Preparation method of silk paper doped with cellulose nano whiskers and its application in facial mask

A nano-whisker and cellulose technology, applied in the directions of synthetic cellulose fibers, preparations for skin care, paper, etc., can solve the problems of poor utilization of essence and limited ability to absorb active ingredients, and achieve no side effects and adverse effects. effect, good water holding capacity, good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

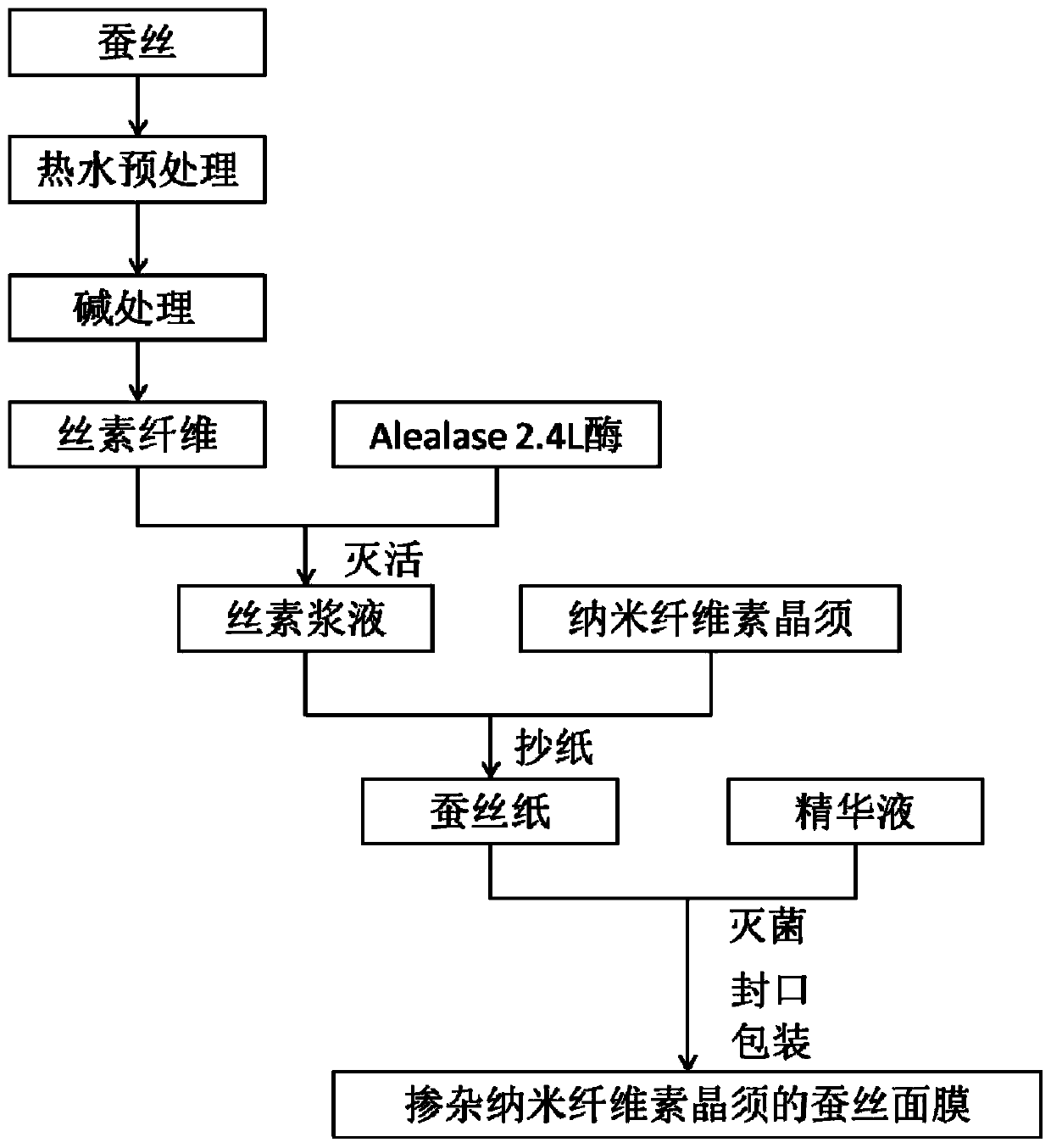

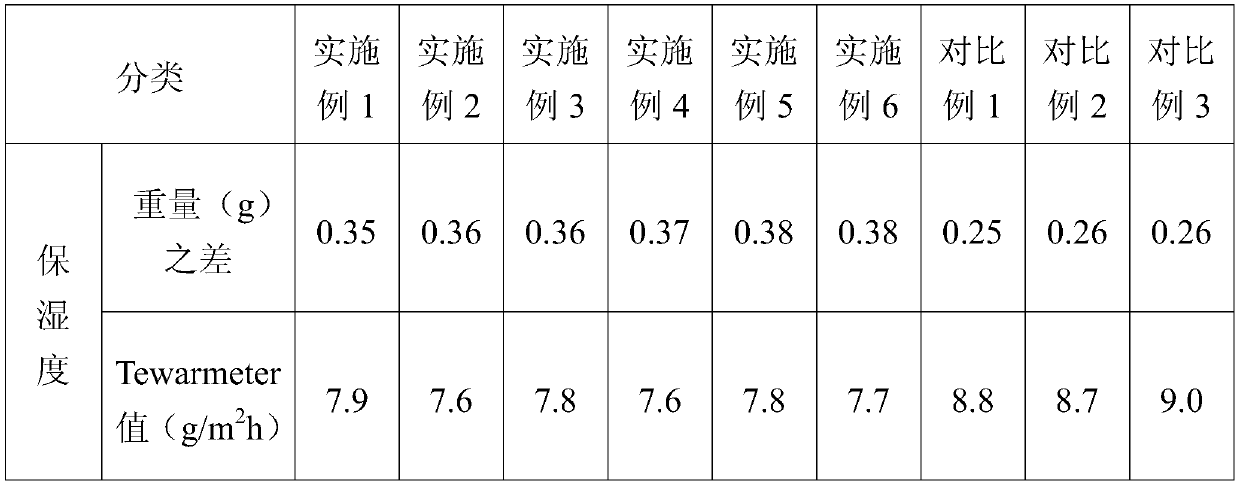

Method used

Image

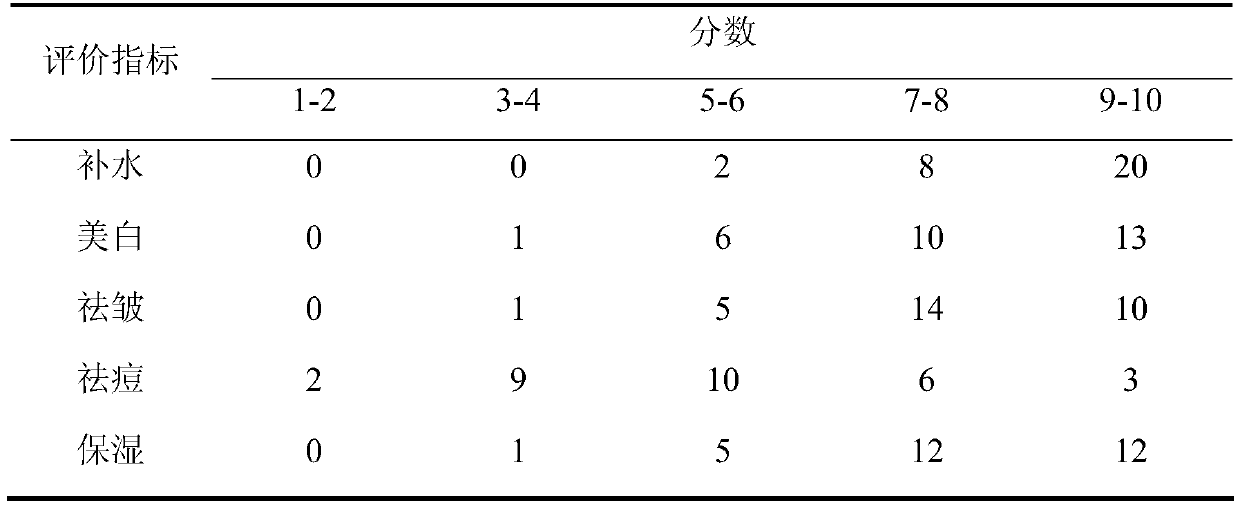

Examples

Embodiment 1

[0044] A silk mask doped with cellulose nano whiskers, the preparation method of which is as follows:

[0045] (1) The silk raw material was added into water at 95°C for 1 hour, the mass ratio of silk to deionized water was 1:1, and alkali treatment was performed after centrifugal dehydration. The centrifugation is carried out with a flat plate centrifuge, and the centrifugation conditions are as follows: the rotating speed is 3000rpm, and the centrifugation time is 15min. The alkali treatment is specifically: immersing the silk in 80° C. with a mass fraction of 0.1% Na 2 CO 3 In the solution, after reacting for 30 minutes, wash it with 80°C deionized water, and then add 80°C, 0.1% Na 2 CO 3In the solution, react for 30 minutes, repeat once, and wash the obtained silk fiber until it is neutral; wherein the mass ratio of silk to sodium carbonate is 100:1.

[0046] (2) Mix Alealase 2.4L enzyme into the silk fiber obtained in step (1), stir and disperse evenly at a rotating s...

Embodiment 2

[0049] A kind of silk mask containing cellulose nano whiskers, its preparation method is as follows:

