Marine carbon fiber composite large lateral oblique propeller blade and design method thereof

A technology of composite materials and propeller blades, applied in ship design, rotating propellers, ship components, etc., can solve the problems of increasing the difficulty of excellent composite material blade models, imperfect design methods, slow independent innovation and development process, etc., to promote Engineering application, light weight, low vibration and noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A design method for large skewed propeller blades of marine carbon fiber composite materials, comprising:

[0045] Step 1, design the parent metal material blade of the carbon fiber composite material large-slope blade;

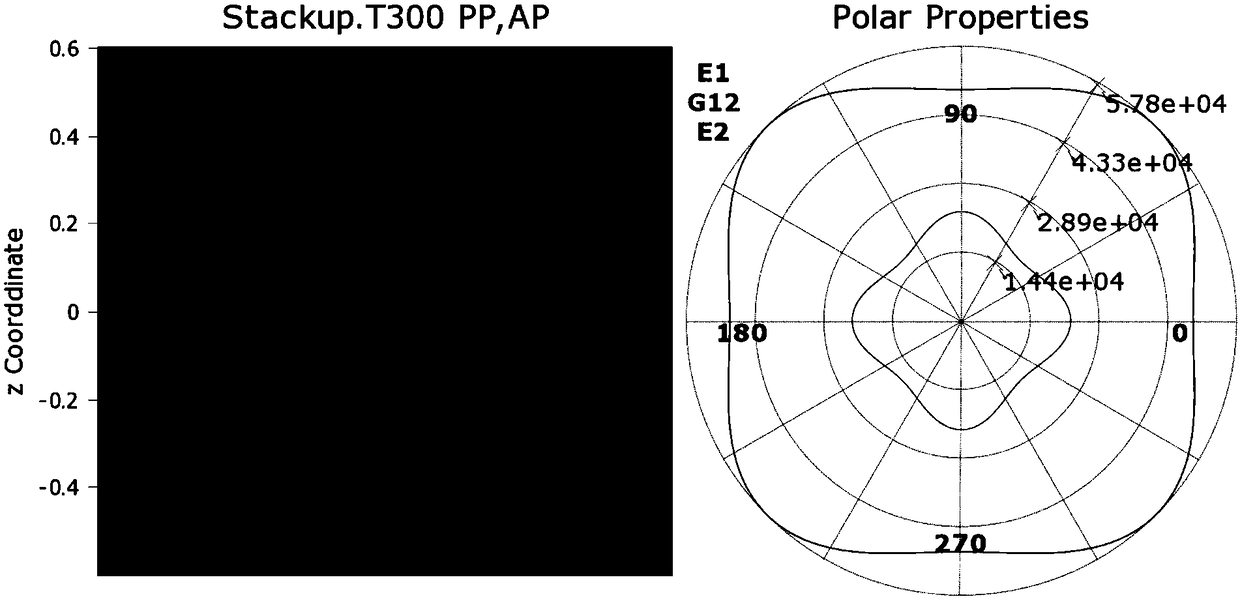

[0046] Step 2, determining the lay-up arrangement scheme of the carbon fiber laminate unit, including lay-up angle, lay-up sequence and lay-up thickness;

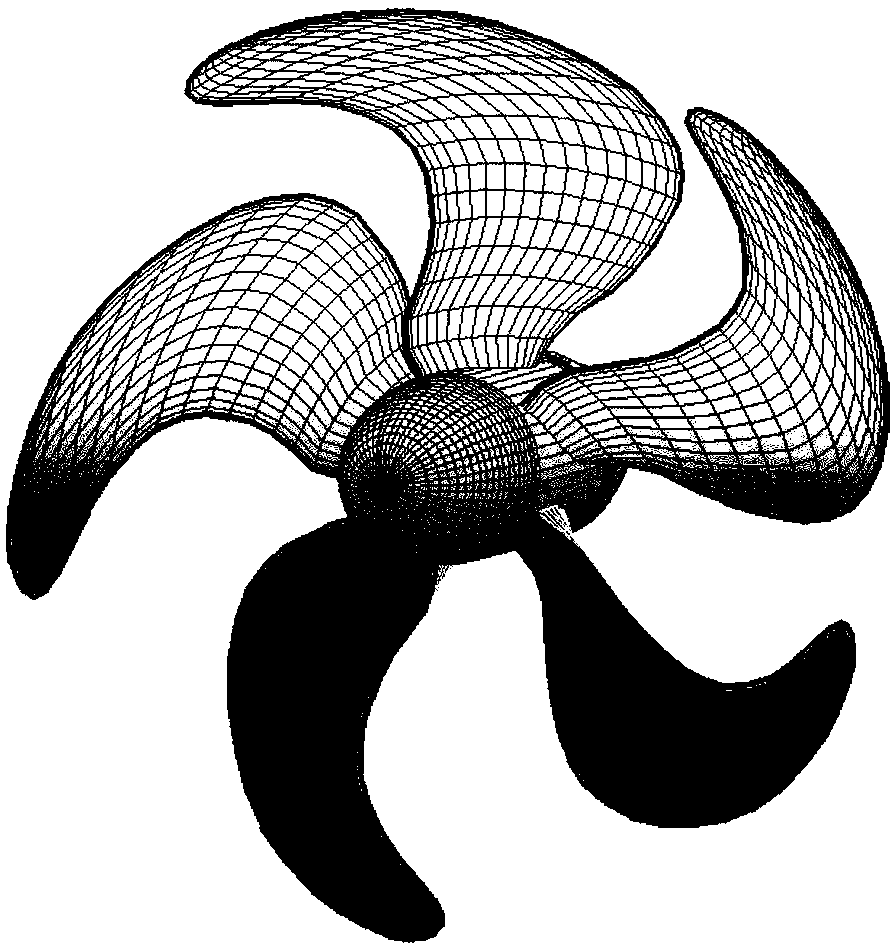

[0047] Step 3, stacking the results obtained in step 2 to generate a solid geometric model of a single carbon fiber composite material large-slope blade, and then copying the circumferential rotation to obtain several composite material large-slope blade solid geometric models;

