A laser welding process

A laser welding and process technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of poor laser welding welding effect, and achieve the effect of reducing repeatability requirements, reducing welding difficulty, and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The inventor found that the existing welding technology focuses all the energy on a very small point. In the actual seam welding welding production, because under the same welding pool effect conditions, the molten pool area on the product butt joint determines the welding capacity. Therefore, in the actual production operation, the movement trajectory of the laser focus and the overlapping precision of the product joint seam require high accuracy, which increases the difficulty of welding , and it is difficult to guarantee the welding quality.

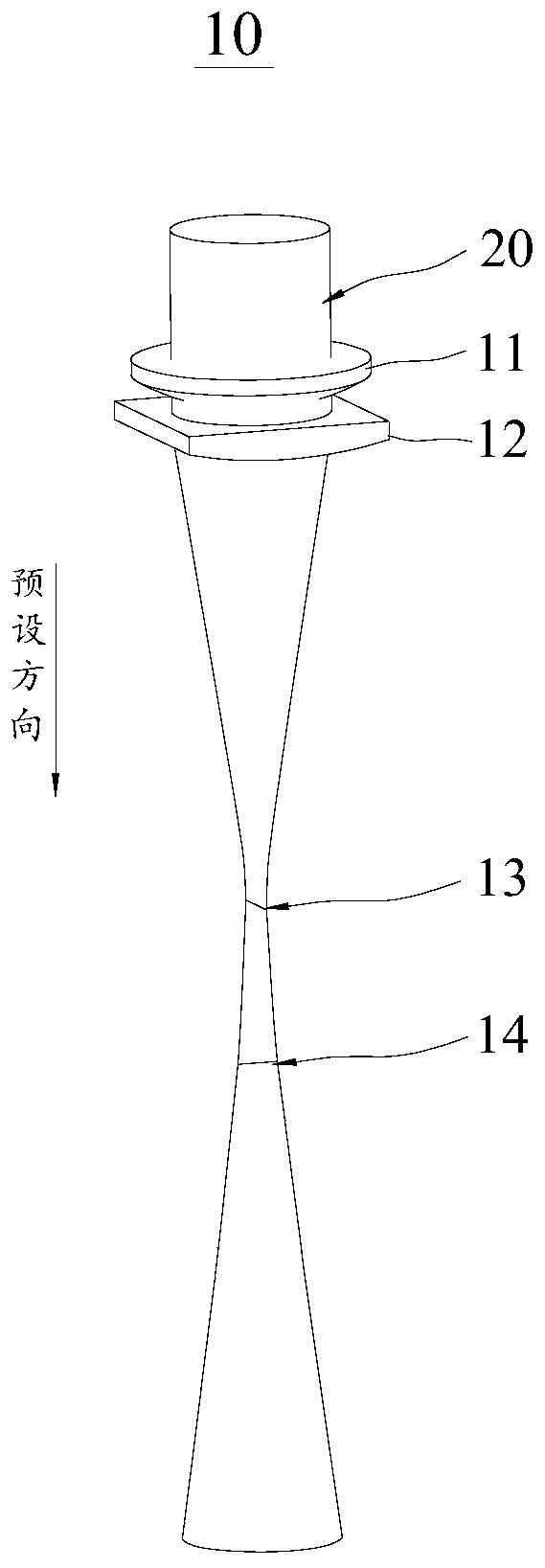

[0044] Based on this, the present embodiment provides a laser welding process, which uses the laser beam 20 to pass through the lens assembly 10 of the welding lens, which can improve the welding quality.

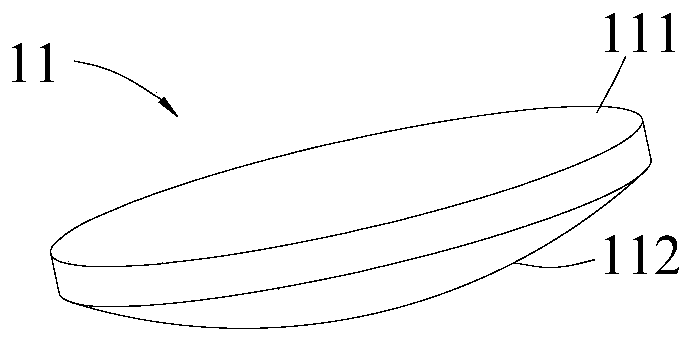

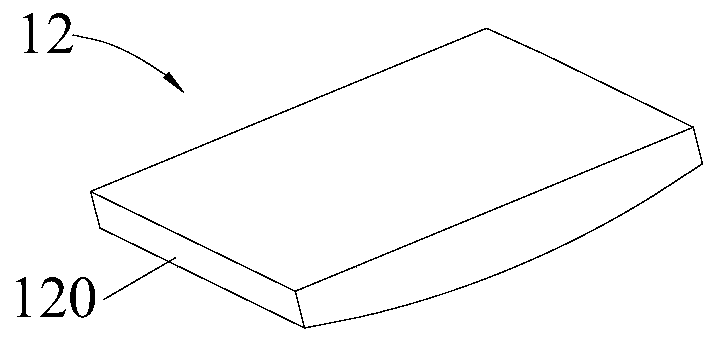

[0045] Specifically, please refer to figure 1 , using the laser beam 20 to pass through the lens assembly 10 in the laser welding lens to form a molten pool on the weldment with two focused spots formed in a preset directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com