LED chip and manufacturing method thereof

A technology of LED chips and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost and increase the amount of light output, and achieve the effects of high cost, reduced manufacturing cost, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

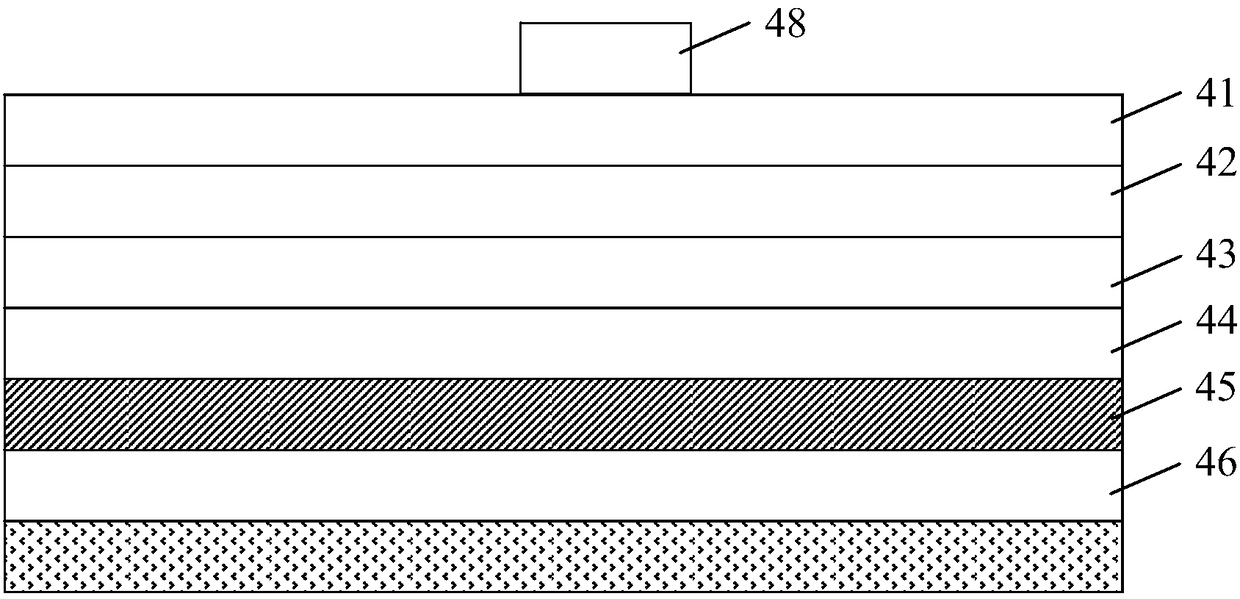

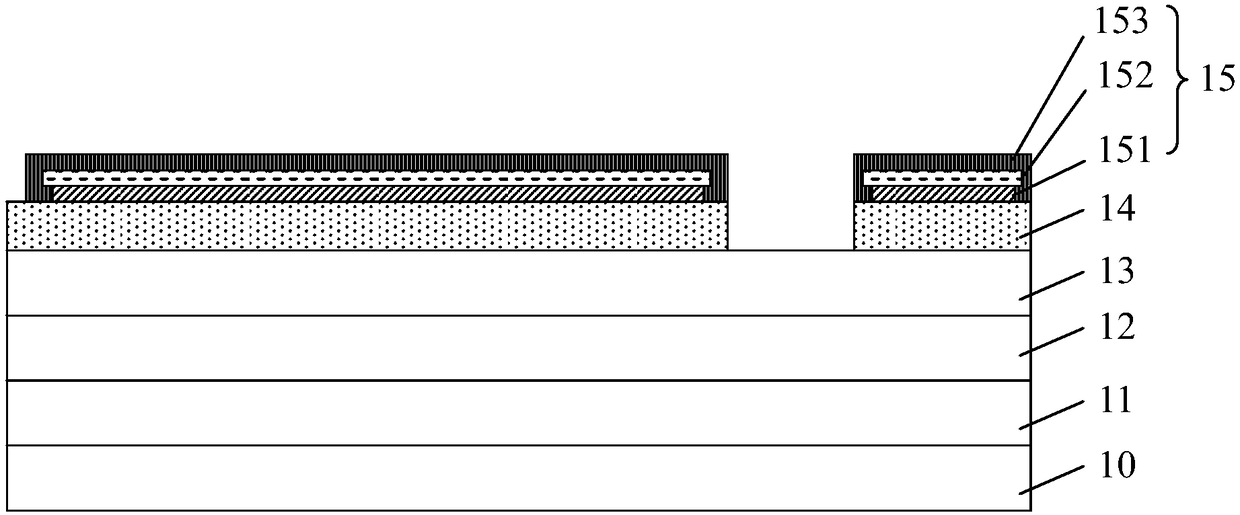

[0048] The invention provides an LED chip and a manufacturing method thereof. The structure of Ag-TiW-Ti (silver-titanium tungsten-titanium) is used in the reflective layer of the LED chip, and the protection of the silver layer is realized by two metals, titanium tungsten and titanium. Prevents silver leaching and flow, and highly adherent metal