Building decorative sheet cutting machine convenient to adjust

A technology for plate cutting machinery and architectural decoration, applied in sawing equipment, manufacturing tools, wood processing appliances, etc., can solve the problems of unfavorable equipment use, inconvenient movement, limited cutting range, etc., to achieve high work stability and improve applicability , good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

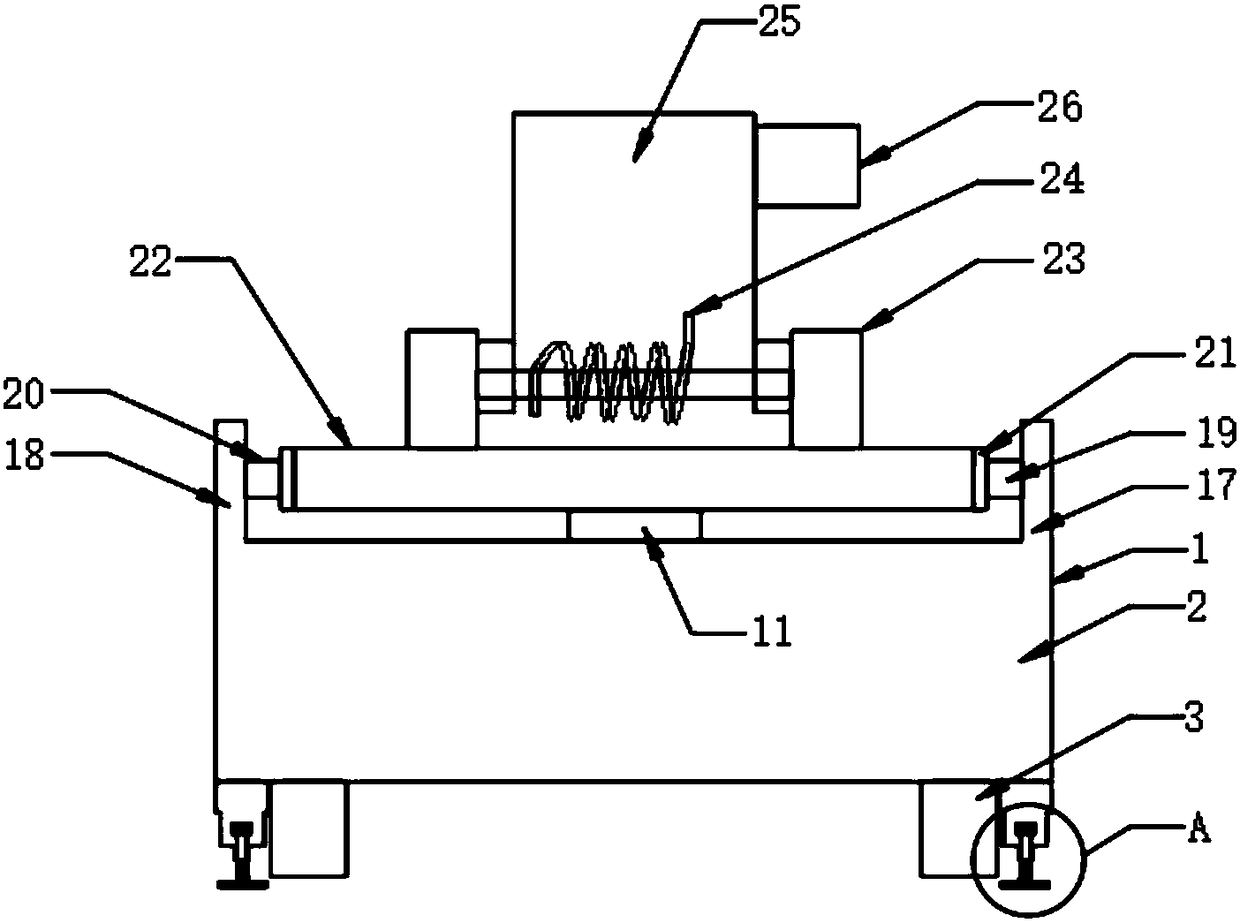

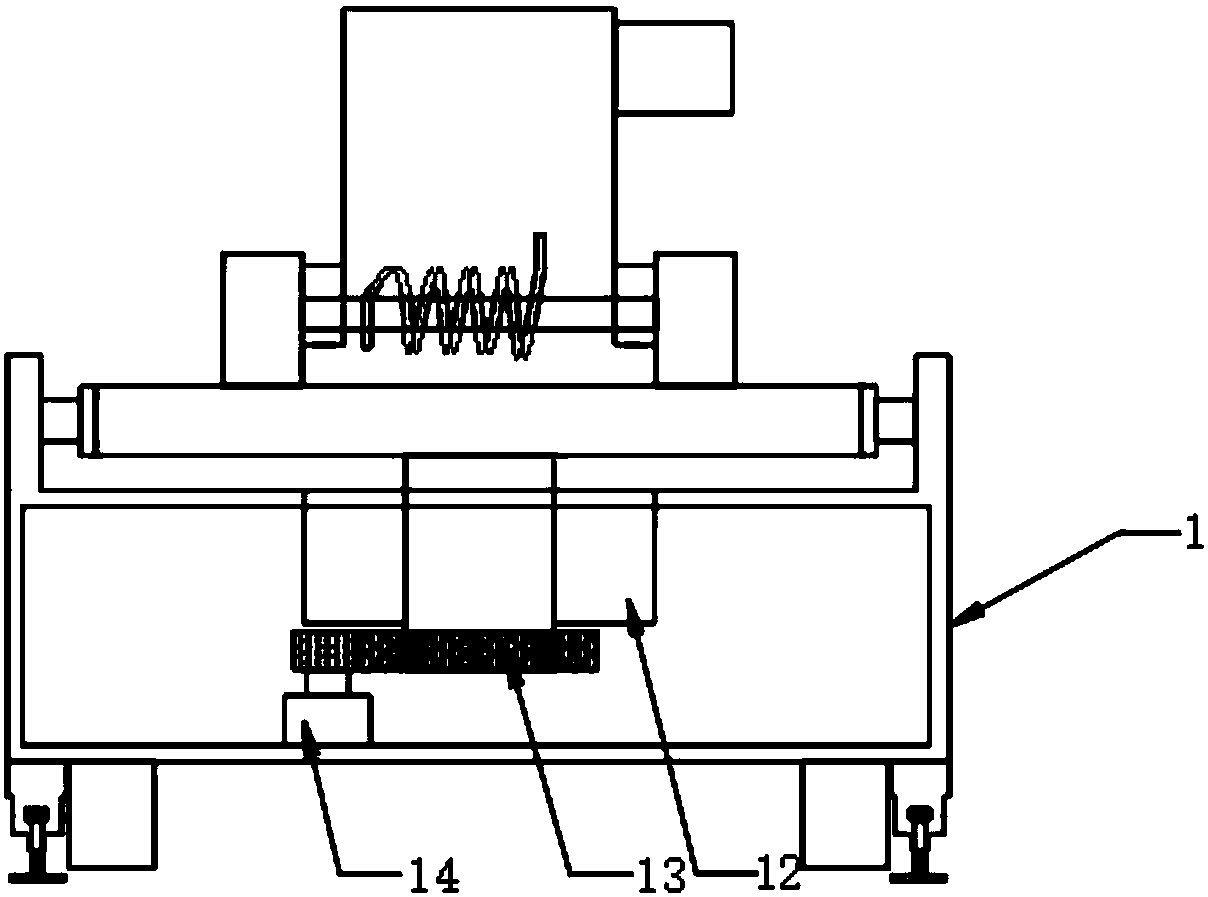

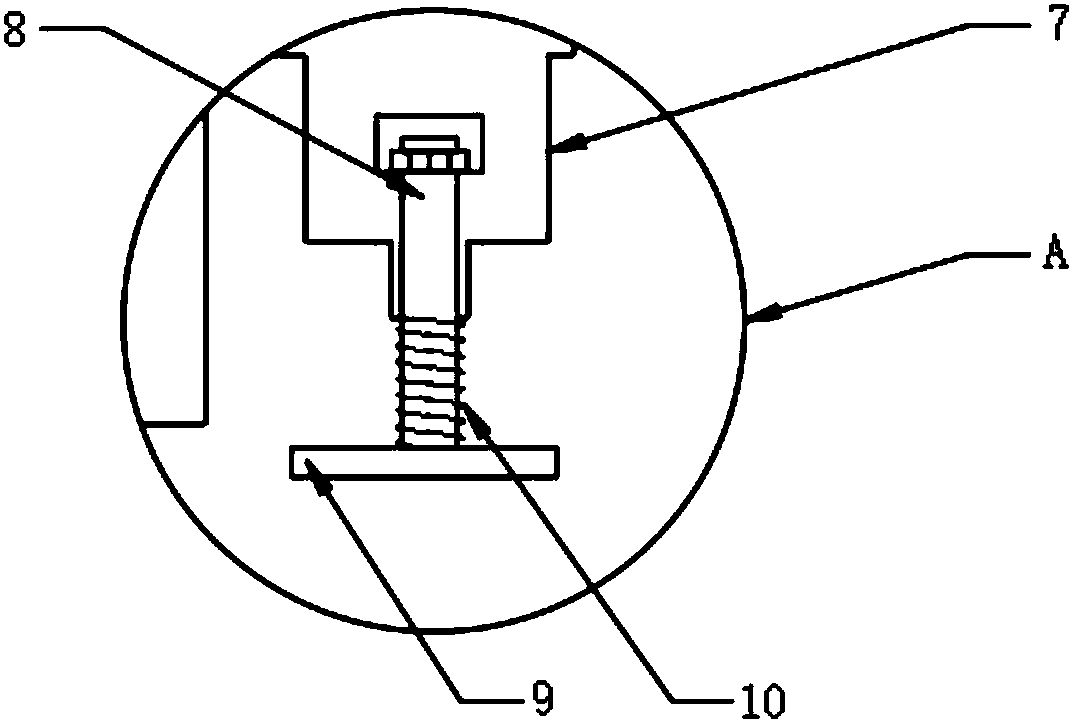

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0023] see Figure 1-6 , the present invention provides a technical solution: a cutting machine for building decorative panels that is easy to adjust, including a cutting machine body 1, a base 2, a housing 3, a groove 4, a first hydraulic cylinder 5, a pulley 6, a connecting block 7, The first support rod 8, the support plate 9, the damping spring 10, the rotating rod 11, the bearing 12, the driven gear 13, the servo motor 14, the motor shaft 15, the driving gear 16, the first support 17, the second support 18, the first Second hydraulic cylinder 19, third hydraulic cylinder 20, fastening block 21, support seat 22, second support rod 23, return force spring 24, mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com