Servo real-time measuring device used for rotating blade full-field dynamic deformation and servo real-time measuring method used for rotating blade full-field dynamic deformation

A dynamic deformation and real-time measurement technology, applied in the field of three-dimensional measurement, to achieve the effect of convenient layout, avoiding complicated process and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

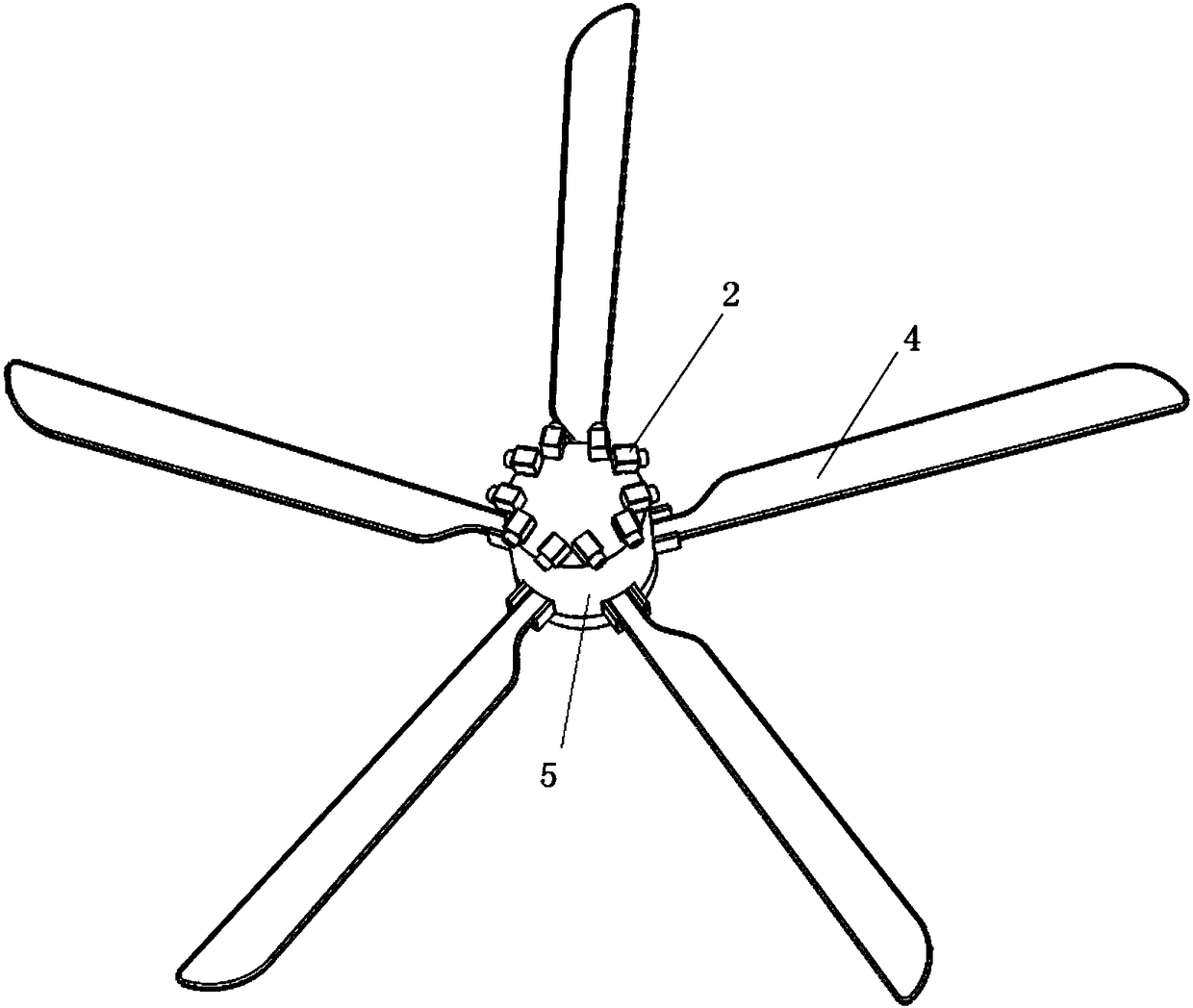

[0037] Such as figure 1 As shown, taking the binocular camera 2 opposite to a blade 4 as an example, the actual situation is as follows figure 1 As shown, the binocular camera 2 and the blade 4 exist in sets.

