High-frequency magnetic spectrograph

A spectrometer and high-frequency technology, applied in the field of material surface magnetic measurement, can solve the problems of inability to obtain magnetization dynamic information, inability to obtain nanoscale magnetization dynamic characteristics, imaging effect is easily limited by optical components, etc., to achieve fast test speed and use The effect of long life and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

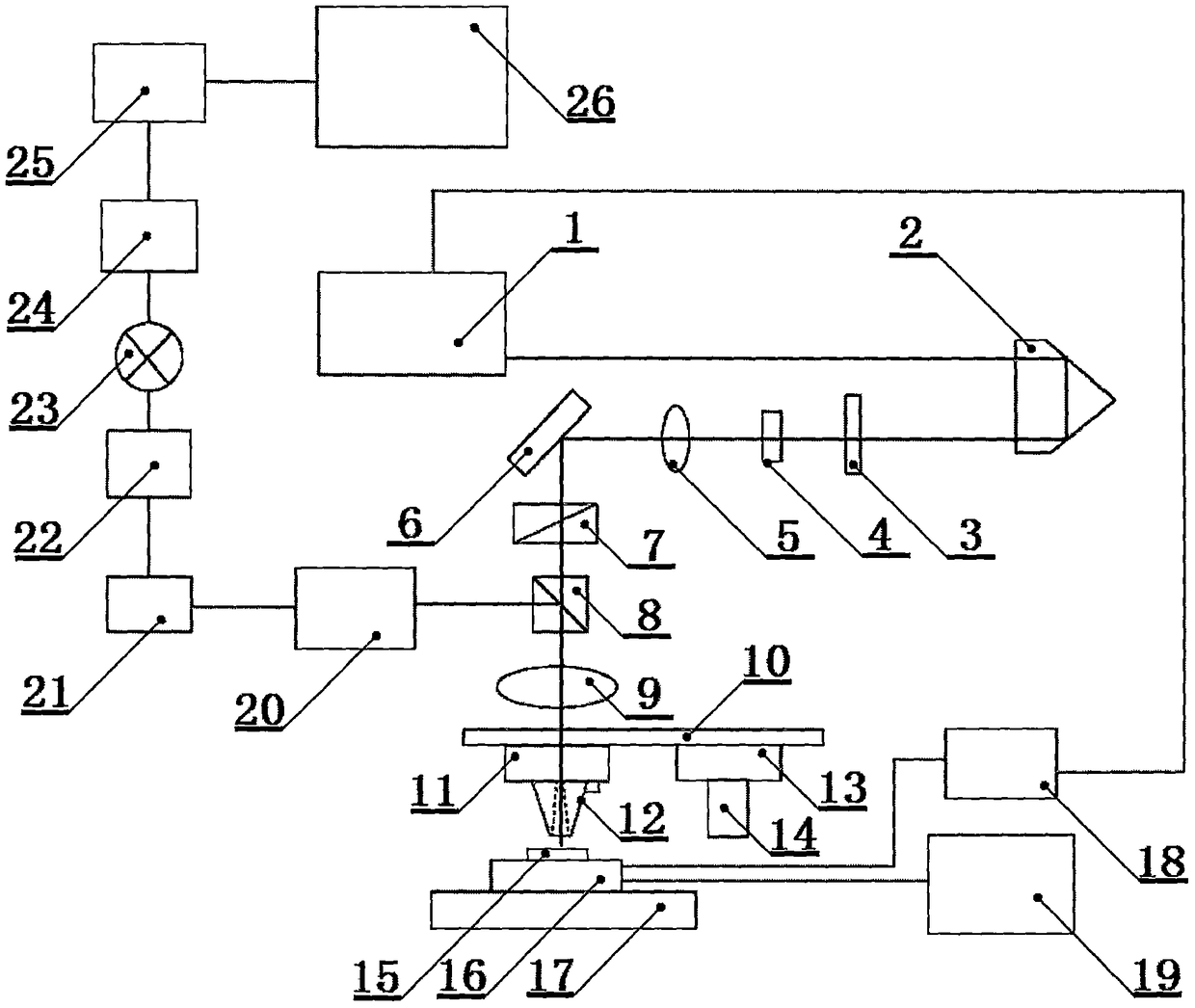

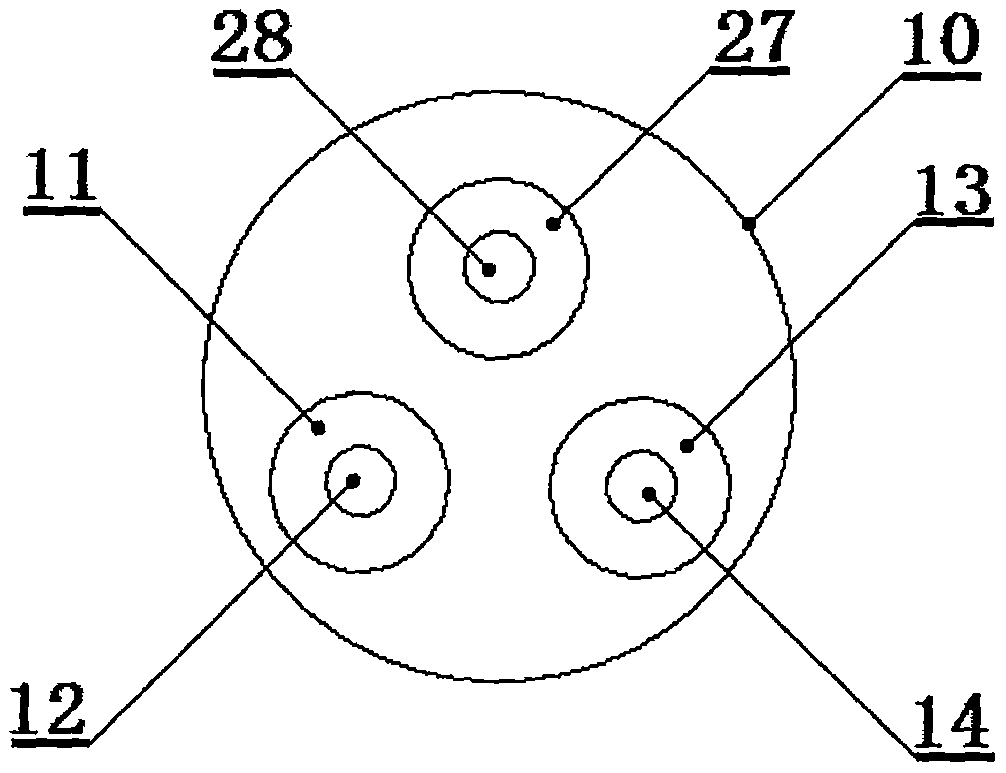

[0027] Such as figure 1 It is a schematic diagram of the present invention, the pulsed laser 1, the signal generator 18, the waveguide 16, and the oscilloscope 19 are connected by cables in turn, and the optical bridge detector 20, the bias tee 21, the amplifier I 22, the mixer 23, and the amplifier II 24, analog-to-digital converter 25, computer 26 cable connection successively, the laser beam that described pulse laser 1 emits successively through delayer 2, 1 / 4 wave plate 3, concave lens 4, convex lens 1 5, plane mirror 6, polarizer 7 , beam splitter 8, convex lens II 9, lens stand 10, atomic force microscope I11, probe I 12, thereby forming an incident light path, the reflected light generated by the laser beam irradiating on the surface of sample 15 passes through probe I 12, atomic force microscope in turn I 11, lens stand 10, convex lens II9, beam splitter 8, thereby forming a reflected light path, the reflected light is deflected to the optical bridge detector 20 by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com