Silicon thin film material stress detection system

A technology of material stress and detection system, which is applied in the measurement of force, force/torque/power measuring instrument, measuring device, etc. by measuring the change of optical properties of the material when it is stressed, can solve the problem of inability to measure the stress of the sample and the inability to silicon Sample measurement and other issues, to achieve the effect of accurate testing and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

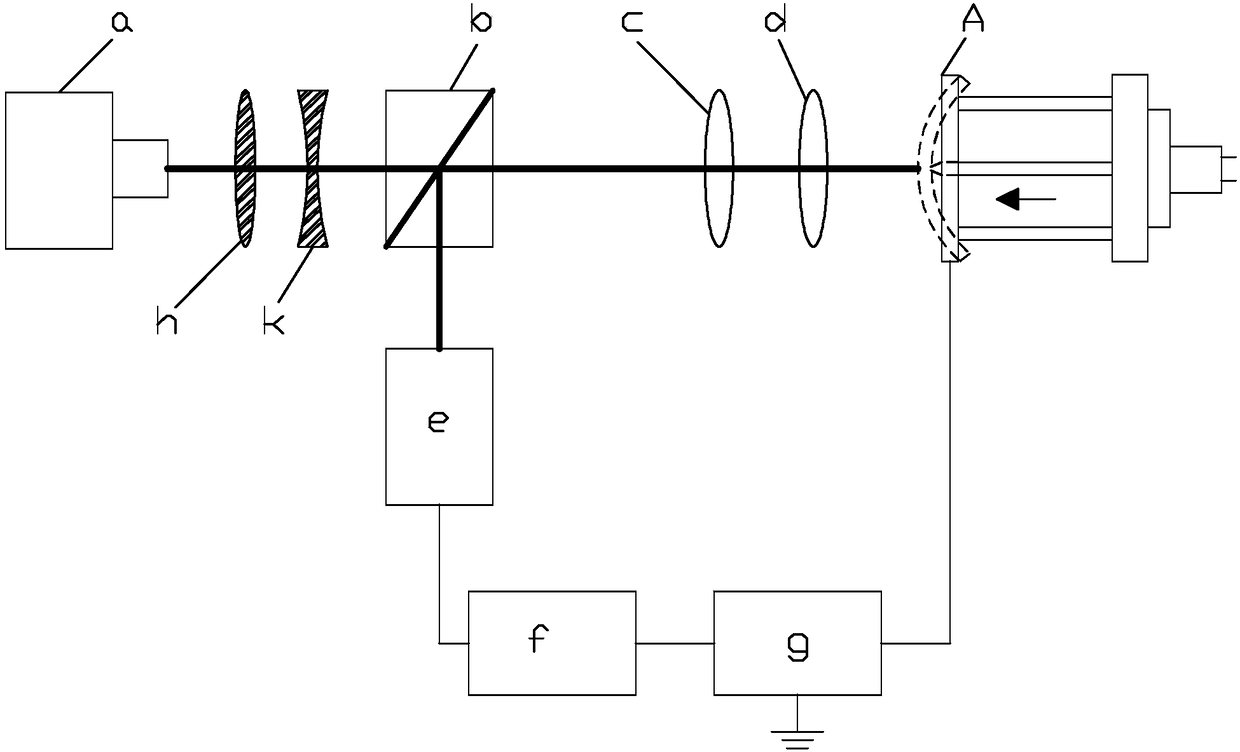

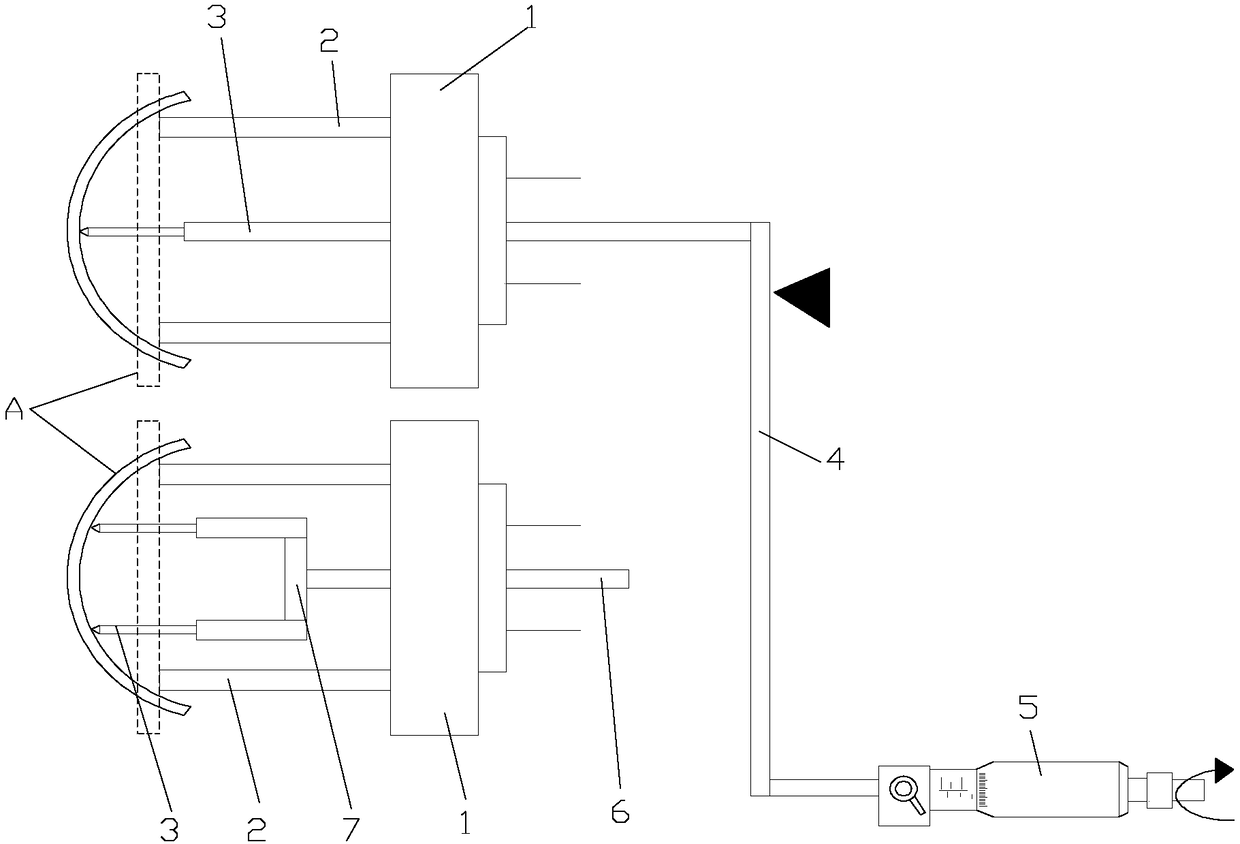

[0026] Such as figure 1 and figure 2 As shown, a kind of silicon film material stress detection system provided in this embodiment, it comprises:

[0027] A laser a is used as a laser beam emitting device. As a preferred solution, a solid-state laser with continuously adjustable output optical power can be used; according to the detection requirements, the wavelength of the laser a emitted beam is 1550nm, and the output optical power is 0-3W Adjustable within the range and the spot is a circular spot with a diameter within 0.8mm;

[0028] Polarizing beam splitter b, which is arranged on the light output side of laser a along the Z-axis direction, is mainly used to convert the output beam of laser a into linearly polarized light that vibrates vert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com