Honeycomb electrode material and preparation method thereof

An electrode material and honeycomb technology, which is applied in the field of honeycomb electrode material and its preparation, can solve the problems of high overpotential and poor cycle stability of lithium-oxygen batteries, and can solve the problem of overpotential and poor cycle performance, promote hydrothermal reaction, The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

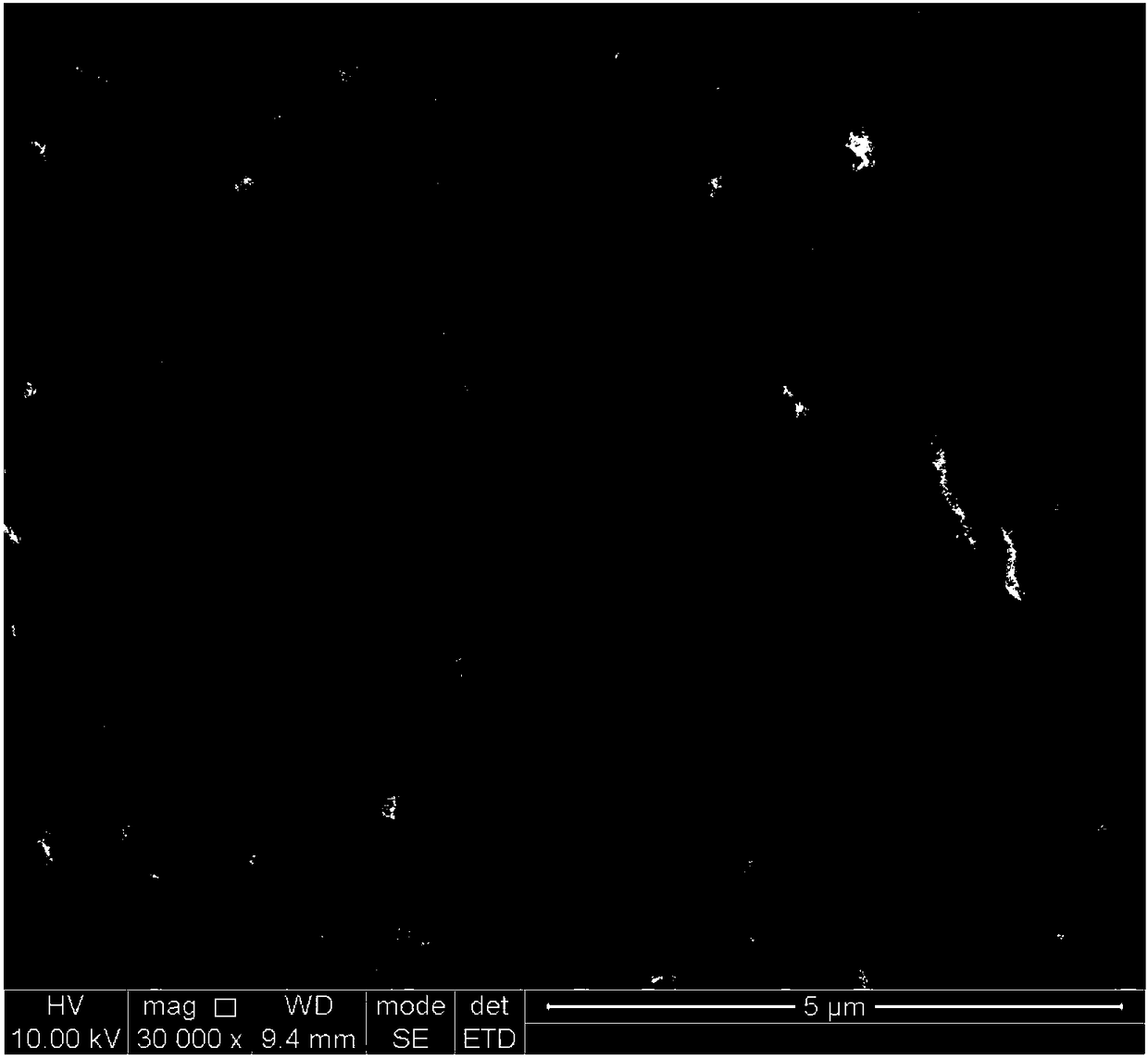

[0028] A kind of cellular electrode material of the present invention is prepared by the following method:

[0029] 1) Preparation of the first solution: Mix 10ml of nickel chloride hexahydrate with 20ml of ethylene glycol, then mix 5ml of thioacetamide with 15ml of deionized water, and then mix the above two mixed solutions to obtain the first solution;

[0030] 2) adding urea to the first solution to obtain the second solution;

[0031] 3) The second solution is subjected to a hydrothermal reaction at 160° C., and the hydrothermal reaction time is 32 hours;

[0032] 4) After the hydrothermal reaction is completed, rinse with deionized water for 3 times, and then dry in a vacuum drying oven.

Embodiment 2

[0034] A kind of cellular electrode material of the present invention is prepared by the following method:

[0035] 1) Preparation of the first solution: Mix 10ml of nickel chloride hexahydrate with 20ml of ethylene glycol, then mix 5ml of thioacetamide with 15ml of deionized water, and then mix the above two mixed solutions to obtain the first solution;

[0036] 2) adding urea to the first solution to obtain the second solution;

[0037] 3) The second solution is subjected to a hydrothermal reaction at 180° C., and the hydrothermal reaction time is 25 hours;

[0038] 4) After the hydrothermal reaction is completed, rinse with absolute ethanol for 4 times, and then dry in a vacuum drying oven.

Embodiment 3

[0040] A kind of cellular electrode material of the present invention is prepared by the following method:

[0041] 1) Preparation of the first solution: Mix 10ml of nickel chloride hexahydrate with 20ml of ethylene glycol, then mix 5ml of thioacetamide with 15ml of deionized water, and then mix the above two mixed solutions to obtain the first solution;

[0042] 2) adding urea to the first solution to obtain the second solution;

[0043] 3) The second solution is subjected to a hydrothermal reaction at 200° C., and the hydrothermal reaction time is 16 hours;

[0044] 4) After the hydrothermal reaction is completed, rinse with deionized water for 5 times, and then dry in a vacuum drying oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com