Lightweight fiber cement tile and preparation method thereof

A lightweight fiber and cement tile technology, applied in the field of construction industry, can solve the problems of heavy tile weight, unfavorable transportation and construction, etc., and achieve the effect of reducing weight, being beneficial to construction, and saving preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

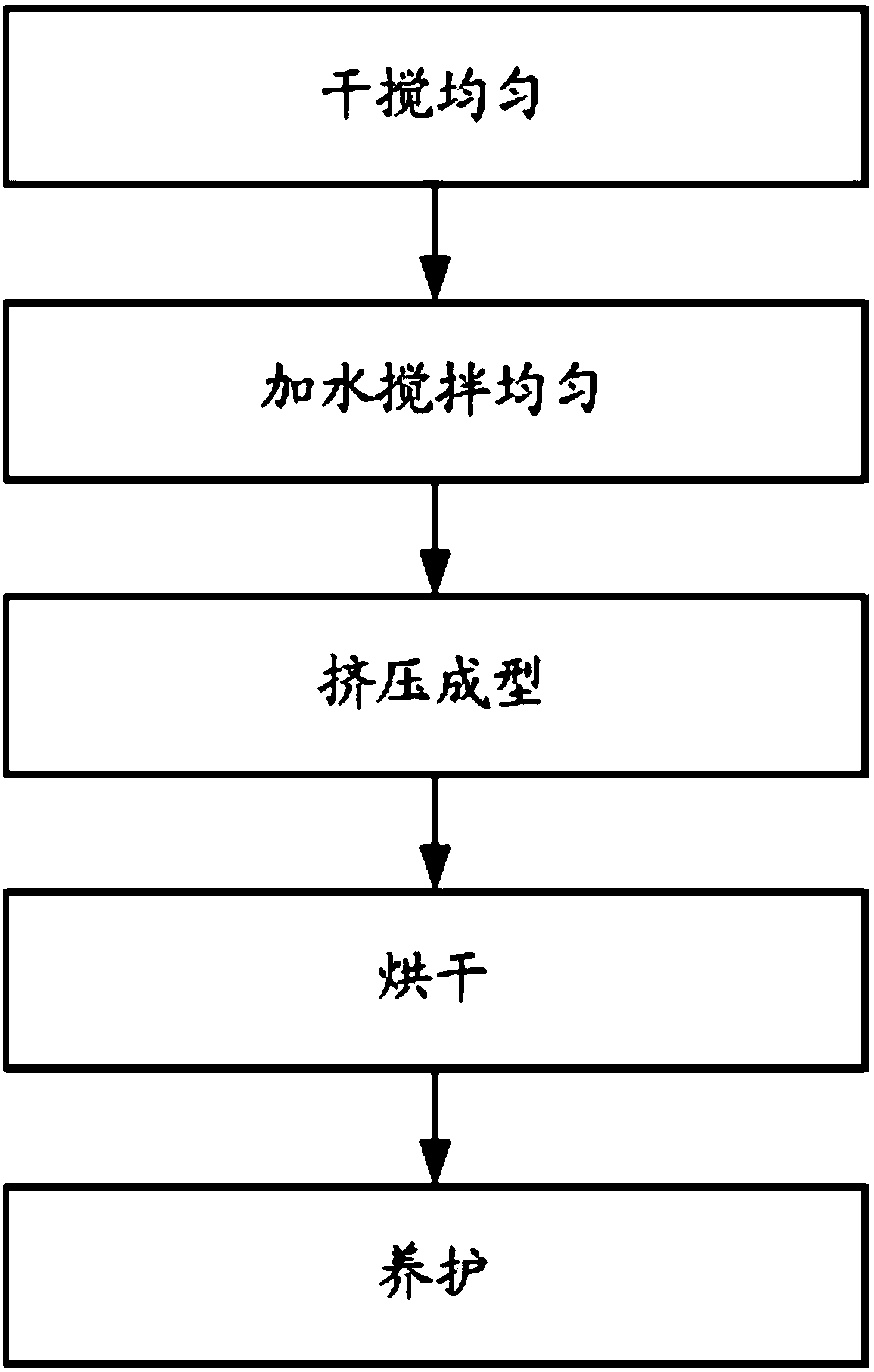

Method used

Image

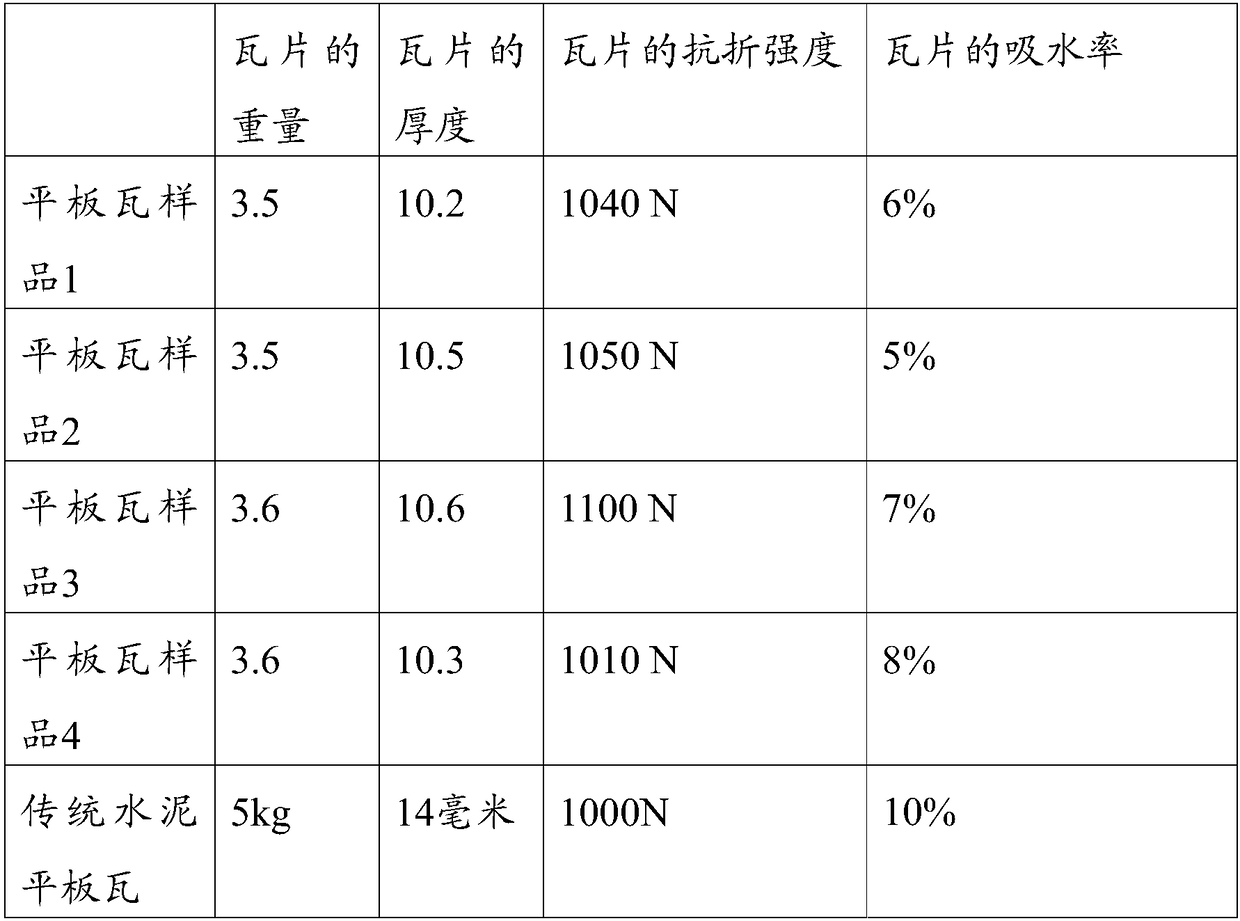

Examples

preparation Embodiment 1

[0025] Components:

[0026] Yellow sand 50 parts by weight

[0027] 40 parts by weight of cement

[0028] Fiber 0.3 parts by weight

[0029] Wherein, in the yellow yarn, the weight ratio of the fine sand is 75 parts by weight; the weight ratio of the medium-coarse sand is 15 parts by weight; and the weight ratio of the coarse sand is 10 parts by weight. The cement is Portland low-alkalinity cement with a strength grade of 42.5 or 52.5. Fiber, using polypropylene with a specific gravity of 0.91-0.92g / cm 3 monofilament fibers.

[0030] Preparation:

[0031] Step 1, weighing the yellow sand, cement and fiber of the formula; adding it into a disperser with a revolution per minute of 1000-1500 rpm and stirring for 90 seconds, so that the yellow sand, cement and fiber are evenly dispersed to obtain a mixed material;

[0032] Step 2, adding water with a mass fraction of 7% to 10% to the mixed material obtained in step 1, and stirring again for 120 seconds to form a flowable mat...

preparation Embodiment 2

[0037] Components:

[0038] 60 parts by weight of yellow sand

[0039] 40 parts by weight of cement

[0040] Fiber 0.5 parts by weight