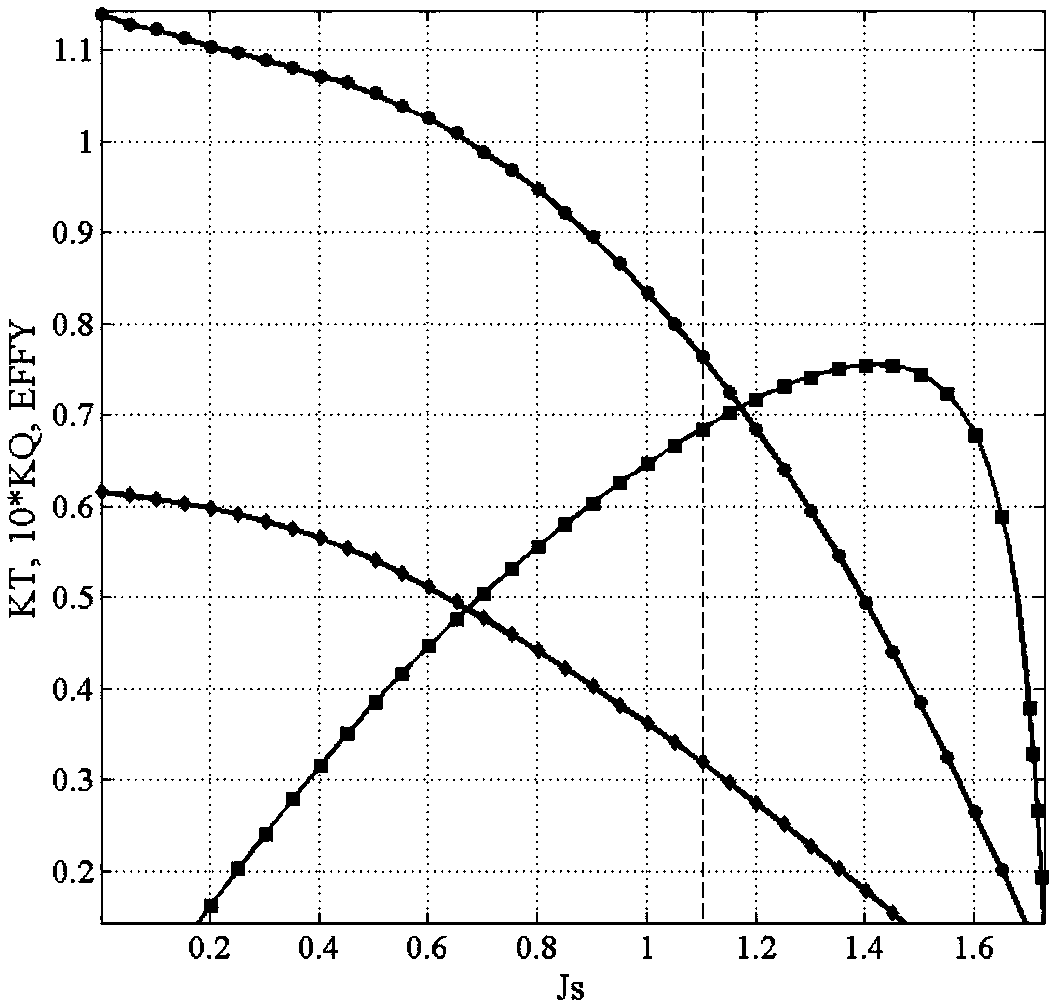

[0048] Step 4. Calculate the hydrodynamic performance of the model obtained in step 3. The hydrodynamic performance includes hydrodynamic efficiency. Determine whether the difference between the hydrodynamic efficiency and the parent large-slope metal blade obtained in step 1 is within the preset range. If so , then go to ...

Embodiment 2

[0077] A marine carbon fiber composite large-slope propeller blade designed by the method described in Example 1: the blade is stacked by several carbon fiber laminated units to generate a solid geometric model of a single carbon fiber composite large-slope blade, and a single carbon fiber composite The solid geometric model of the high-skew blade made of material is copied in the circumferential direction to obtain N solid geometric models of the large-skewed blade of composite material, and N is the number of blades of the solid geometric model of the large-skewed blade of composite material.

[0078] The number of blades N is 5; the hydrodynamic efficiency of the blades is greater than 0.65. The carbon fiber laminate unit is composed of 6 layers of unidirectional carbon fiber woven fabrics. The angles of the woven fabrics are 0°, -30°, and -45° from bottom to top , 45°, 30° and 0°, the thickness ratio of the woven fabric layer from bottom to top is 1:2:2:1:1:1.

[0079] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drag | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com