Atomic oxygen protective coating with physical damage spontaneous repairing function and preparation method thereof

A protective coating, atomic oxygen technology, applied in the coating and other directions, can solve the problems of mechanical property degradation and function loss of protective materials, and achieve the effect of good protective effect, strong anti-peeling ability and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

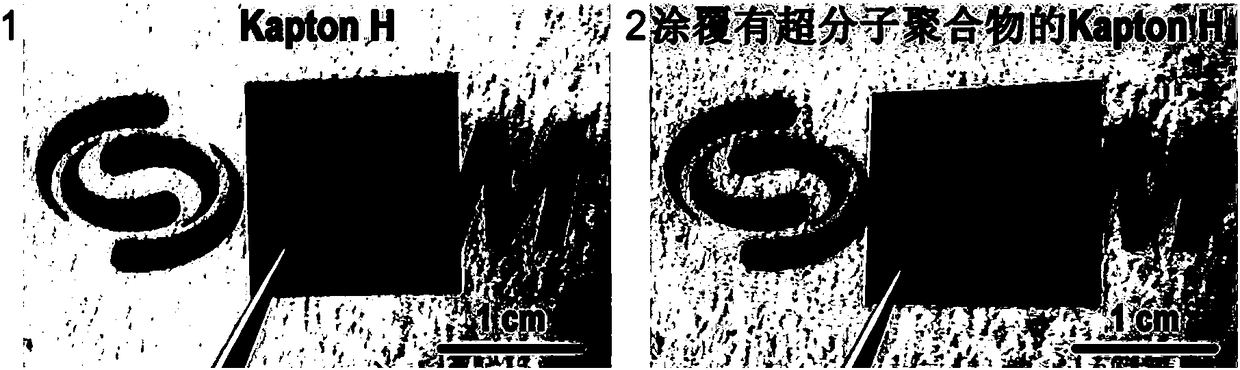

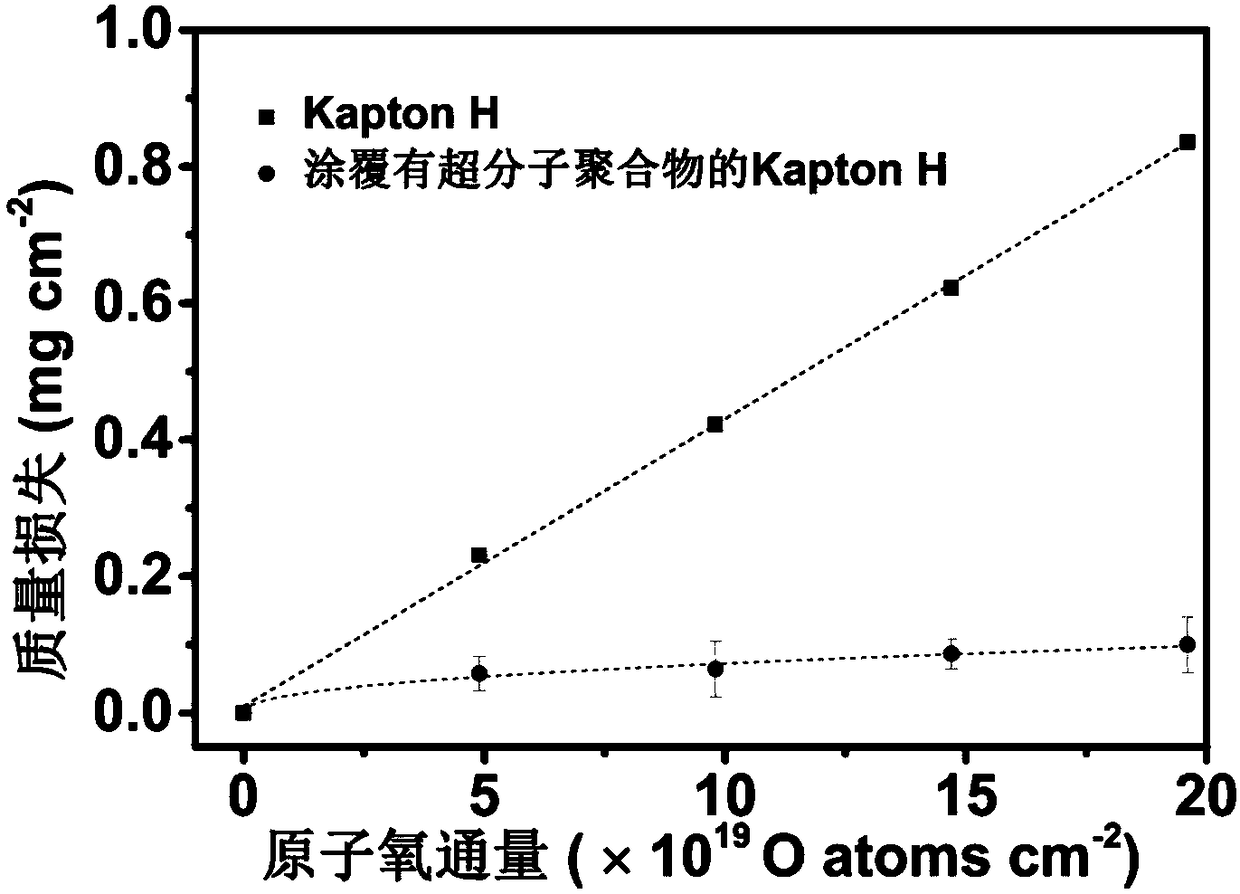

[0025] Embodiment 1: the polyimide film (hereinafter referred to as Kapton HN film) that DuPont produces is the brand that is the polyimide film (hereinafter referred to as Kapton HN film) surface and prepares the supramolecular polymer protective coating with ureido-derived silica nanoparticles as building blocks layer.

