Experimental device and method based on pulsed Townsend method

An experimental device and pulse technology, applied in the direction of measuring devices, instruments, measuring electronics, etc., can solve the problems of the influence of experimental accuracy and low repeatability of electrode distance, and achieve the effect of fast analysis speed, high quantum efficiency and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

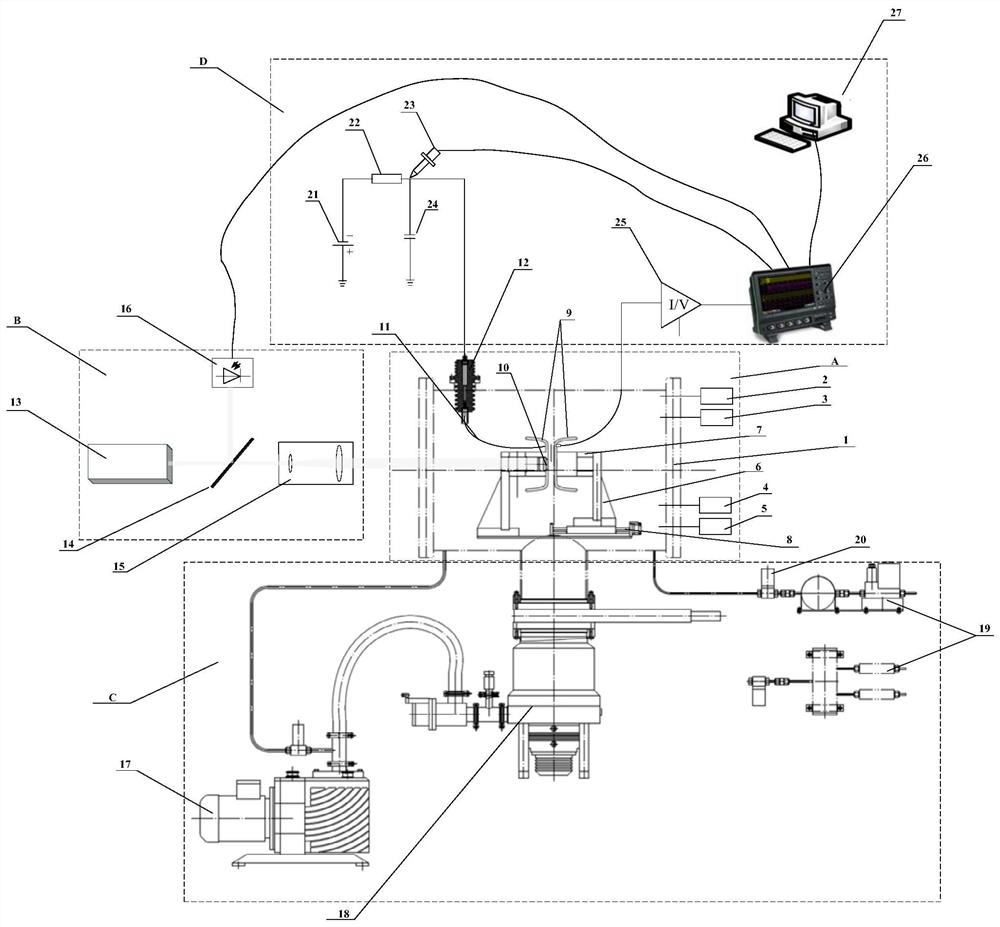

[0072] see figure 1 , the present invention is based on the pulse Thomson method experimental device, the device includes a vacuum chamber A, an optical system B, a vacuum system C and a measurement system D.

[0073] The vacuum cavity A is connected with the optical system B and the vacuum system C respectively. Optical system B is connected to measuring system D.

[0074] The vacuum chamber A includes a vacuum chamber 1, a first membrane gauge barometer 2, a second membrane gauge barometer 3, a micro-water content detector 4, a micro-oxygen content detector 5, an electrode support 6, an electrode insulating connector, Vacuum displacement stage 8 , Rogowski electrode 9 , photocathode coated glass 10 , high voltage cable 11 and insulating sleeve 12 .

[0075] The vacuum chamber 1 is a stainless steel chamber with a length and a diameter of 55 cm and a volume of about 130 liters.

[0076] One side of the vacuum chamber 1 is provided with a first thin-film gauge barometer 2 ,...

