Seawall anti-wave structure and construction method thereof

A technology of seawalls and wave breakers, which is applied in sea area engineering, jetties, embankments, etc., can solve problems such as lack of protection of seawall surfaces, influence of seawall surface strength, loss of stones and sediment on seawall surfaces, and reduce maintenance cost, ease of maintenance, and the effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

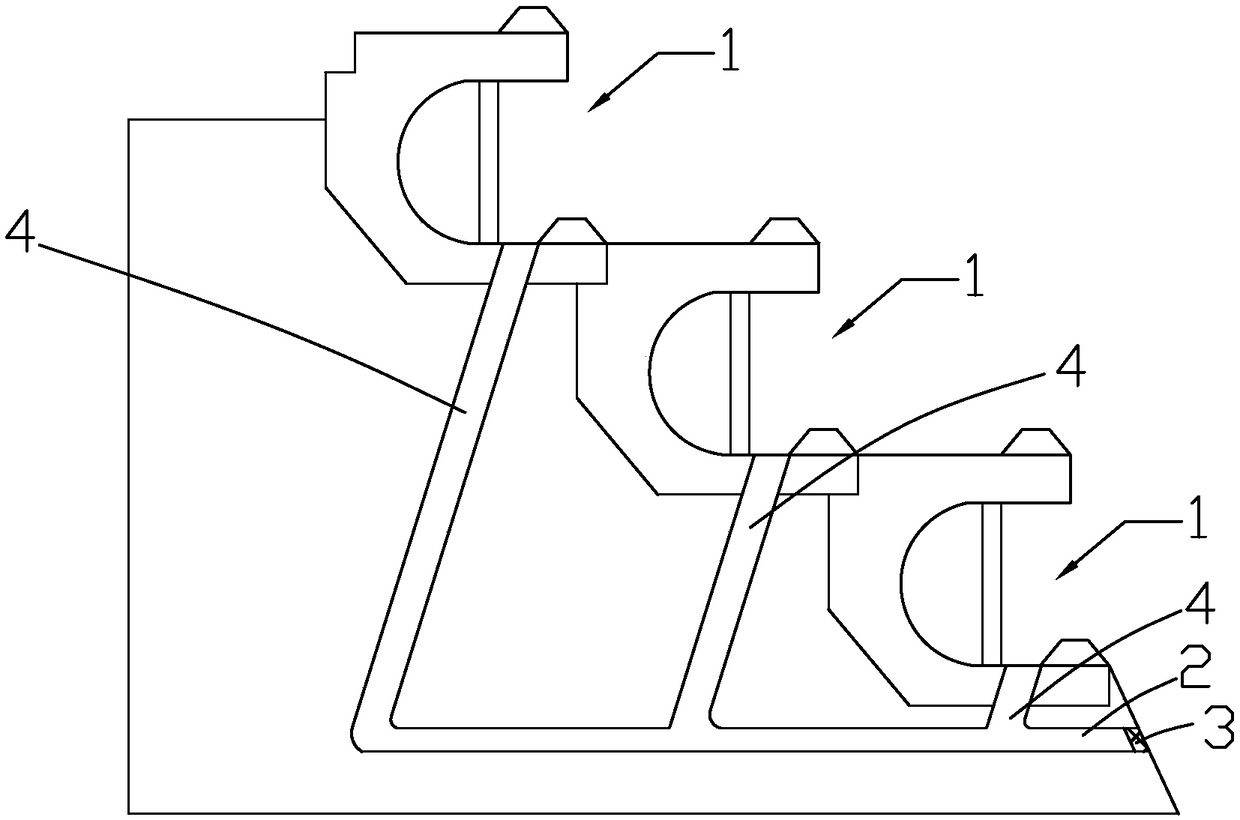

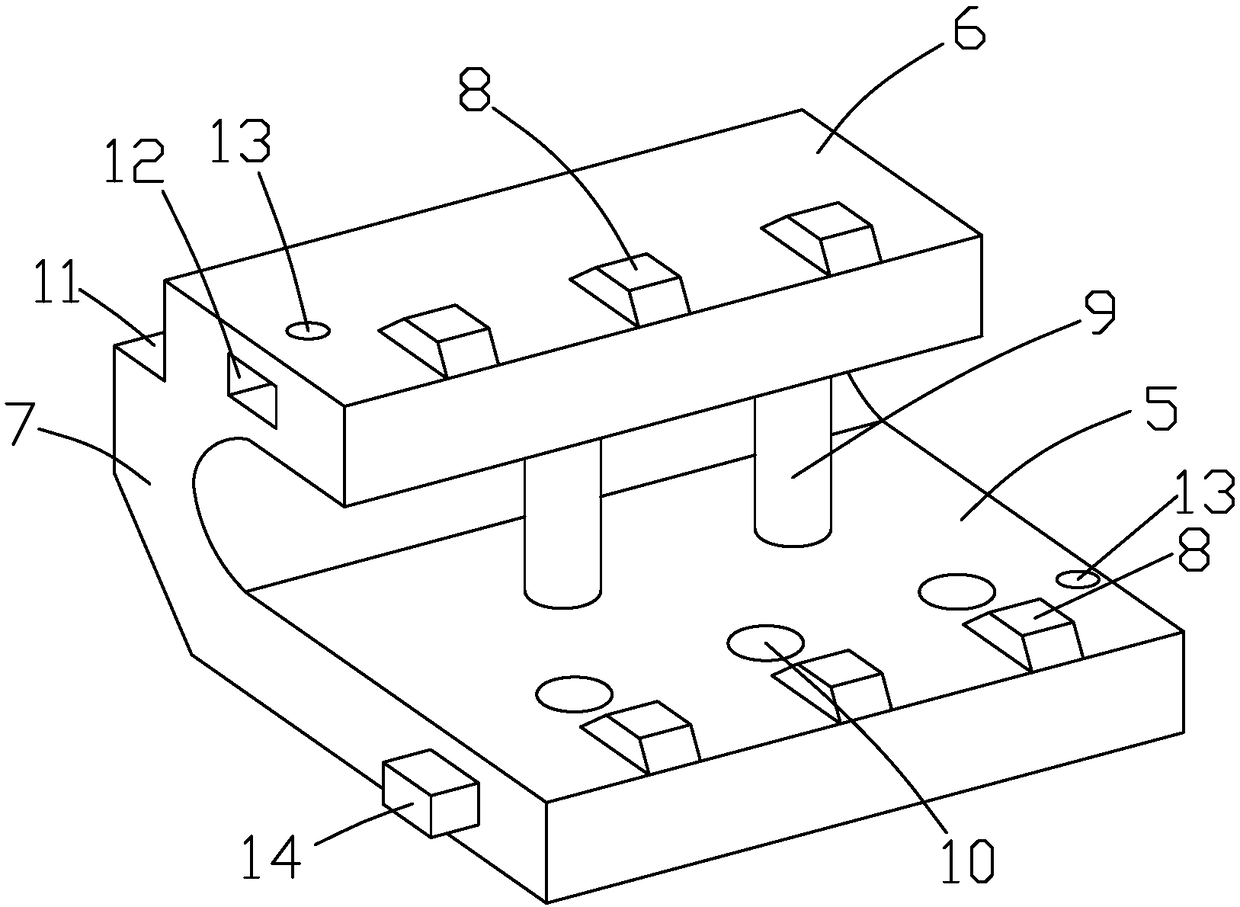

