Meshless RKPM-based two-dimensional thermal deformation and stress analysis method for anisotropic material structure

A technology of material structure and anisotropy, applied in the field of numerical heat transfer, can solve problems such as limitations, no consideration of thermal deformation and thermal stress, no research on thermal deformation and thermal stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

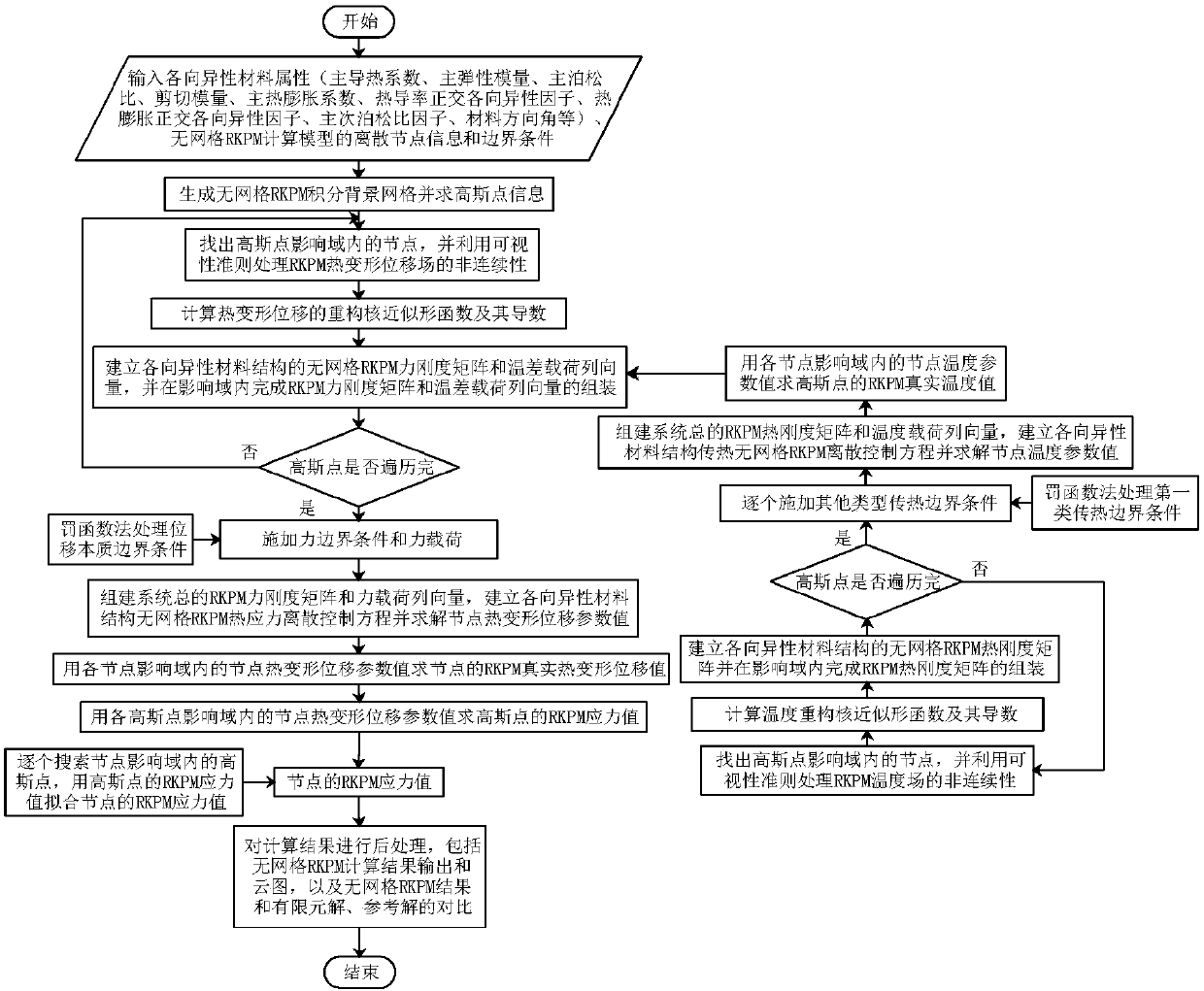

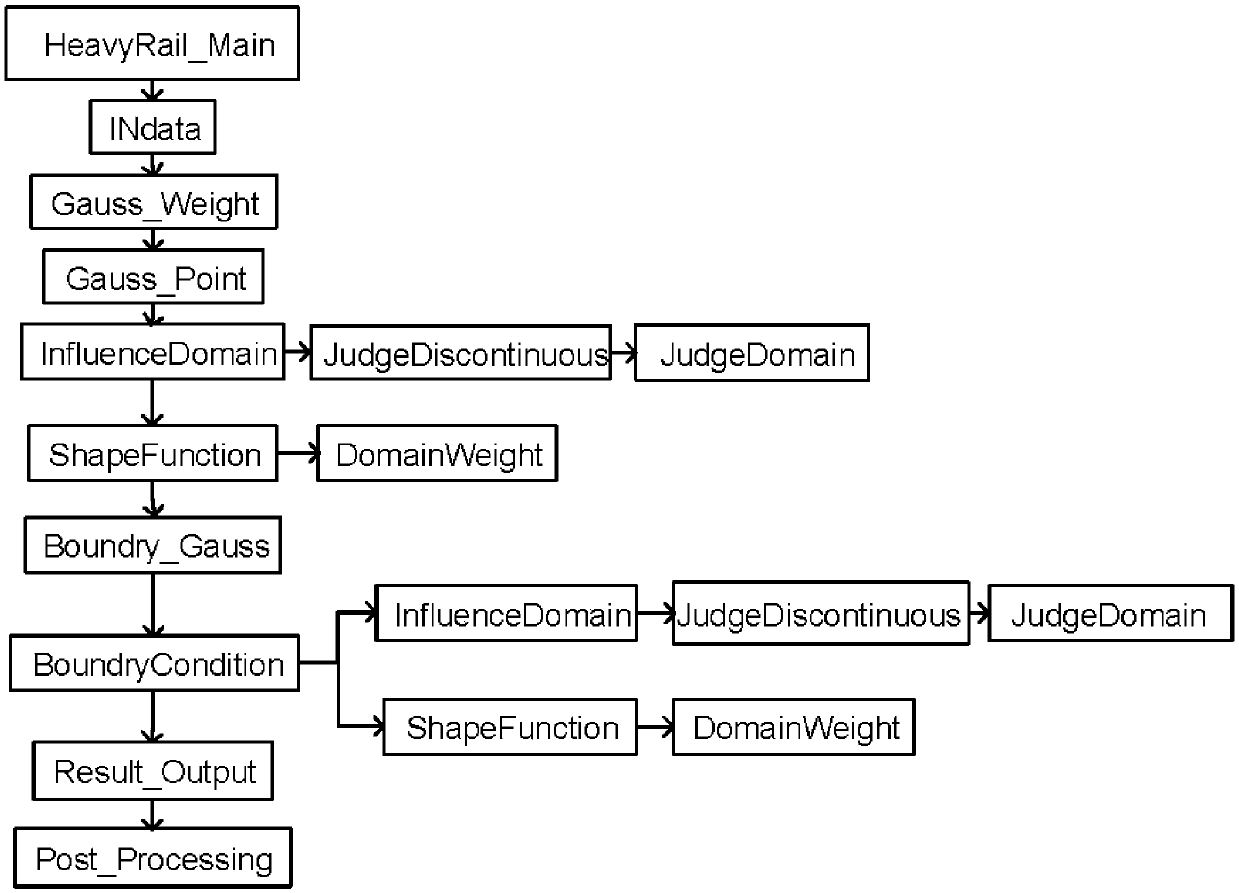

[0061] see figure 1 and figure 2 , the analysis method of two-dimensional thermal deformation and thermal stress of anisotropic material structure based on meshless RKPM mainly includes the following steps:

[0062] First, the conversion relationship between the thermal conductivity, stress component and strain component between the geometric coordinate system X—Y and the material coordinate system 1—2 is established, and the heat flux along the geometric coordinate axis direction is:

[0063]

[0064]

[0065] In the above formula, λ ij (i,j=1,2) is the thermal conductivity coefficient that varies with geometric coordinates, is the transformation matrix, λ 1 and lambda 2 is the thermal conductivity in the 1 and 2 directions of the principal axes of the material coordinate system. Define the material's thermal conductivity orthotropic factor Ht = λ 1 / λ 2 .

[0066] The relationship between the thermal stress component and the strain component is established as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com