Fluorescent tracing-type scale inhibitor and preparation method and application thereof

A technology of fluorescent tracer and scale inhibitor, applied in the field of scale inhibitor, can solve the problems of no tracer detection effect, difficulty in inhibiting calcium phosphate dispersing iron oxide, difficulty in detecting scale inhibitor quickly and conveniently, etc. On-line monitoring and automatic drug delivery function, the effect of improving corrosion inhibition performance, excellent calcium phosphate inhibition and dispersing iron oxide performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

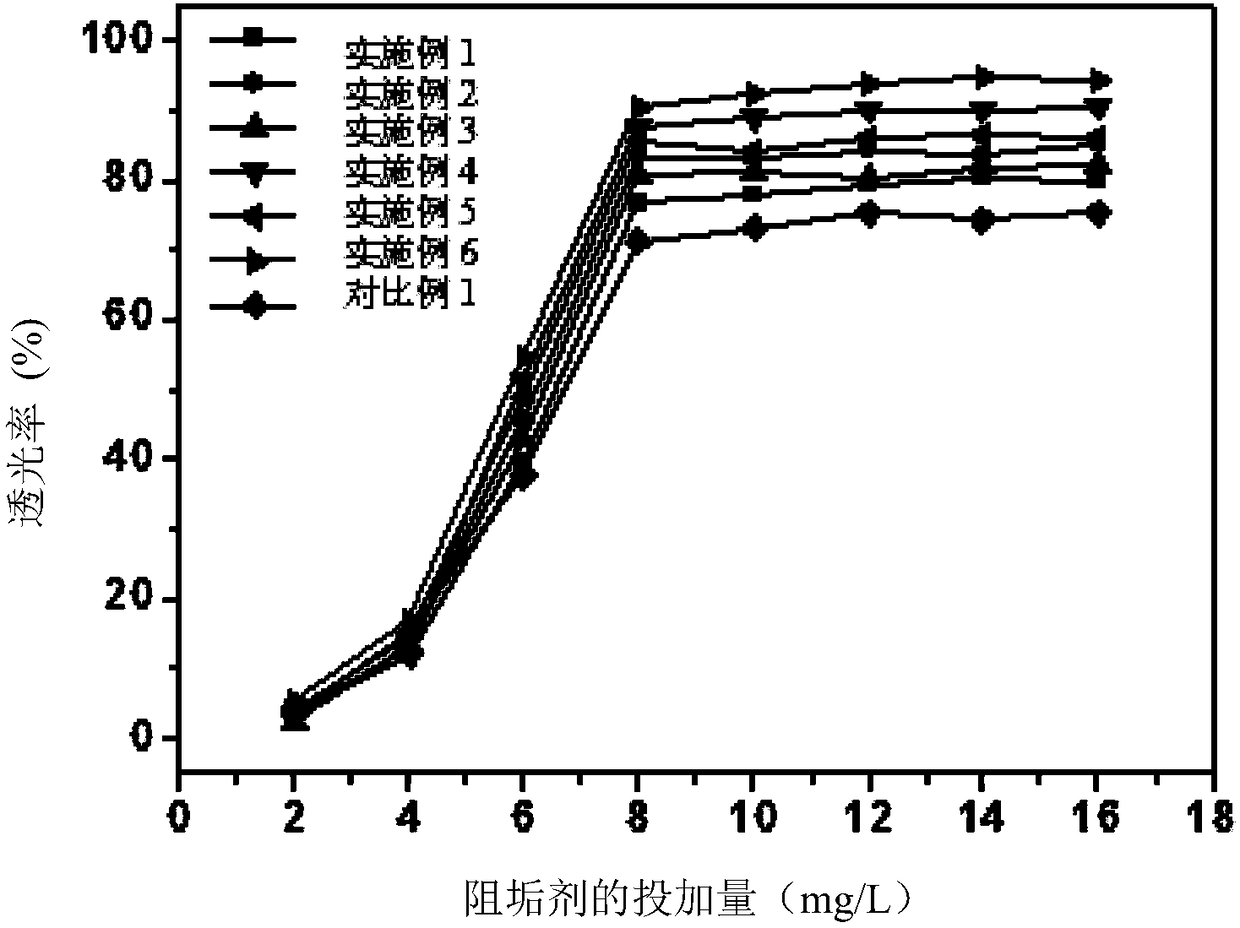

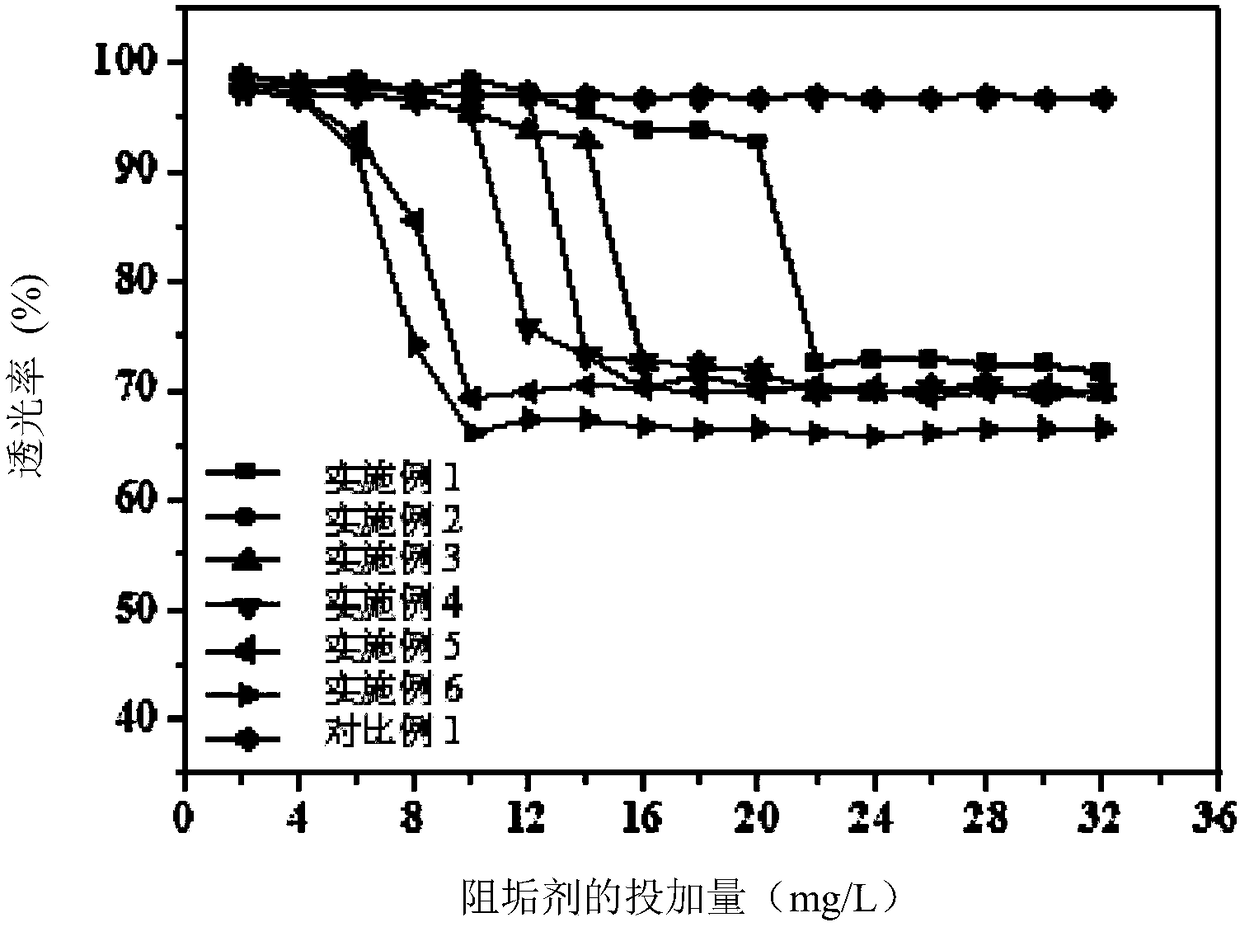

Examples

Embodiment 1

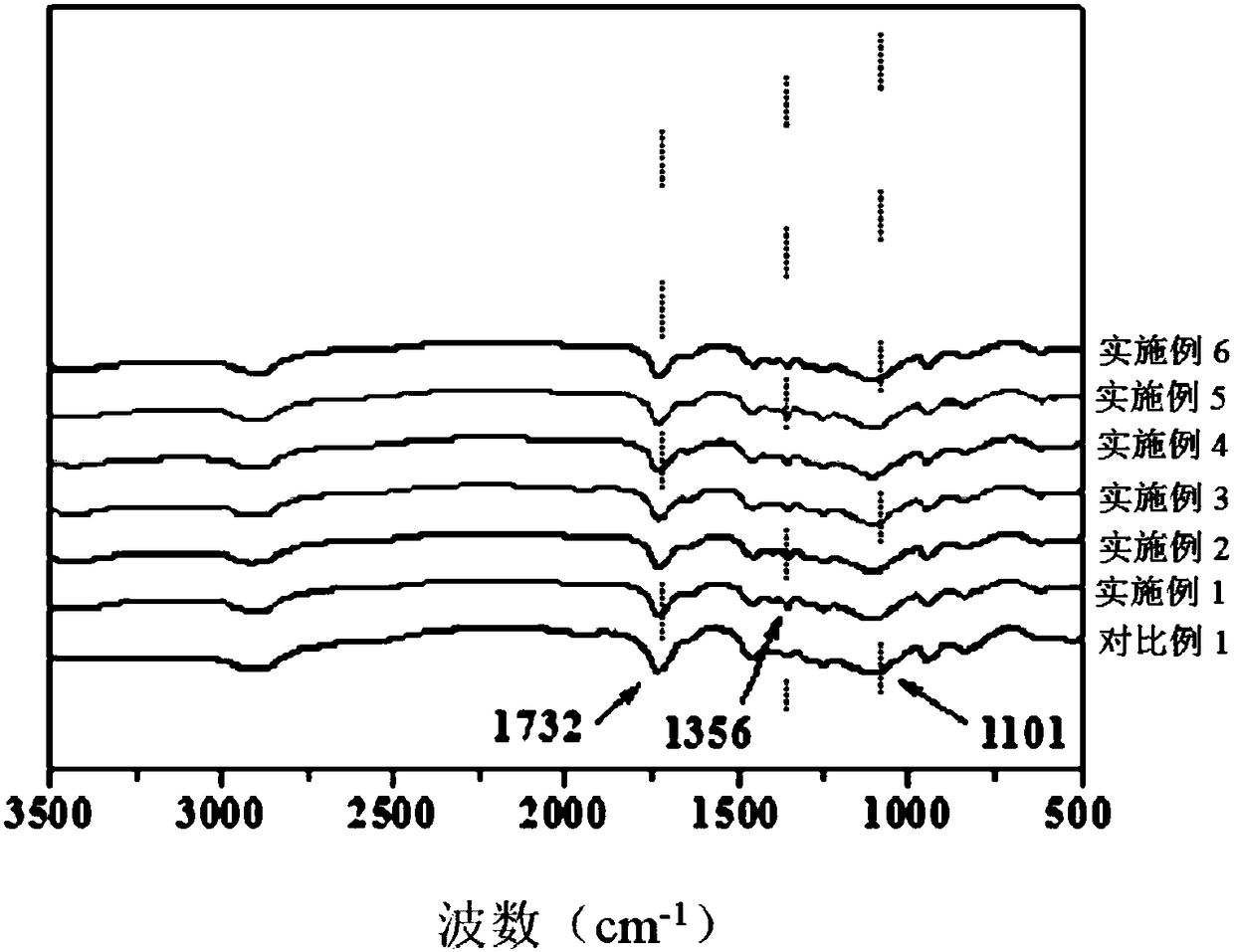

[0039] Weigh 4-bromo-1,8-naphthalene dicarboxylic anhydride and dissolve it in absolute ethanol. Under the condition of stirring, slowly heat the mixed solution to 60°C, then add ethanolamine dropwise, and reflux for 3h ( The mass ratio of 4-bromo-1,8-naphthalene dicarboxylic anhydride, ethanolamine, and ethanol is 1:0.3:40, and the magneton speed is 80r / min). After the reaction, the product was filtered while it was hot, the filtrate was cooled, and filtered with suction, the obtained filter cake was recrystallized, and a light yellow solid product was obtained after drying.

