Horizontal effective ground stress testing method considering drilling fluid pressure and testing device

A stress test, effective technology, applied in the direction of the measuring device, the force sensor in the hole of the force-bearing structure, the component of the measurement force, etc., can solve the cumbersome and complicated operation of the stress test method, hinder the accuracy of the stress, Problems such as success rate and test efficiency, and the influence of ground stress are not taken into account, so as to achieve the effect of facilitating popularization and application, simple structure, and simplified operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

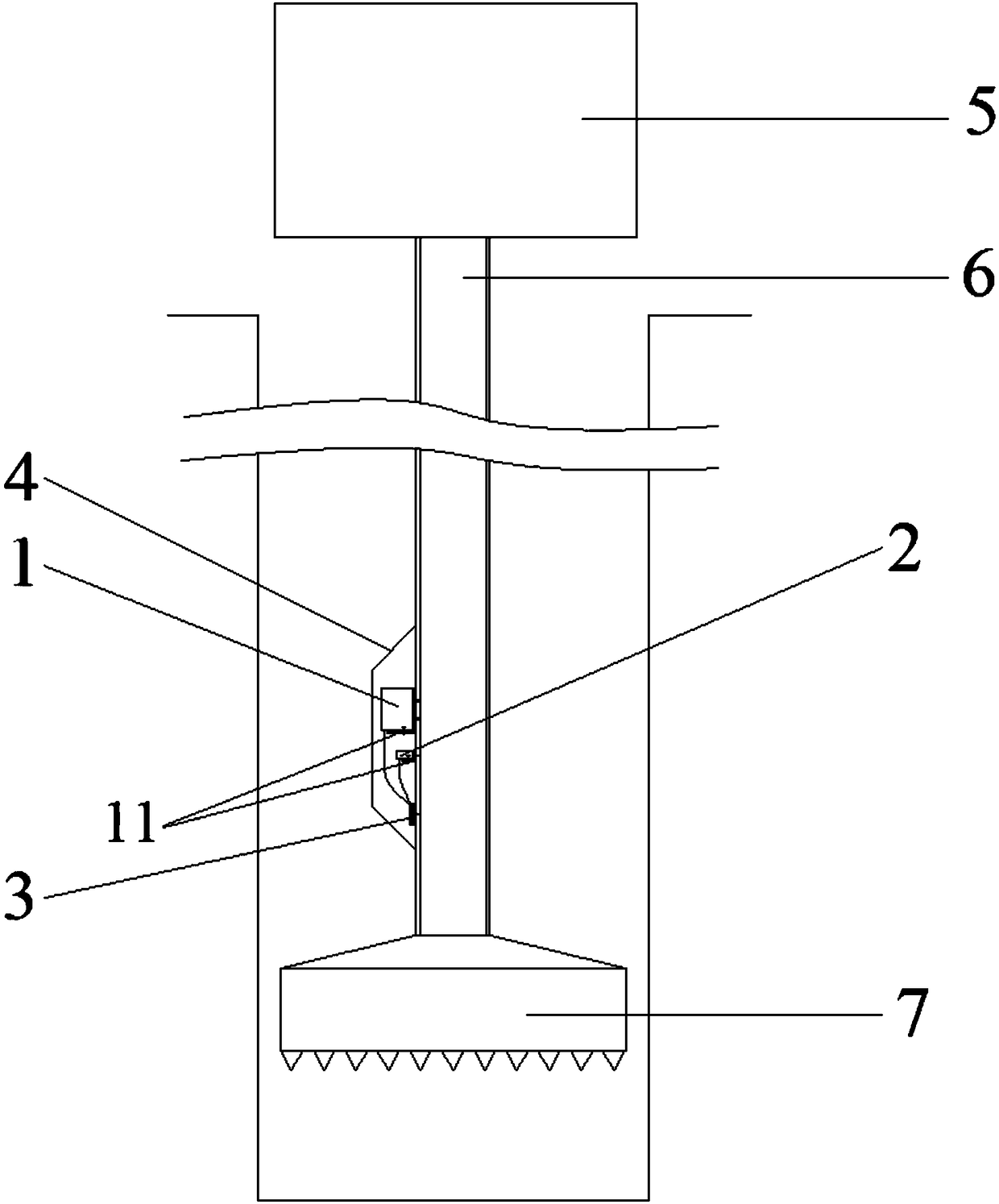

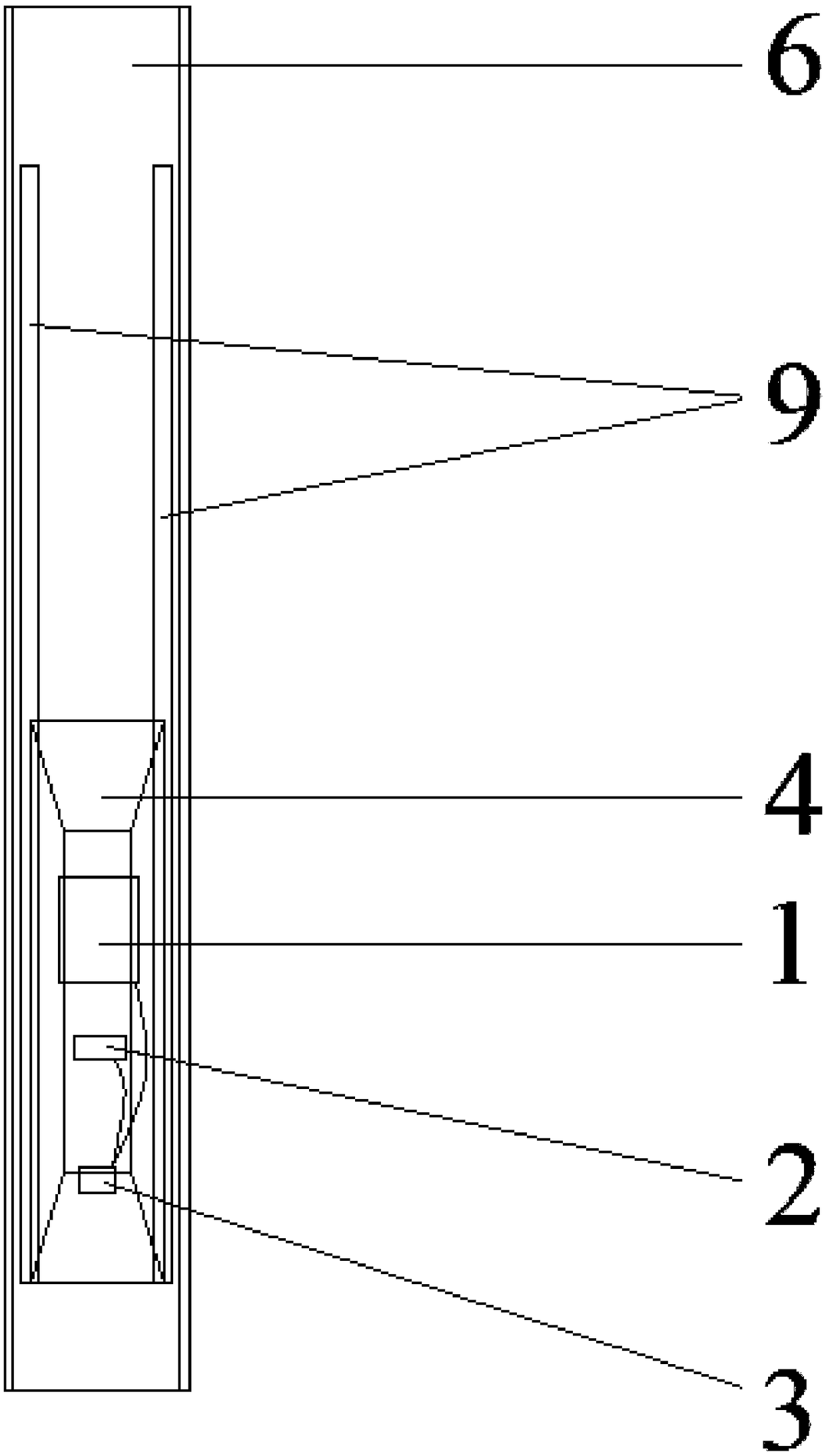

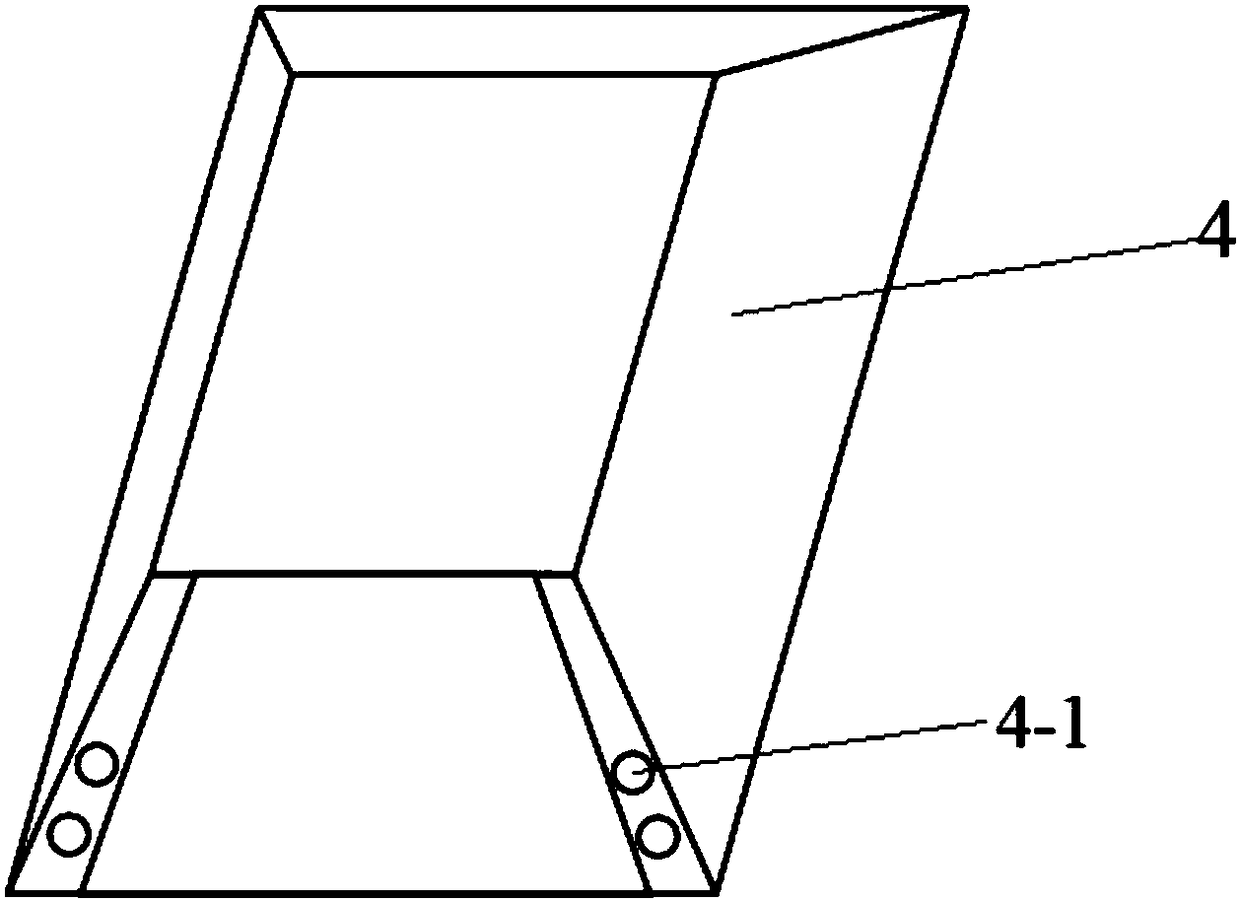

[0036] In this embodiment, the structure of the horizontally effective stress testing device is as follows figure 1 As shown, the horizontal effective stress test device is suitable for testing horizontal effective stress in boreholes perpendicular to the horizontal plane, including a multi-scale phase laser rangefinder 1, a three-dimensional electronic compass 2, and a multi-scale laser for integrating and storing Phase laser rangefinder 1 and three-dimensional