enables adhesion to subsequent films. The reflective layer metal structure described in the present invention is suitable for LED chips with flip-chip structure or vertical structure.

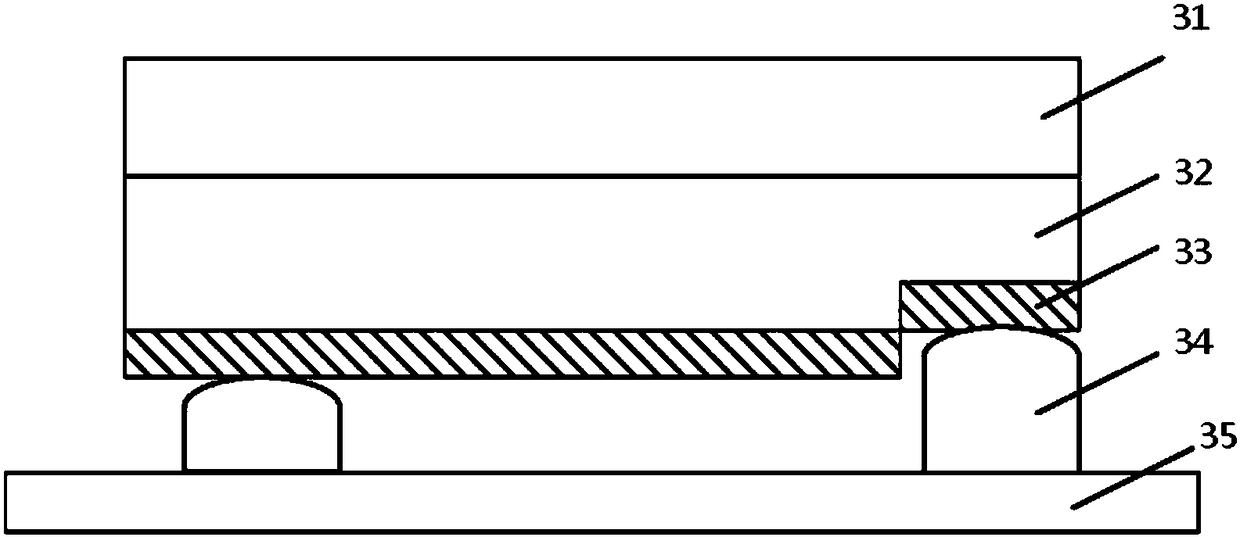

[0049] like Figure 3 ~ Figure 6As shown, the LED chip with flip-chip structure and its manufacturing method include the following processes:

[0050] like image 3 As shown, a front-end structure is provided, including a sapphire substrate 10, and an N-GaN layer 11, a quantum well layer 12, and a P- GaN layer 13.

[0051] Form the ohmic contact layer 14 on the surface of the front-end structure, and pattern it to expose the P-GaN layer 13; the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com