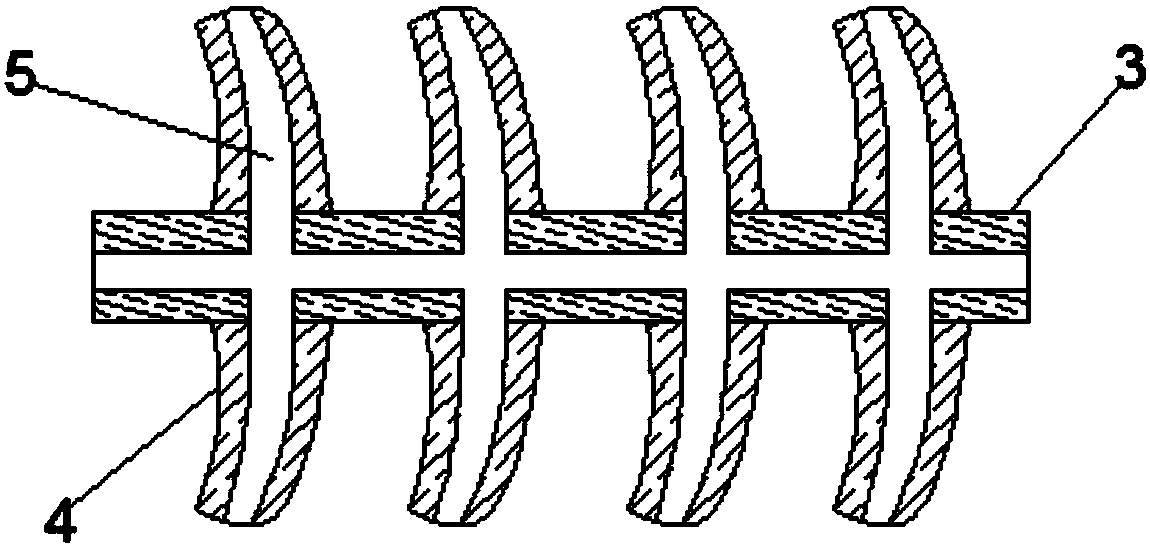

[0025] Step 2. Pesticide treatment: Clean the tea leaves picked in step 1 in the cleaning cylinder, the inner wall of the cleaning cylinder is provided with a titanium dioxide layer, the cleaning cylinder includes a cylinder body and a cylinder cover 1, and the cylinder cover 1 is rotatably connected with a stirring shaft 3, and the stirring The shaft 3 is connected with a motor that drives its rotation. The inside of the stirring shaft 3 is hollow, and the stirring shaft 3 is connected with a plurality of stirring blades 4. The stirring blade 4 is provided with a plurality of air outlet channels 5, and the air outlet channels 5 communicate with the stirring shaft 3. The stirring blade 4 is coated with a titanium dioxide layer, and the inner wall of the cylinder co...

Embodiment 2

[0030] The difference between embodiment 2, embodiment 3 and embodiment 1 is only that the tea leaves are cleaned in the cleaning cylinder in step 2. The cleaning time of embodiment 2 is 25 minutes, and the cleaning time of embodiment 3 is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com