[0040]Add the light yellow solid product obtained in the previous step into ethylene glycol methyl ether, stir while heating to fully dissolve, stir to form a uniform mixed solution, then raise the temperature to 80°C, then add N-methylpiperazine dropwise, within 0.5h Reflux for 5 hours after dropping (the mass ratio of light yellow solid product, N-methylpiperazine, and ethylene glycol methyl ether obt...

Embodiment 2

[0047] Weigh 4-bromo-1,8-naphthalene dicarboxylic anhydride and dissolve it in absolute ethanol. While stirring, heat the mixed solution slowly to 60°C, then add ethanolamine solution dropwise, and reflux for 3 hours after dropping within 0.5h (The mass ratio of 4-bromo-1,8-naphthalic anhydride, ethanolamine, and ethanol is 1:0.6:60, and the magneton speed is 80r / min). After the reaction, the product was filtered while it was hot, the filtrate was cooled, and filtered with suction, the obtained filter cake was recrystallized, and a light yellow solid product was obtained after drying.

[0048] Add the light yellow solid product obtained in the previous step into ethylene glycol methyl ether, stir while heating to fully dissolve, stir to form a uniform mixed solution, then raise the temperature to 80°C, then add N-methylpiperazine dropwise, within 0.5h Reflux for 5 hours after dropping (the mass ratio of light yellow solid product, N-methylpiperazine, and ethylene glycol methyl...

Embodiment 3

[0055] Weigh 4-bromo-1,8-naphthalene dicarboxylic anhydride and dissolve it in absolute ethanol. Under the condition of stirring, slowly heat the mixed solution to 60°C, then add ethanolamine dropwise, and reflux for 3h ( The mass ratio of 4-bromo-1,8-naphthalic anhydride, ethanolamine, and ethanol is 1:0.5:70, and the magneton speed is 80r / min). After the reaction, the product was filtered while it was hot, the filtrate was cooled, and filtered with suction, the obtained filter cake was recrystallized, and a light yellow solid product was obtained after drying.

[0056] Add the light yellow solid product obtained in the previous step into ethylene glycol methyl ether, stir while heating to fully dissolve, stir to form a uniform mixed solution, then raise the temperature to 80°C, then add N-methylpiperazine dropwise, within 0.5h Reflux for 5 hours after dropping (the mass ratio of light yellow solid product, N-methylpiperazine, and ethylene glycol methyl ether obtained in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com