Anti-soldering agent coating method

A solder stop and coating technology, applied in the field of superplastic forming and diffusion joining, can solve the problems of higher than 0.1mm, even requiring tens of microns, and cannot well meet the high precision requirements of the solder mask interface. The effect of coating accuracy and ensuring coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

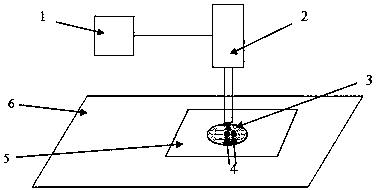

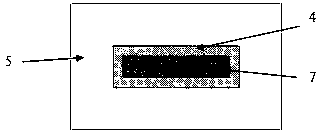

[0029] Such as figure 1 As shown in Fig. 1, a coating method of solder stopper adopts laser selective cladding technology and is designed according to actual needs and controlled by computer programming. Specifically: the first step is to spread a layer of solder stopper powder 3 on the surface of the test piece 5, and the thickness of the solder stopper powder 3 is controlled by adjusting the position of the scraper and the lifting table 6; the second step is to place the test piece 5 The position, shape and size data of the solder stop coating target area 4 designed above are imported into the computer software, and the laser movement trajectory planning of the solder stop coating area is realized through software program programming. The software program can be the software program in the prior art. ; The third step is to set the working parameters of the laser 2 according to the actual needs, and control the laser 2 to move according to the predetermined track through the ...

Embodiment 2

[0031] Such as Figure 1-2 As shown in Fig. 1, a coating method of solder stopper adopts laser selective cladding technology and is designed according to actual needs and controlled by computer programming. Specifically: the first step is to spread a layer of solder stop powder 3 on the surface of the test piece 5. The surface of the test piece 5 includes the position of the target coating area 4 for diffusion connection. The thickness of the solder stop powder 3 is adjusted by adjusting the scraper and lifting The position of platform 6 is controlled, and the solder stop powder 3 is epoxy resin powder and yttrium oxide powder mixed and stirred evenly, and the thickness of each layer of solder stop powder 3 is less than 100 microns; in the second step, design the test piece 5 Import the position, shape and size data of the solder stop target coating area 4 into the computer software, and realize the laser 2 movement track planning in the solder stop coating area through softwa...

Embodiment 3

[0033] Such as Figure 1-2 As shown in Fig. 1, a coating method of solder stopper adopts laser selective cladding technology and is designed according to actual needs and controlled by computer programming. Specifically: the first step is to spread a layer of solder stop powder 3 on the surface of the test piece 5. The surface of the test piece 5 includes the position of the target coating area 4 for diffusion connection. The thickness of the solder stop powder 3 is adjusted by adjusting the scraper and lifting The position of platform 6 is controlled, and the solder stop powder 3 is epoxy resin powder and yttrium oxide powder mixed and stirred evenly, and the thickness of each layer of solder stop powder 3 is less than 100 microns; in the second step, design the test piece 5 Import the position, shape and size data of the solder stop target coating area 4 into the computer software, and realize the laser 2 movement track planning in the solder stop coating area through softwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com