Novel high-nickel ternary anode material and preparation

A positive electrode material and high-nickel technology, which is applied in the field of new high-nickel ternary positive electrode materials and their preparation, can solve the problems of difficult mining, low specific capacity, and increased material production costs, and achieve good thermal and electrochemical stability , Excellent cycle stability and rate performance, low degree of cation mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

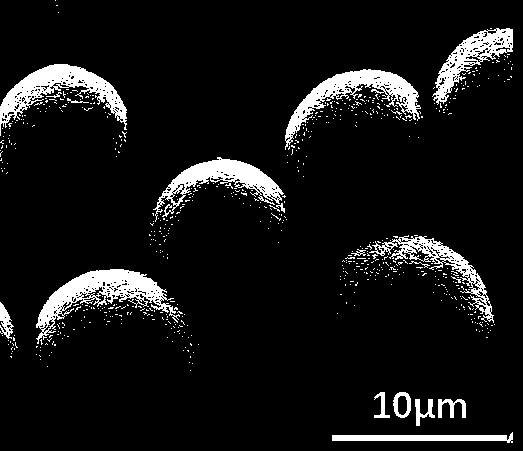

[0035] Example 1 The preparation of a novel high-nickel ternary positive electrode material comprises the following steps:

[0036] S1. Preparation of precursor by co-precipitation method: Weigh analytically pure nickel sulfate, cobalt sulfate, and manganese sulfate according to the stoichiometric ratio of the target sample and dissolve them in deionized water as a reaction feed solution for later use; take the corresponding amount of NaOH and dissolve them in deionized water As a precipitant for standby; use a four-necked flask as a reaction vessel, add a certain amount of deionized water into the four-necked flask as the reaction bottom liquid, seal the four-necked flask before the reaction starts, and pass argon gas into the bottle for a period of time , get rid of the oxygen in the reaction system; when the reaction starts, add an appropriate amount of ammonia water as a complexing agent in the bottom liquid, and add the reaction feed liquid and the precipitating agent (NaO...

Embodiment 2

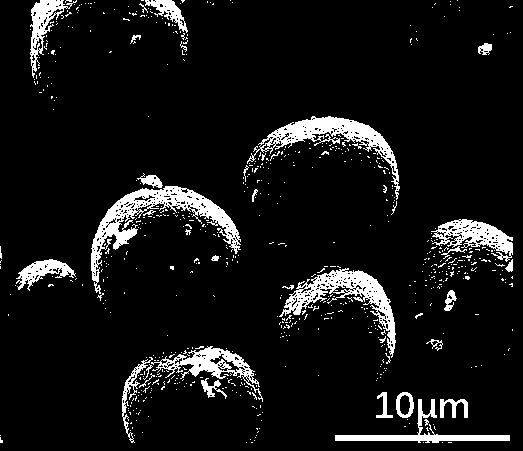

[0039] Example 2 The preparation of a novel high-nickel ternary positive electrode material comprises the following steps:

[0040] S1. Preparation of precursor by co-precipitation method: Weigh analytically pure nickel sulfate, cobalt sulfate, and manganese sulfate according to the stoichiometric ratio of the target sample and dissolve them in deionized water as a reaction feed solution for later use; take the corresponding amount of NaOH and dissolve them in deionized water As a precipitant for standby; use a four-necked flask as a reaction vessel, add a certain amount of deionized water into the four-necked flask as the reaction bottom liquid, seal the four-necked flask before the reaction starts, and pass argon gas into the bottle for a period of time , get rid of the oxygen in the reaction system; when the reaction starts, add an appropriate amount of ammonia water as a complexing agent in the bottom liquid, and add the reaction feed liquid and the precipitating agent (NaO...

Embodiment 3

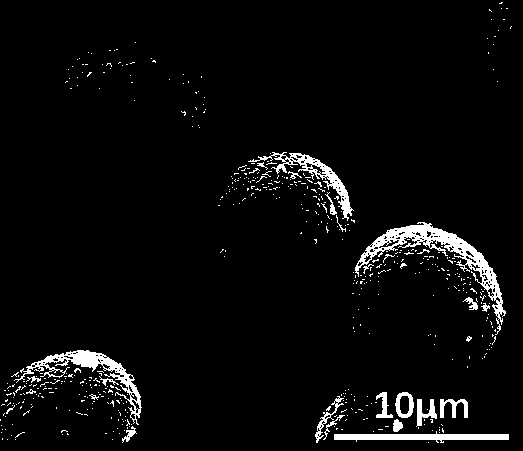

[0043] Example 3 The preparation of a novel high-nickel ternary positive electrode material comprises the following steps:

[0044] S1. Preparation of precursor by co-precipitation method: Weigh analytically pure nickel sulfate, cobalt sulfate, and manganese sulfate according to the stoichiometric ratio of the target sample and dissolve them in deionized water as a reaction feed solution for later use; take the corresponding amount of NaOH and dissolve them in deionized water As a precipitant for standby; use a four-necked flask as a reaction vessel, add a certain amount of deionized water into the four-necked flask as the reaction bottom liquid, seal the four-necked flask before the reaction starts, and pass argon gas into the bottle for a period of time , get rid of the oxygen in the reaction system; when the reaction starts, add an appropriate amount of ammonia water as a complexing agent in the bottom liquid, and add the reaction feed liquid and the precipitating agent (NaO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com