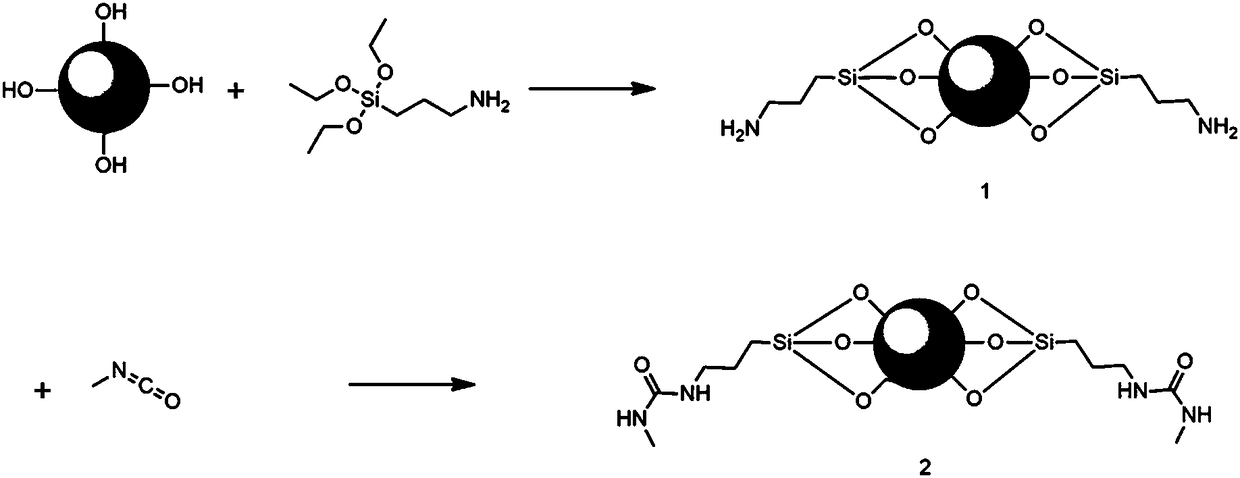

[0026] 1) Preparation of supramolecular polymers. Such as figure 1 The given reaction route, ultrasonic dispersion of silica nanoparticles (2g) with a particle size of 20nm in 500mL of absolute ethanol, slowly added 3-aminopropyltriethoxysilane (1g, 4.5mmol) under vigorous stirring , reacted at 50°C for 24h, centrifuged and washed three times with absolute ethanol and collected to obtain amino-derivatized silica nanoparticles (2.38g).

[0027]The obtained amino-derivatized silica nanoparticles (1 g) were ultrasonically dispersed in 1 L of dry acetone, and methyl isocyanate (0.26 g, 3.6 mmol) was added under stirring, and reacted at 50 °C for 6 h, with The...

Embodiment 2

[0031] Embodiment 2: on the surface of the polyimide film of Kapton HN produced by DuPont, the supramolecular polymer protective coating with amino and carboxyl derivatized polysilsesquioxane as the building block is prepared respectively

[0032] 1) Preparation of supramolecular polymers. Dissolve vinyl polysilsesquioxane (1g, 1.6mmol) in 50mL tetrahydrofuran, add β-mercaptoethylamine (0.98g, 12.8mmol) and stir at room temperature for 10min under the irradiation of a 10w ultraviolet lamp, distill off the solvent to obtain Amino derivatized polysilsesquioxane (1.98 g, 1.6 mmol). The prepared amino-derived polysilsesquioxane was dissolved in dilute hydrochloric acid with a pH value of 5, so that the amino groups on the surface were ionized and positively charged, and the concentration was 5 wt%.

[0033] The obtained amino-derived polysilsesquioxane (0.99g, 0.8mmol) was dissolved in dry tetrahydrofuran, and maleic anhydride (0.63g, 7.7mmol) was added under stirring, and reacte...

Embodiment 3

[0037] Embodiment 3: On the surface of the poly-p-phenylene terephthalamide fiber of Kevlar brand produced by DuPont, alternately deposit supramolecular polymer protection with polysilsesquioxane derived from amino and carboxyl groups as building blocks. coating.

[0038] 1) Preparation of building blocks. Octavinyl polysilsesquioxane (1g, 1.6mmol) was dissolved in 50mL of tetrahydrofuran, and β-mercaptoethylamine (0.98g, 12.8mmol) was added, stirred at room temperature under a 10w ultraviolet lamp for 10min, and the solvent was distilled off to obtain amino Derivatized polysilsesquioxane (1.98 g, 1.6 mmol). The prepared amino-derived polysilsesquioxane was dissolved in dilute hydrochloric acid with a pH value of 5, so that the amino groups on the surface were ionized and positively charged, with a concentration of 2 wt%.

[0039] The obtained amino-derived polysilsesquioxane (0.99g, 0.8mmol) was dissolved in dry tetrahydrofuran, and maleic anhydride (0.63g, 7.7mmol) was add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com