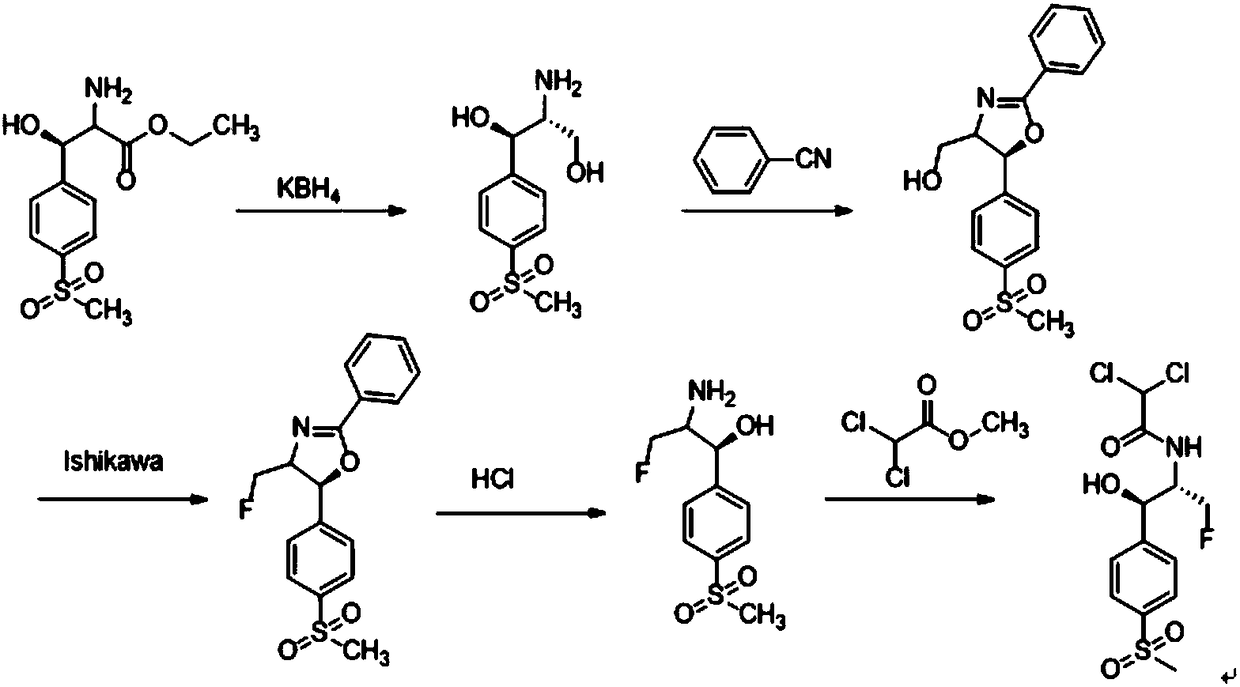

Preparation method of florfenicol intermediate

A technology of florfenicol and intermediates, which is applied in the field of preparation of florfenicol intermediates, can solve the problems of many by-products, low yield and high atomic economic cost, and achieves reduction of by-product generation and improved yield , the effect of reducing the cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a preparation method of florfenicol intermediate. The preparation method of the florfenicol intermediate includes the following steps:

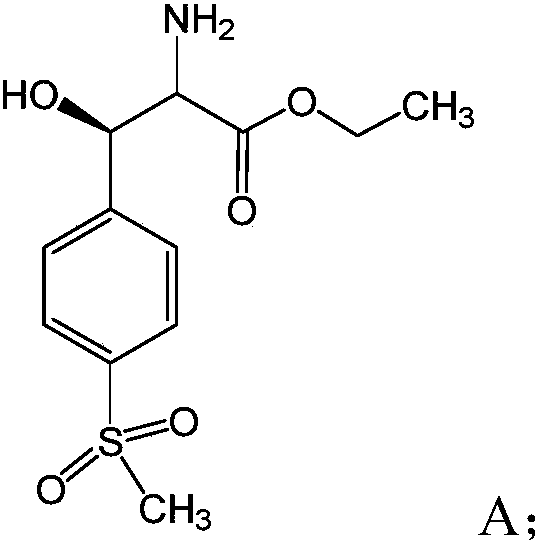

[0015] S01: Provide compound A with the following structural formula:

[0016]

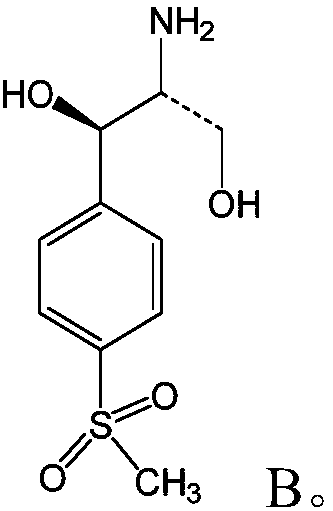

[0017] S02: The compound A is subjected to an oxidation-reduction reaction in a solvent containing an acridine salt photocatalyst and a reducing agent to generate compound B of the following structural formula:

[0018]

[0019] Specifically, the compound A in the step S01 is named D-(-)-threo-[p-(methylsulfonyl)phenyl]serine ethyl ester, which can be prepared according to conventional methods.

[0020] In the light reaction in the step S02, the compound A undergoes an oxidation-reduction reaction with the reducing agent under the action of light and the catalysis of the acridine salt photocatalyst to produce the compound B as a product. The chemical reaction formula of the redox reaction is as follows:

[0021]

[0022] Wherein, the acridin...

Embodiment 1

[0034] This embodiment provides a preparation method of florfenicol intermediate. The synthetic method of the florfenicol intermediate:

[0035] The compound A mentioned above is also D-(-)-threo-[p-(methylsulfonyl)phenyl]serine ethyl ester, the above-mentioned acridine salt visible light catalyst, diisopropylethyl The amine was added to anhydrous dichloroethane, and then the reaction environment was replaced with nitrogen three times, irradiated with a blue LED, and the reaction time was 20h. After the reaction, the filtrate was spin-dried and separated by column chromatography to obtain the target product as a colorless white solid with a yield of 65%.

[0036] Wherein, the compound A, acridine salt, diisopropylethylamine and anhydrous dichloroethane are added in the following proportions: for every 2mL of anhydrous dichloroethane, add 0.2mmol, 1.0eq of the Compound A, 0.2mmol, 1.0eq of diisopropylethylamine, 0.02mmol, 0.1eq of acridine salt.

[0037] NMR and mass spectrometry o...

Embodiment 2

[0040] This embodiment provides a preparation method of florfenicol intermediate. The synthetic method of the florfenicol intermediate:

[0041] The compound A mentioned above is also D-(-)-threo-[p-(methylsulfonyl)phenyl]serine ethyl ester, the above-mentioned acridine salt visible light catalyst, diisopropylethyl The amine was added to anhydrous dichloroethane, and then the reaction environment was replaced with nitrogen three times, irradiated with a blue LED, and the reaction time was 20h. After the completion of the reaction, the filtrate was spin-dried and separated by column chromatography to obtain the target product as a colorless white solid with a yield of 95%.

[0042] Wherein, the compound A, acridine salt, diisopropylethylamine and anhydrous dichloroethane are added in the following proportions: for every 2mL of anhydrous dichloroethane, add 0.2mmol, 1.0eq of the Compound A, 0.4mmol, 2.0eq of diisopropylethylamine, 0.02mmol, 0.1eq of acridine salt.

[0043] NMR and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com