Cleaning and sweeping device and method and mechanical arm for cleaning and sweeping wafer

A cleaning device and robotic arm technology, applied in the fields of cleaning devices, robotic arms, and methods, can solve problems such as poor focusing, image defects, and impact on wafer yield, so as to improve production yield, reduce contamination particles, and prevent crossover. Effects of contamination and workmanship defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention adds a particle cleaning function on the robotic arm (ARM) used to transfer wafers, and purges through high-pressure gas (such as nitrogen), thereby preventing the particles adsorbed on the back of the wafer in the previous process machine from being brought into the The next process machine will cause problems such as cross-contamination of the machine, which improves the production yield. A detailed description will be given below in conjunction with the accompanying drawings and embodiments.

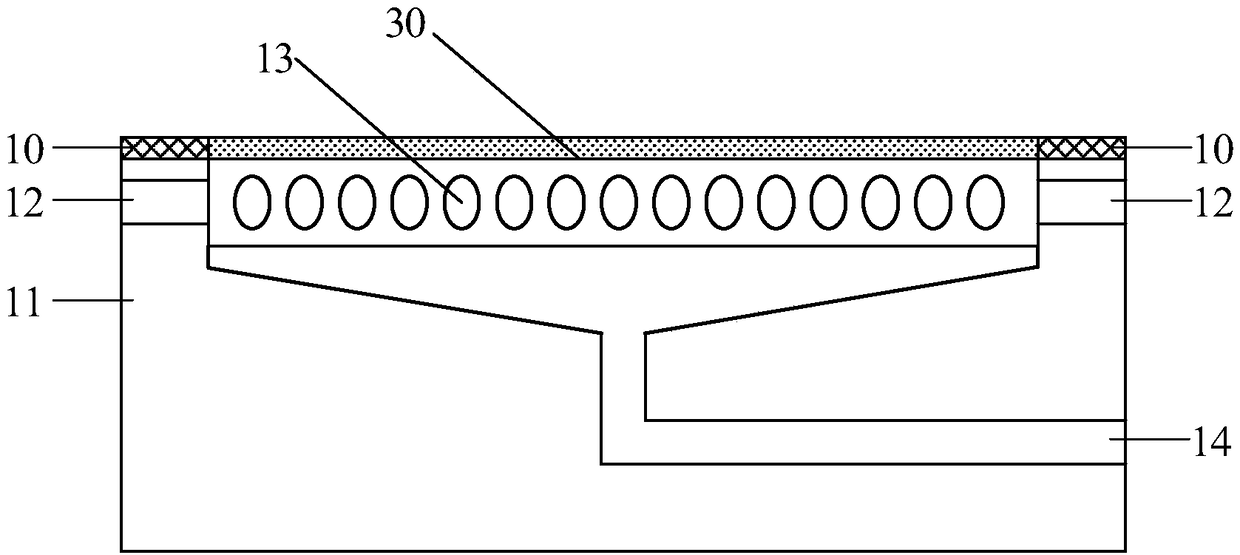

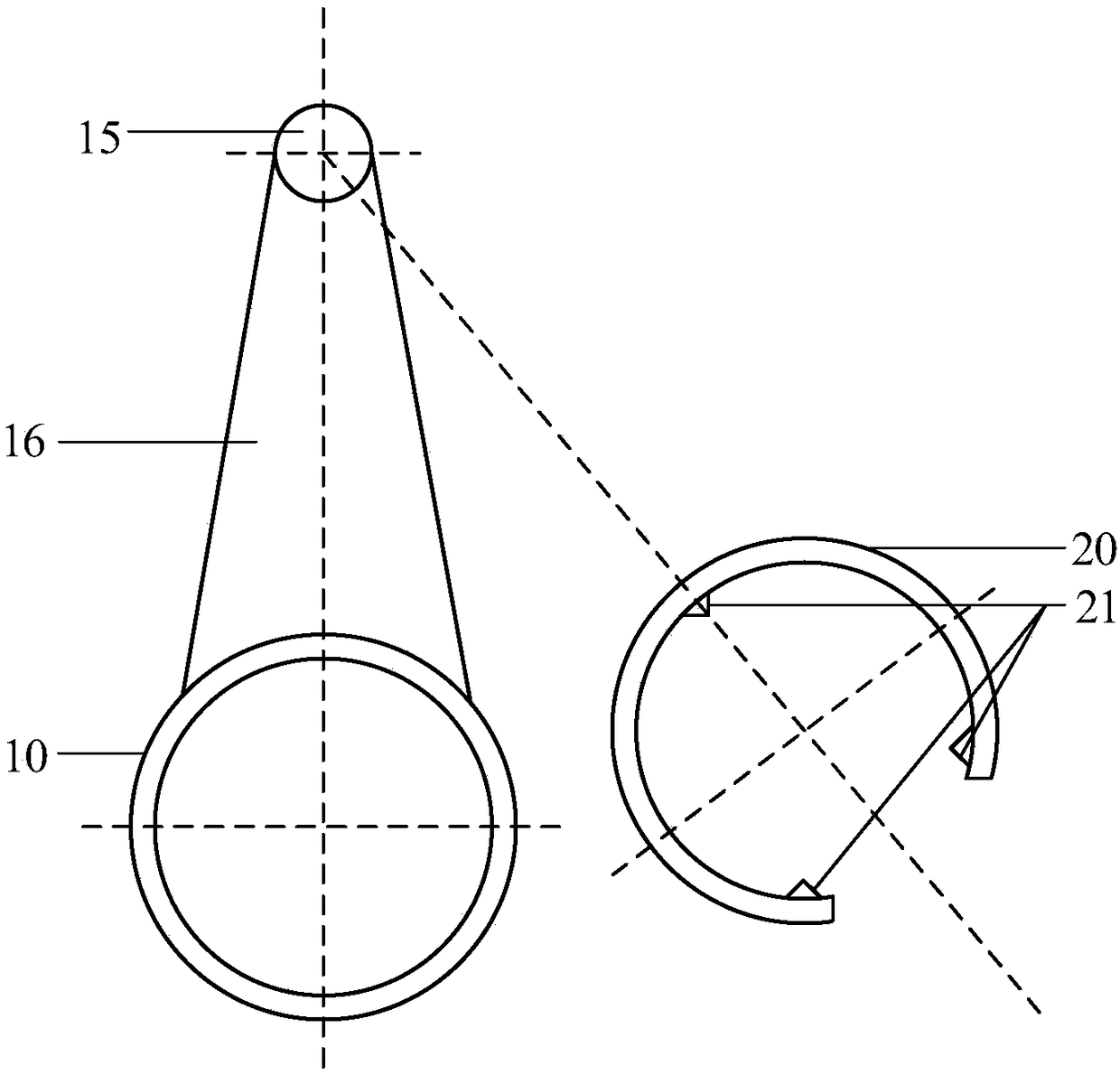

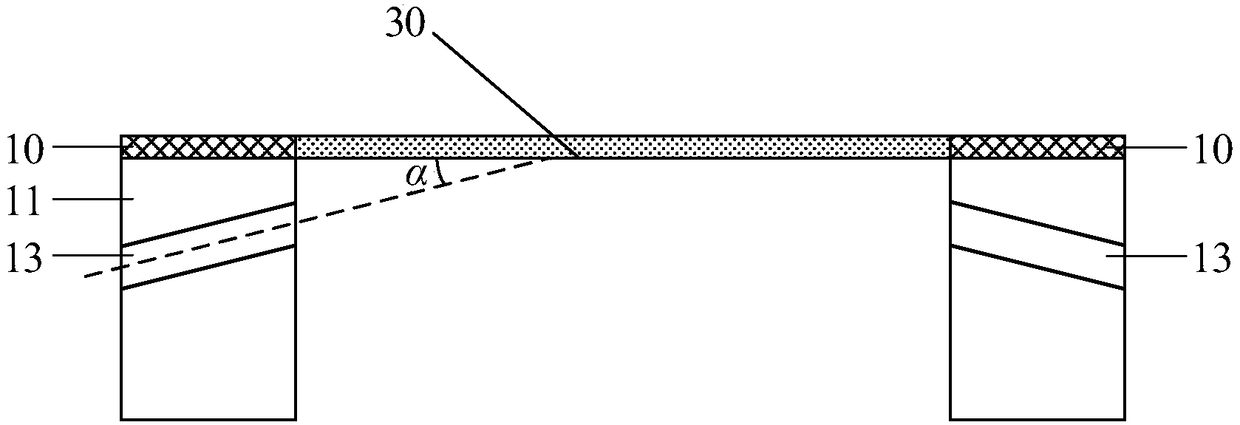

[0029] Please refer to figure 1 The schematic cross-sectional structure of the cleaning device is shown. The cleaning device according to the embodiment of the present invention includes: an adsorption part 10 and a cleaning mechanism; the cleaning mechanism includes a support part 11 , an air inlet 12 and a cleaning hole 13 .

[0030] The adsorption part 10 is used for adsorption under the grasping part of the mechanical arm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com