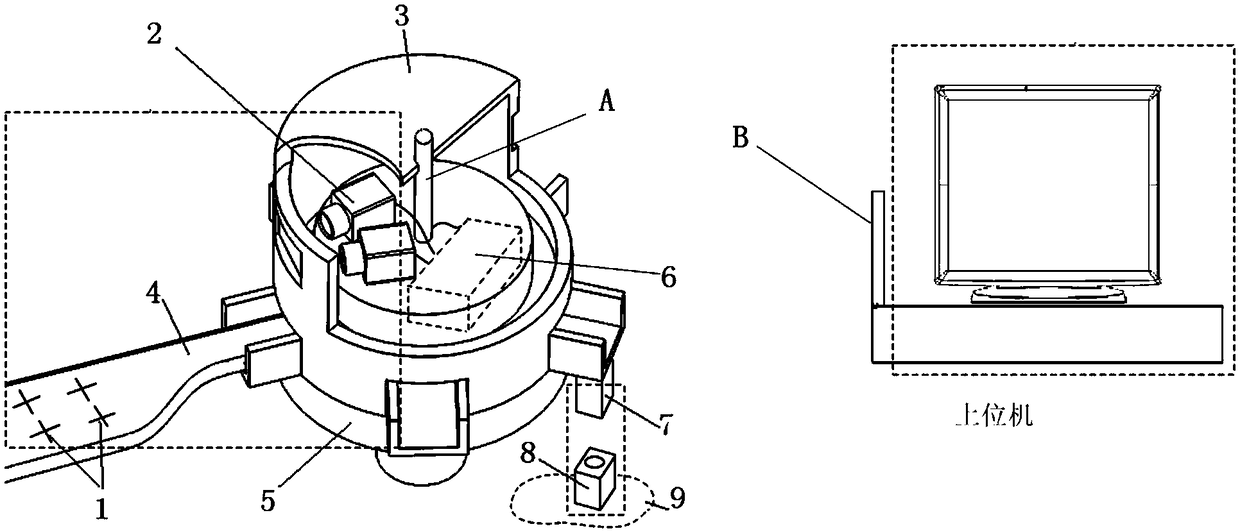

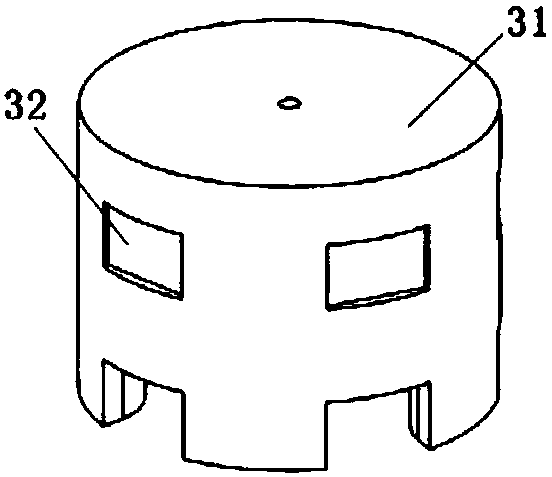

[0038] Such as figure 1 and figure 2 As shown, the present invention proposes a follow-up real-time measuring device for full-field dynamic deformation of rotating blades. The rotor involved includes a hub 5 and a blade 4, and the blade 4 is used as the object to be measured. The measuring device includes Mark point image sensing unit, photoelectric counting unit, real-time data processing unit based on embedded data, data communication unit based on wireless tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com