Muddy water balance control test system of muddy water balance shield machine comprehensive simulation test table

A technology for simulating test bench and mud-water balance, applied in teaching models, instruments, mining equipment, etc., can solve the problems of inconsistent work flow, mud-water circulation system cannot completely simulate the pressure adjustment process of mud-water tank, soil box cannot be loaded, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

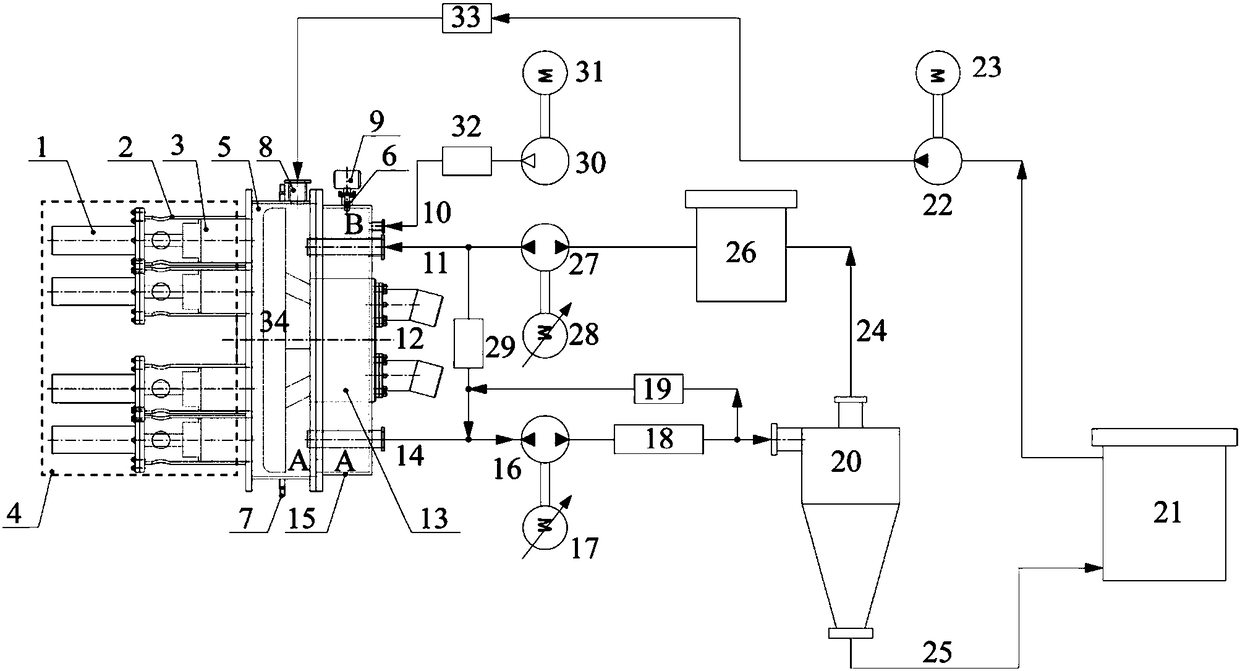

[0034] Examples of the present invention will be further described below in conjunction with the accompanying drawings.

[0035] Such as figure 1 As shown, one end face of the muddy water pressurizing cylinder 5 is closed by a cover plate, and several muddy water loading devices 4 are installed on the cover plate, and the other end of the muddy water pressurizing cylinder 5 is connected to one end of the front shield 15 of the simulated shield machine, and the muddy water loading The pressure cylinder 5 and the simulated shield front shield 15 are connected to each other, the overall space in the pressurized cylinder 5 of the mud tank and the bottom space in the simulated shield front shield 15 form a mud tank A, and the top of the simulated shield front shield 15 The space forms the air cushion cabin B.

[0036] Such as figure 1 As shown, a closed cutter head 34 is arranged and installed in the pressurized cylinder body 5 of the mud tank, and a main drive gearbox 13 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com