Method for determining content of fluorine in mold flux for continuous casting

A technology of continuous casting mold flux and fluorine content, applied in the fields of analytical chemistry and metallurgy, can solve problems such as environmental pollution, reduce the service life of production equipment, etc., and achieve the effect of strong shielding of interfering ions, increase of melting temperature, and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] 1. Processing of mold flux samples: Weigh 0.1000 g of three ground mold flux samples (No. 1) into a corundum crucible, and then weigh 1.1 g of Na 2 o 2 and 0.6 g of ZnO flux in a crucible, after mixing, place it in a muffle furnace heated to about 400°C, raise the temperature to 780°C, keep the temperature constant for 20 minutes, slightly open the furnace door, and wait for the temperature of the muffle furnace to drop to 400°C Take out the crucible when left or right; after it cools down slightly, soak the sample in the crucible with hot water, filter it into a 100 mL plastic volumetric flask, wash with water and make up to volume.

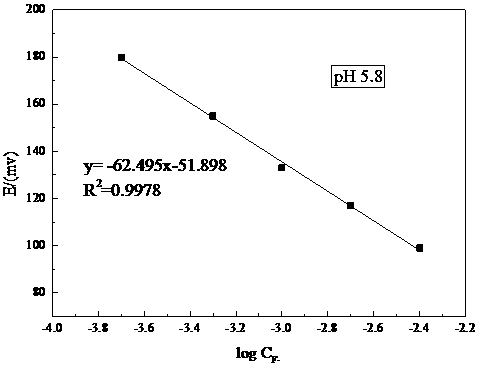

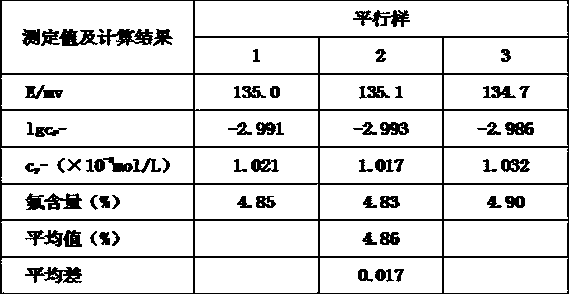

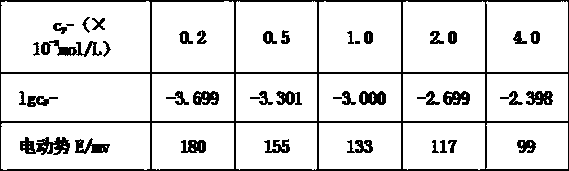

[0035] 2. Determination of fluorine content in the sample solution: Separately take 10mL of the above test solution into a 25mL volumetric flask, add 10mL of total ionic strength buffer solution (pH5.8), constant volume, shake well, and place in a constant temperature water bath for constant temperature to 30°C; pour the test solution in...

example 2

[0041] 1. Processing of mold flux samples: Weigh 0.1000 g of 3 parts of ground mold flux samples (No. 2) into corundum crucibles, and then weigh 1.2g of Na 2 o 2 and 0.6 g of ZnO flux in a crucible, after mixing, place it in a muffle furnace heated to 450 °C, heat up to 800 °C, keep the temperature for 20 min, slightly open the furnace door, and wait for the temperature of the muffle furnace to drop to about 400 °C Take out the crucible; after it cools slightly, soak the sample in the crucible with hot water, filter it into a 100 mL plastic volumetric flask, wash it with water and make it to volume.

[0042] 2. Determination of fluorine content in the sample solution: Separately take 10mL of the above test solution into a 25mL volumetric flask, add 10mL of total ionic strength buffer solution (pH5.8), constant volume, shake well, and place in a constant temperature water bath for constant temperature to 30°C; pour the test solution into a 50 mL plastic beaker in turn, use a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com