Piezoelectric array element manufacture method for high-frequency endoscopic ultrasound transducer

An ultrasonic transducer, piezoelectric array element technology, applied in ultrasonic/sonic/infrasonic diagnosis, application, acoustic diagnosis and other directions, can solve the complex production method of piezoelectric array element, transducer assembly difficulty, low yield, etc. problem, to the effect of simplifying the wire connection process and reducing the possibility of poor wire contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

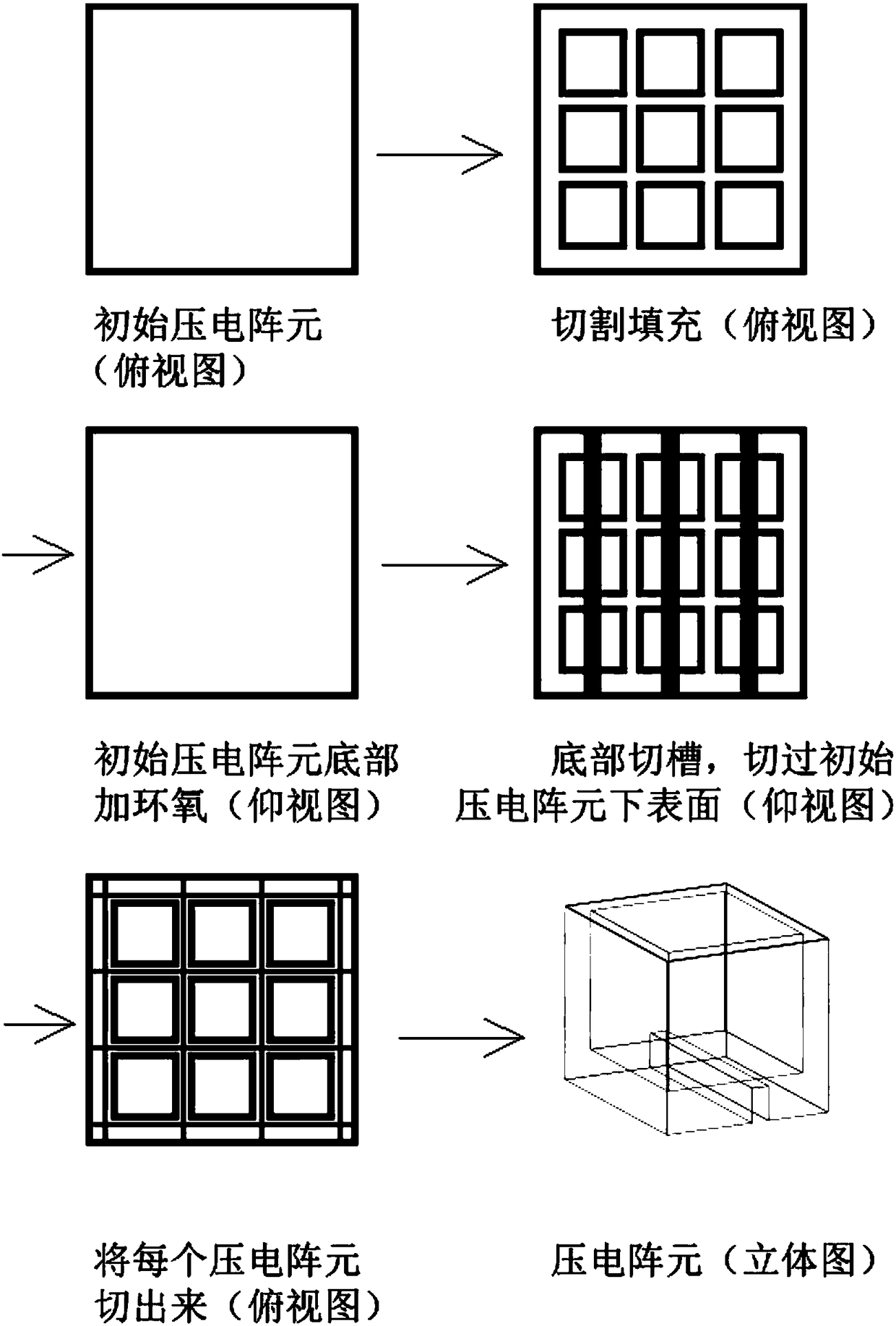

Embodiment 1

[0024] A method for manufacturing a piezoelectric array element for high-frequency endoscopic ultrasonic transducers, the piezoelectric single crystal material PMN-PT with electrodes on the upper and lower sides, and epoxy resin doped with silver particles on the upper side as the first For the matching layer, the conductive material E-solder3022 is added on the lower side as the backing layer. Use a diamond knife with a blade width of 0.1mm to cut it into 0.4mm×0.4mm array element blocks on a cutting machine, and the interval between array element blocks is 0.1mm at this time. Fill epoxy into the kerf, and grind off excess epoxy after curing. Turn the piezoelectric element over, add an epoxy resin layer, grind it flat after curing (the thickness of epoxy at the bottom is 0.025mm), cut through the epoxy and slightly cut through the lower surface of the backing layer when cutting the groove. Then turn the piezoelectric array element over, and use a diamond knife with a blade w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com