electronic compass 2 data memory 3 for measurement data, transparent protective cover 4, drilling machine 5, drill pipe 6 and drill bit 7, the drill pipe includes several pieces, and each drill pipe is connected by thread, The drill bit 7 is connected with the drilling machine 5 through the drill rod 6. The diameter of the drilled hole drilled by the drill bit is 9cm larger than the outer diameter of the drill rod. and measurement accuracy requirements, you can choose to buy from the market, or you can choose to custom...

Embodiment 2

[0039] In this embodiment, the structure of the horizontally effective stress testing device is similar to figure 1 , the horizontal effective stress testing device is suitable for testing the horizontal effective stress in a borehole perpendicular to the horizontal plane, including a multi-scale phase laser rangefinder 1, a three-dimensional electronic compass 2, and a multi-scale phase laser for integrating and storing The data memory 3 of the measurement data of the rangefinder 1 and the three-dimensional electronic compass 2, the transparent protective cover 4, the drilling rig 5, the drill rod 6 and the drill bit 7, the drill rods include several roots, and the drill rods are connected by threads, and the drill bit 7 The drill rod 6 is connected with the drilling machine 5, and the diameter of the drilled hole drilled by the drill bit is 10 cm larger than the outer diameter of the drill rod. The measurement accuracy of the multi-light ruler phase laser range finder 1 is 2....

Embodiment 3

[0042] In this embodiment, a horizontal effective stress testing method considering the drilling fluid pressure is provided. The method uses the horizontal effective stress testing device in Embodiment 1 or 2 for testing, and the steps are as follows:

[0043] ①Determine the target rock mass to be subject to horizontal effective in-situ stress, explore or consult the lithology of the rock formations at different depths of the target rock mass according to the exploration data, and use indoor uniaxial compression tests to measure the elastic modulus and Poisson's ratio of rock formations at different depths;

[0044] ② Drill a hole perpendicular to the horizontal plane on the target rock mass. During the drilling process, the drilling fluid is passed to cool the drill bit. When the position of the multi-scale phase laser rangefinder in the hole reaches the target depth, the drilling is stopped. , check the position of the drill pipe in the drill hole, ensure that the axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com