[0050] (1) Add silk raw materials into water at 95°C for 3 hours, the mass ratio of silk to deionized water is 1:100, and carry out alkali treatment after centrifugal dehydration. The centrifugation conditions are as follows: the rotation speed is 3000 rpm, and the centrifugation time is 15 minutes. The alkali treatment is specifically: soaking the silk at 85°C with a mass fraction of 10% Na 2 CO 3 In the solution, after reacting for 60 minutes, wash it with 85°C deionized water, and then add 10% Na at 85°C again. 2 CO 3 In the solution, react for 60 minutes, repeat the execution 5 times, and wash the obtained silk fibroin fiber to neutrality. Wherein the mass ratio of silk and sodium carbonate is 100:10.

[0051] (2) Mix Alealase 2.4L enzyme into the silk fiber obtained in step (1), stir and disperse evenly at a rotating speed of 200r / min, and add enzyme at a temperatur...

Embodiment 3

[0054] A kind of silk mask containing cellulose nano whiskers, its preparation method is as follows:

[0055] (1) Add silk raw materials into water at 100°C for 3 hours, the mass ratio of silk to deionized water is 1:50, and carry out alkali treatment after centrifugal dehydration. The centrifugation conditions are as follows: the rotation speed is 3000 rpm, and the centrifugation time is 15 minutes. The alkali treatment is specifically: soaking silk at 90°C with a mass fraction of 5% Na 2 CO 3 In the solution, after reacting for 40 minutes, wash it with 90°C deionized water, and then add 90°C, 5% Na 2 CO 3 In the solution, react for 40 minutes, repeat the execution 10 times, and wash the obtained silk fiber to neutrality; wherein the mass ratio of silk to sodium carbonate is 100:5.

[0056] (2) Mix Alealase 2.4L enzyme into the silk fiber obtained in step (1), stir and disperse evenly at a rotating speed of 1000r / min, and add enzyme at a temperature of 70°C with an enzyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com