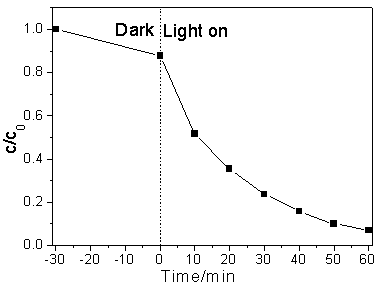

Synthesizing method of net-shaped Ag/Ag3PO4/AgCl (silver/silver phosphate/silver chloride) composite photocatalysis material

A technology of composite photocatalysis and synthesis method, which is applied in the field of synthesis of reticulated Ag/Ag3PO4/AgCl composite photocatalytic materials, and can solve problems such as difficulty in recycling, high loss rate, and complicated reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] The purity of Ag in the silver mesh used is 99.99%, the length and width are 50mm, the thickness is 1mm, the diameter of the silver wire is 0.2mm, and the mesh number is 100 mesh; first, the silver mesh is ultrasonically cleaned with deionized water and acetone Ultrasonic cleaning was carried out at room temperature for 5 minutes. The ultrasonic frequency was 20 kHz and the power was 5 kW. Dry; then put the silver mesh into the mixture of phosphoric acid and hydrochloric acid, soak it at 40°C for 8 minutes, the concentration of phosphoric acid in the mixture is 1mol / L, and the concentration of hydrochloric acid is 0.5mol / L; take out the silver mesh and wash it with deionized water 3 times, and then dried with nitrogen to obtain a network Ag / Ag 3 PO 4 / AgCl composite photocatalytic material; the purity of nitrogen gas used for drying with nitrogen gas is >99%, and the flow rate of nitrogen gas is 1m 3 / min.

example 2

[0022] The purity of Ag in the silver mesh used is 99.99%, the length and width are 100mm, the thickness is 1mm, the diameter of the silver wire is 0.2mm, and the mesh number is 120 mesh; first, the silver mesh is ultrasonically cleaned with deionized water and acetone Ultrasonic cleaning was carried out at room temperature for 5 minutes. The ultrasonic frequency was 30 kHz and the power was 8 kW. Dry; then put the silver mesh into the mixture of phosphoric acid and hydrochloric acid, soak it at 45°C for 7 minutes, the concentration of phosphoric acid in the mixture is 1.5mol / L, and the concentration of hydrochloric acid is 0.5mol / L; take out the silver mesh and wash it with deionized water After washing 3 times and then blowing dry with nitrogen, the net-like Ag / Ag 3 PO 4 / AgCl composite photocatalytic material; the purity of nitrogen gas used for drying with nitrogen gas is >99%, and the flow rate of nitrogen gas is 1m 3 / min.

example 3

[0024] The purity of Ag in the silver mesh used is 99.99%, the length and width are 200mm, the thickness is 1mm, the diameter of the silver wire is 0.3mm, and the mesh number is 120 mesh; first, the silver mesh is ultrasonically cleaned with deionized water and acetone 5min, ultrasonic cleaning was carried out at room temperature, the ultrasonic frequency was 30kHz, and the power was 10kW. Dry; then put the silver mesh into the mixture of phosphoric acid and hydrochloric acid, soak it at 40°C for 10 minutes, the concentration of phosphoric acid in the mixture is 1.5mol / L, and the concentration of hydrochloric acid is 1mol / L; take out the silver mesh and wash it with deionized water 3 times, and then dried with nitrogen to obtain a network Ag / Ag 3 PO 4 / AgCl composite photocatalytic material; the purity of nitrogen gas used for drying with nitrogen gas is >99%, and the flow rate of nitrogen gas is 1m 3 / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com