Embodiment 2

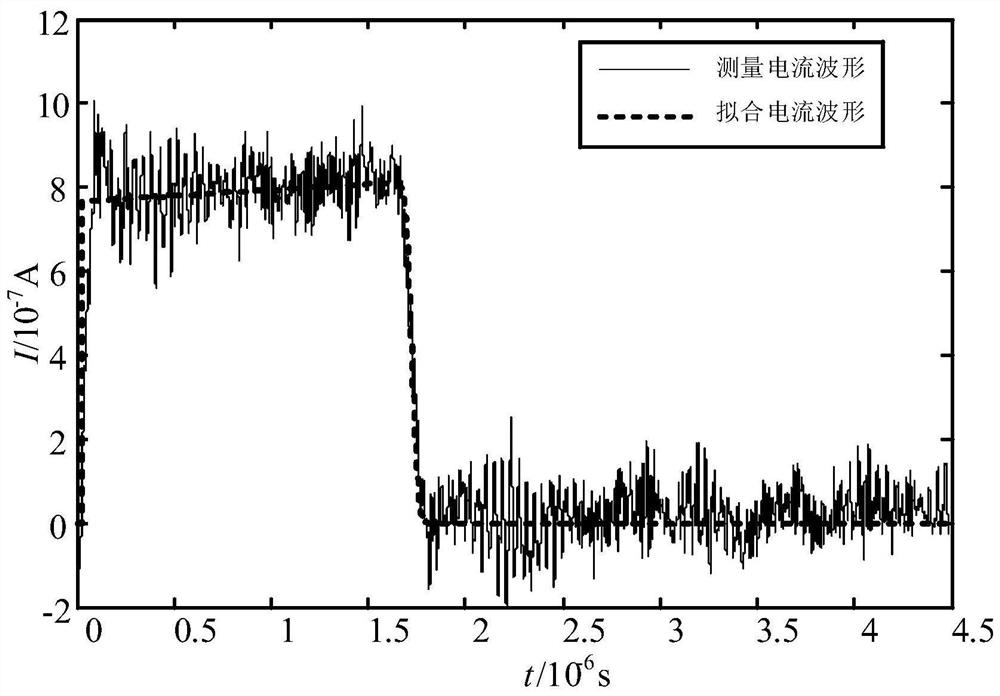

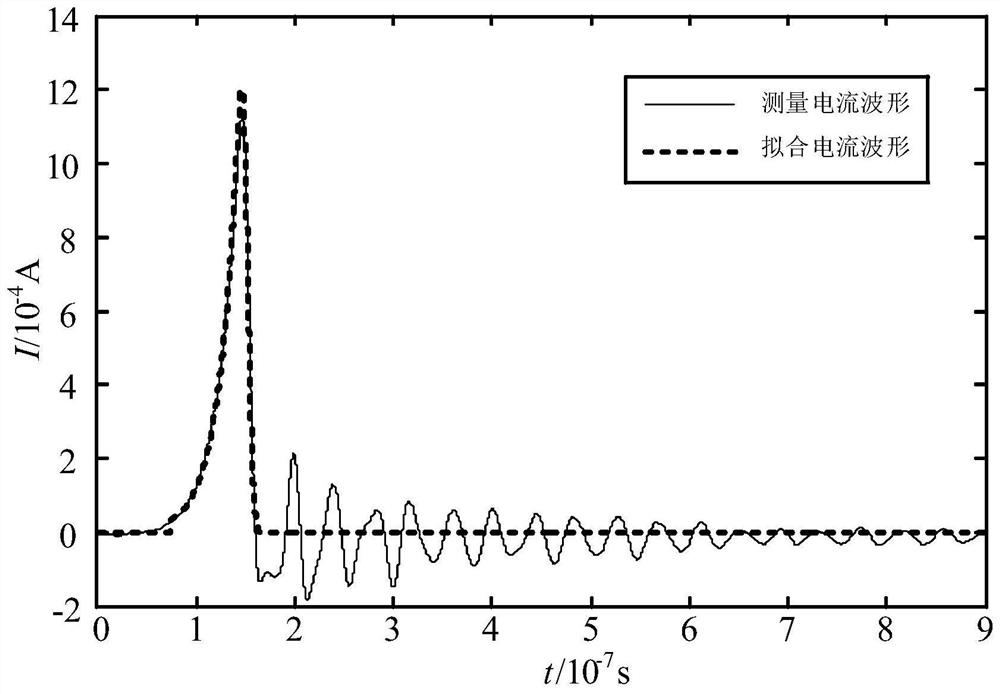

[0124] A kind of experimental data processing method based on pulse Thomson's method, concrete workflow of the present invention is as follows (taking the experiment to 10kPa pure carbon dioxide as example):

[0125] 1. Parameter setting.

[0126] Such as Figure 6 As shown in the work flow chart of the parameter setting link, first open the end cover of the cavity to replace the photocathode glass, then control the moving electrode to move to the static electrode until it is closed and tested for continuity by a multimeter, and then reset the distance to zero.

[0127] Next, after controlling the vacuum displacement table 8 to move the movable electrode to the desired set spacing position, the power supply of the vacuum displacement table 8 is cut off.

[0128] Turn on the mechanical pump 17 to evacuate the cavity below 8Pa, then turn on the molecular pump 18 and open the flapper valve to evacuate the vacuum chamber 1 to below 5×10-5.

[0129] Close the slide valve and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com