[0041] Wherein, in the yellow yarn, the weight ratio of the fine sand is 65 parts by weight; the weight ratio of the medium-coarse sand is 25 parts by weight; and the weight ratio of the coarse sand is 10 parts by weight. The cement is Portland low-alkalinity cement with a strength grade of 42.5 or 52.5. Fiber, using polypropylene with a specific gravity of 0.91-0.92g / cm 3 monofilament fibers.

[0042] Preparation:

[0043] Step 1, weighing the yellow sand, cement and fiber of the formula; adding it into a disperser with a revolution per minute of 1000-1500 rpm and stirring for 90 seconds, so that the yellow sand, cement and fiber are evenly dispersed to obtain a mixed material;

[0044] Step 2, adding water with a mass fraction of 10% to the mixed material obtained in step 1, stirring again for 120 seconds to form a flowing material; ...

preparation Embodiment 3

[0049] Components:

[0050] Yellow sand 55 parts by weight

[0051] 45 parts by weight of cement

[0052] Fiber 0.4 parts by weight

[0053] Wherein, in the yellow yarn, the weight ratio of the fine sand is 70 parts by weight; the weight ratio of the medium coarse sand is 25 parts by weight; the weight ratio of the coarse sand is 5 parts by weight. The cement is Portland low-alkalinity cement with a strength grade of 42.5 or 52.5. Fiber, using polypropylene with a specific gravity of 0.91-0.92g / cm 3 monofilament fibers.

[0054] Preparation:

[0055] Step 1, weighing the yellow sand, cement and fiber of the formula; adding it into a disperser with a revolution per minute of 1000-1500 rpm and stirring for 90 seconds, so that the yellow sand, cement and fiber are evenly dispersed to obtain a mixed material;

[0056] Step 2, adding water with a mass fraction of 9% to the mixed material obtained in step 1, stirring again for 120 seconds to form a flowable material;

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com