A method and device for deoxidation alloying with silicon oxide-containing materials

A deoxidation alloying technology containing silicon oxide, which is applied in the field of deoxidation alloying, can solve the problems of poor technical and economic benefits, and achieve the effects of zero emission, convenient operation, and simple device configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

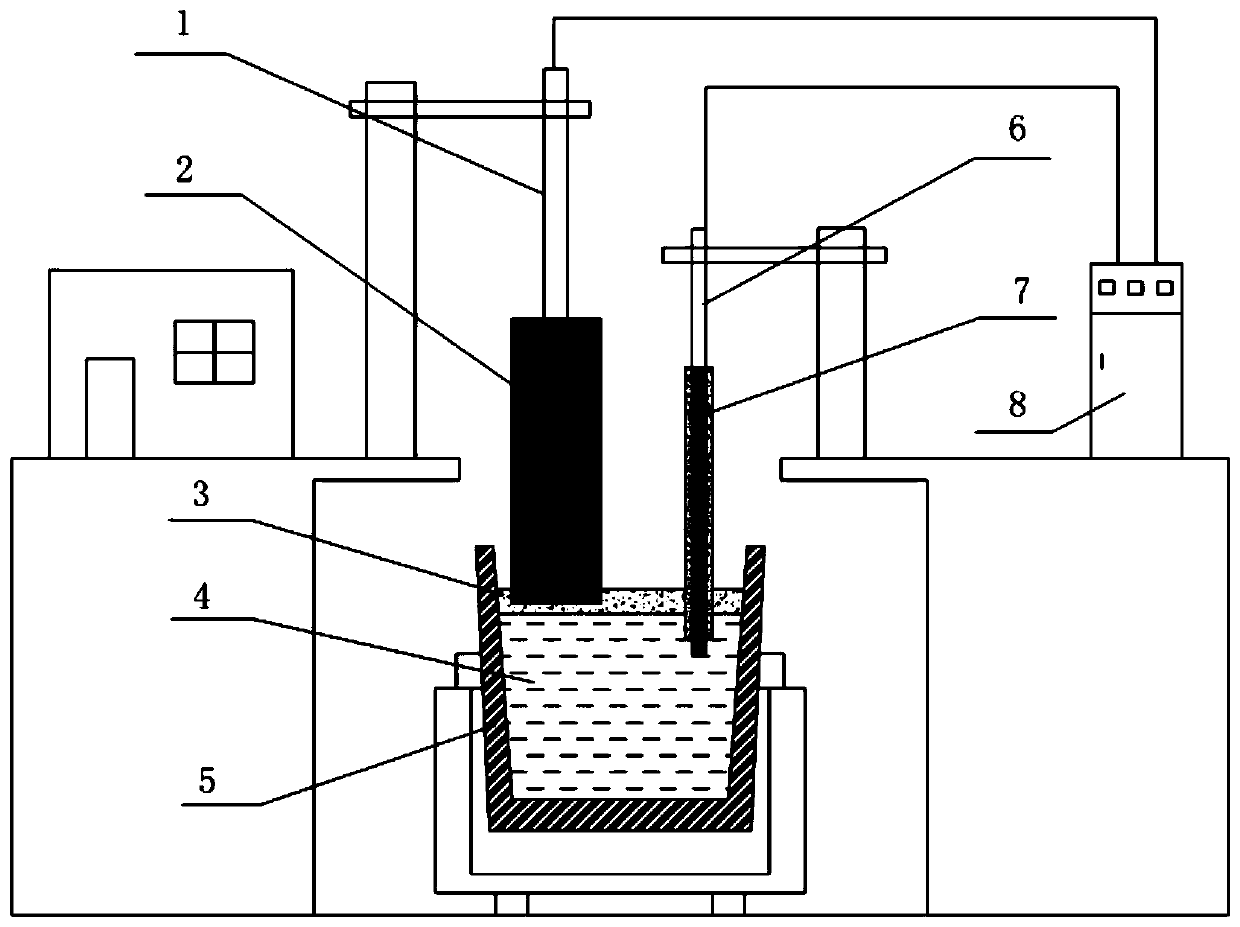

[0050] see figure 1 , The electrolytic reaction control device includes an anode lifting device 1 , an anode 2 , a ladle 5 , a cathode lifting device 6 , a cathode 7 and a DC power supply control device 8 . An anode lifting device 1 is arranged on the upper left side of the ladle 5; the anode lifting device 1 is equipped with high-temperature resistant metal molybdenum ceramic anodes 2, the number is 4, and the anodes 2 are inserted in the slag 3; 2. Adjust the depth of inserting the slag 3 to ensure that the anode 2 is in contact with the slag 3 and not with the molten steel 4; the other side above the ladle 5 is provided with a cathode lifting device 6, and the cathode 7 is installed on the cathode lifting device 6. The cathode 7 is a cylinder with two layers of composite structure inside and outside, the outer layer is wrapped with high temperature resistant cement, and the inside is a graphite rod; the cathode 7 is inserted into the molten steel 4; the cathode lifting devi...

Embodiment 2

[0062] The special electrolytic reaction control device of this embodiment is the same as that of Embodiment 1.

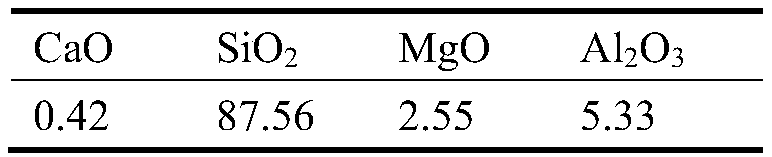

[0063] The silicon oxide-containing material used in this embodiment is wollastonite, and its composition is as shown in Table 3;

[0064] Table 3 main chemical composition of wollastonite wt%

