Resin graphene composite material, preparation method and application thereof

A composite material and graphene technology, applied in anti-corrosion coatings, conductive coatings, conductive/anti-static filament manufacturing, etc., can solve the difficulty of combining thermoplastic resins with graphene materials, poor electrical conductivity of resins, and difficulties with graphene materials, etc. problem, to achieve the effect of good thermal conductivity, good electrical conductivity, and good commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

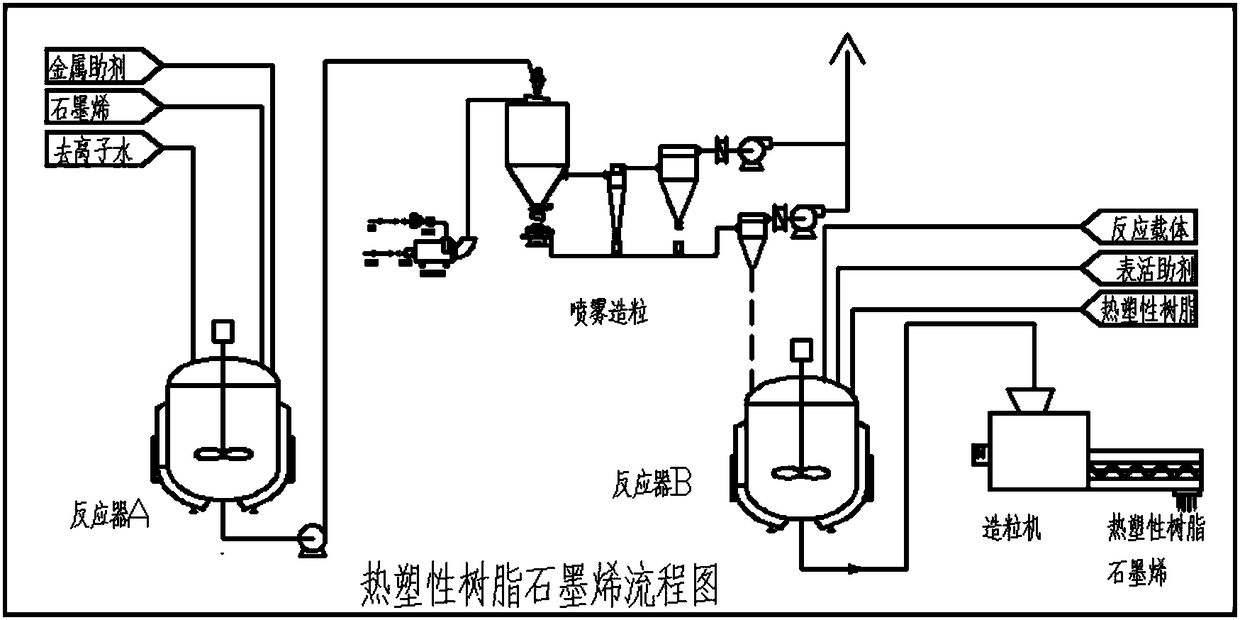

[0033] figure 1 Process flow chart of the preparation method of the resin-graphene composite material provided by the present invention. see figure 1 , a kind of preparation method of resin graphene composite material, comprises the steps:

[0034] (1) Mix and stir the metal additive, graphene material and water to obtain a slurry, so that the graphene material and the metal additive undergo complexation and chelation reactions to increase the graphene surface active sites.

[0035] Preferably, the mass ratio of the metal additive to the graphene material is 1:3-10; the stirring is carried out at a temperature of 80-90° C. for 4-8 hours, and the viscosity of the slurry is 200-300 cp.

[0036] That is, put metal additives and graphene materials in a mass ratio of 1:3-10, add them into a stirred reactor filled with deionized water for stirring, and keep the viscosity of the slurry at 200-300cp, and raise the temperature under normal pressure To 80-90 ℃ constant temperature re...

Embodiment 1

[0059] A kind of preparation method of resin graphene composite material, comprises the steps:

[0060] (1), metal additives, graphene material and water are mixed and stirred to obtain slurry;

[0061] (2), drying slurry obtains metal-based graphene;

[0062] (3) Obtained by heating metal-based graphene and thermoplastic resin to 200° C. in an inert gas atmosphere.

Embodiment 2

[0064] (1) Put metal additives and graphene materials in a mass ratio of 1:3, add them into a stirred reactor filled with deionized water for stirring, and keep the viscosity of the slurry at 200 cp, and heat up to 80 cp under normal pressure. The reaction was carried out at constant temperature at ℃ for 4 h to obtain a slurry.

[0065] (2) The slurry is subjected to spray granulation and drying to obtain a metal-based graphene rich in a large number of active sites with a particle size of about 10 μm.

[0066] (3), first add the metal-based graphene into the high-temperature reaction kettle filled with the reaction carrier, stir evenly, then add thermoplastic resin to continue stirring (the mass ratio of metal-based graphene to thermoplastic resin is 1:5), and stir After uniformity, add 500ppm of surfactant, and react for 4 hours under the conditions of keeping the reaction pressure at 50kpa and the reaction temperature at 295±5°C in an inert gas atmosphere to obtain the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com