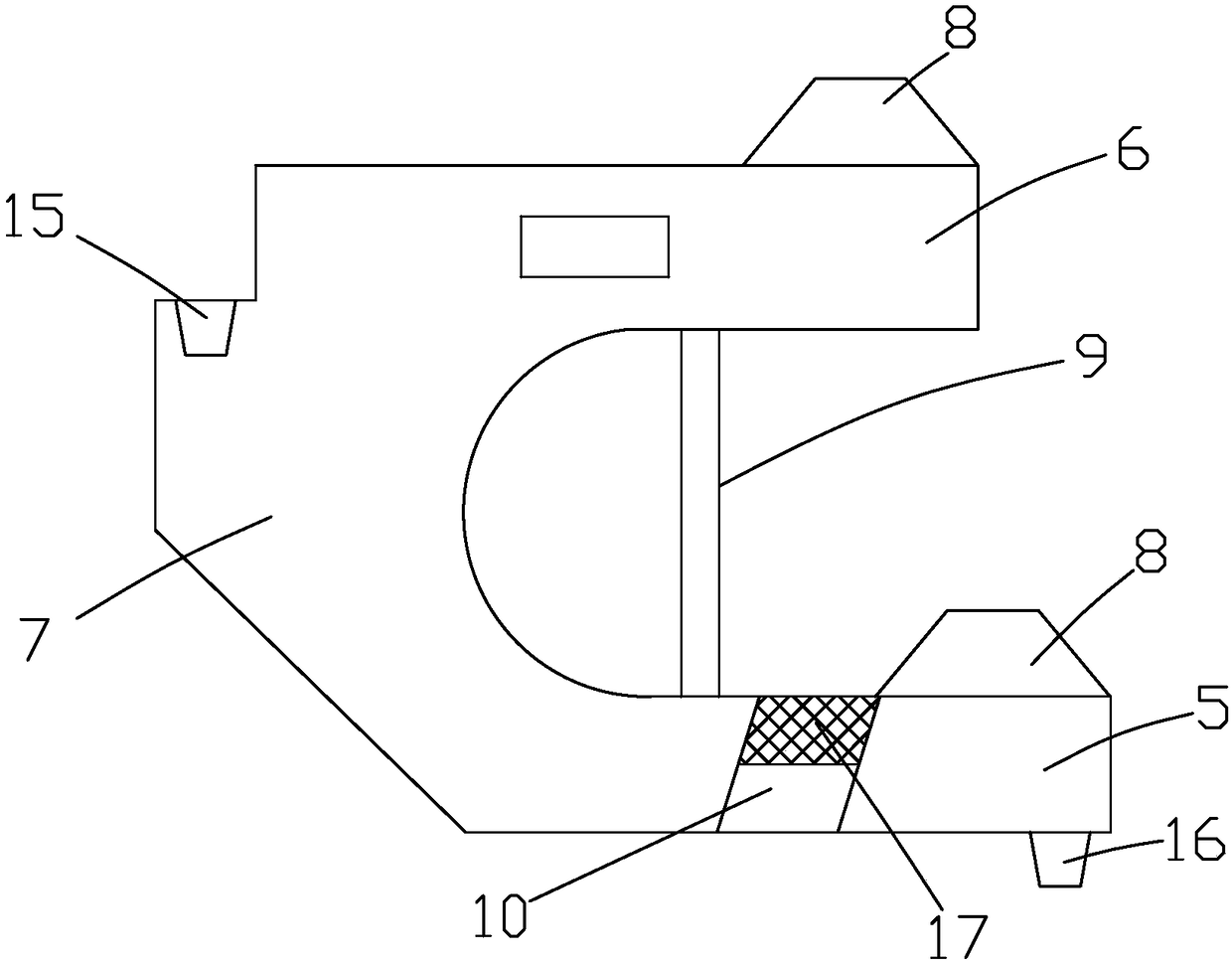

[0045] Such as Figure 1 to Figure 3 As shown, it is a seawall wave-resisting structure of the present invention, comprising a wave-resisting unit 1, a water inlet pipe 2 and a recoil pipe 4, the wave-resisting unit 1 is arranged horizontally and evenly along the seawall surface, and two adjacent left and right The wave-stopping units 1 are fixedly connected by a first limiting mechanism. The first limiting mechanism includes a first limiting hole 12 and a first limiting block 14. The first limiting hole 12 and the first limiting block 14 are respectively Located on both sides of the first wave baffle 5 and the second wave baffle 6, the first limiting block 14 matches the first limiting hole 12, the top surface of the first limiting hole 12 is provided with a bolt hole 13, the first The limiting hole 12 and the first limiting block 14 improve the connection strength between two adjacent wave-stopping units 1 and are convenient for installation and disassembly.

[0046] The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com