[0065]

[0066] Apply this special electrolytic reaction control on 100t ladle for deoxidation alloying operation. The overall control process is: the weight of molten steel in the converter is 101 tons, the C content at the end of smelting is 0.071%, the oxygen content at the end of molten steel is 0.035% (percentage by weight), the temperature of molten steel at the end of smelting is 1697°C; Add wollastonite to molten steel; the amount of wollastonite added is 8Kg / ton of steel; due to the CaO / SiO in wollastonite 2 =0.9, meet the requirements, then no need to add small grains of white ash.

[0067] The electrolytic reaction control device is used to apply an electri...

Embodiment 3

[0069] The special electrolytic reaction control device of this embodiment is the same as that of Embodiment 1.

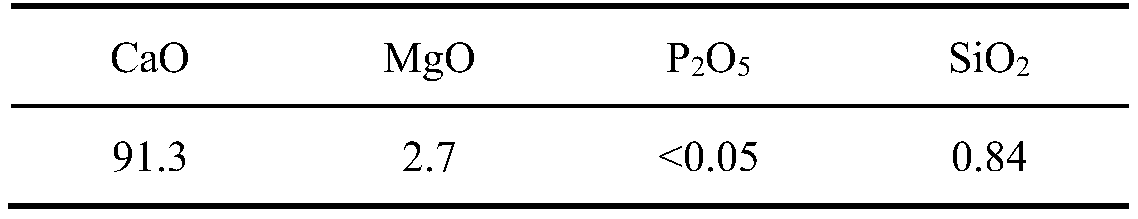

[0070] The silicon oxide-containing material used in this embodiment is high slag, and its composition is as shown in Table 4;

[0071] Table 4 Main chemical composition of high slag wt%

[0072]

[0073] Apply this special electrolytic reaction control on 100t ladle for deoxidation alloying operation. The overall control process is: the weight of molten steel in the converter is 103 tons, the C content at the end of smelting is 0.064%, the oxygen content at the end of molten steel is 0.045% (percentage by weight), the temperature of molten steel at the end of smelting is 1707°C; Add high slag to the molten steel in the middle, the addition amount is 15Kg / ton of steel; due to the high slag CaO / SiO 2 = 1.1, meet the requirements, then no need to add small grains of white ash.

[0074] The electrolytic reaction control device is used to apply an electric field ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com