Frozen-soil natural gas hydrate storage compound type drilling fluid

A drilling fluid and natural gas technology, applied in the field of natural gas hydrate exploitation, can solve the problems of not considering the use of compound hydrate inhibitors, and achieve the effects of avoiding serious expansion of pore diameter, good low temperature stability, and preventing lost circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, the content of each component in the drilling fluid is: the mass ratio of sodium silicate is 2.8%, the mass ratio of sodium chloride is 7%, the mass ratio of ethylene glycol is 19%, the mass ratio of potassium polyacrylate is 1.8%, low The mass ratio of viscosity polyanionic cellulose LV-PAC is 1.8%, the mass ratio of xanthan gum is 0.4%, the mass ratio of polyvinyl caprolactam is 0.8%, the mass ratio of polyvinyl methyl ether is 0.8%, tetra-n-hexyltri The mass ratio of methyl ammonium bromide is 0.8%, and the remaining components are prepared water.

Embodiment 2

[0040] Embodiment 2, the content of each component in the drilling fluid is: the mass ratio of sodium silicate is 3%, the mass ratio of sodium chloride is 7.5%, the mass ratio of ethylene glycol is 20%, the mass ratio of potassium polyacrylate is 2%, low The mass ratio of viscosity polyanionic cellulose LV-PAC is 2%, the mass ratio of xanthan gum is 0.5%, the mass ratio of polyvinyl caprolactam is 1%, the mass ratio of polyvinyl methyl ether is 1%, tetra-n-hexyltri The mass ratio of methyl ammonium bromide is 1%, and the remaining components are prepared water.

Embodiment 3

[0041] Embodiment 3, the content of each component in the drilling fluid is: the mass ratio of sodium silicate is 3.2%, the mass ratio of sodium chloride is 8%, the mass ratio of ethylene glycol is 21%, the mass ratio of potassium polyacrylate is 2.2%, low The mass ratio of viscosity polyanionic cellulose LV-PAC is 2.2%, the mass ratio of xanthan gum is 0.6%, the mass ratio of polyvinyl caprolactam is 1.2%, the mass ratio of polyvinyl methyl ether is 1.2%, tetra-n-hexyltri The mass ratio of methyl ammonium bromide is 1.2%, and the remaining components are prepared water.

[0042] The drilling fluid configuration methods of the above-mentioned examples 1, 2, and 3 are conventional drilling fluid configuration methods, and are evaluated by the following experimental methods:

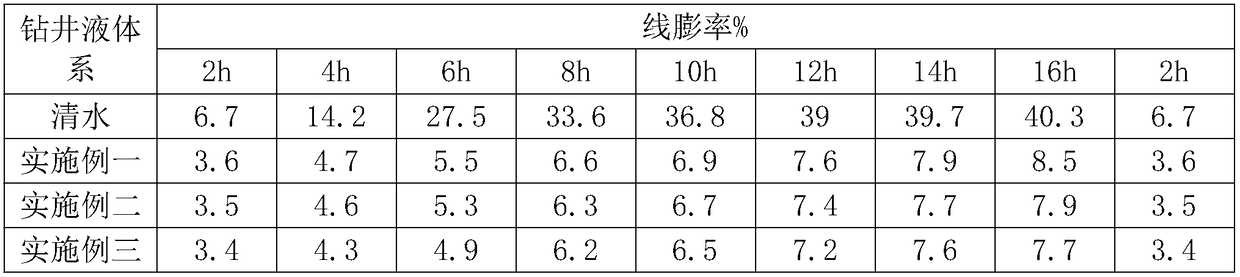

[0043] 1 Evaluation of drilling fluid shale hydration inhibition

[0044] Inhibition evaluation experiment is an important part of the indoor evaluation of drilling fluid related performance. The present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com