Flexible array substrate, preparation method thereof and flexible display panel

A flexible array and substrate technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of easy breakage of insulating layers and grid lines, and disconnection of display panels, achieving good implementation, saving equipment costs, and guaranteeing The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

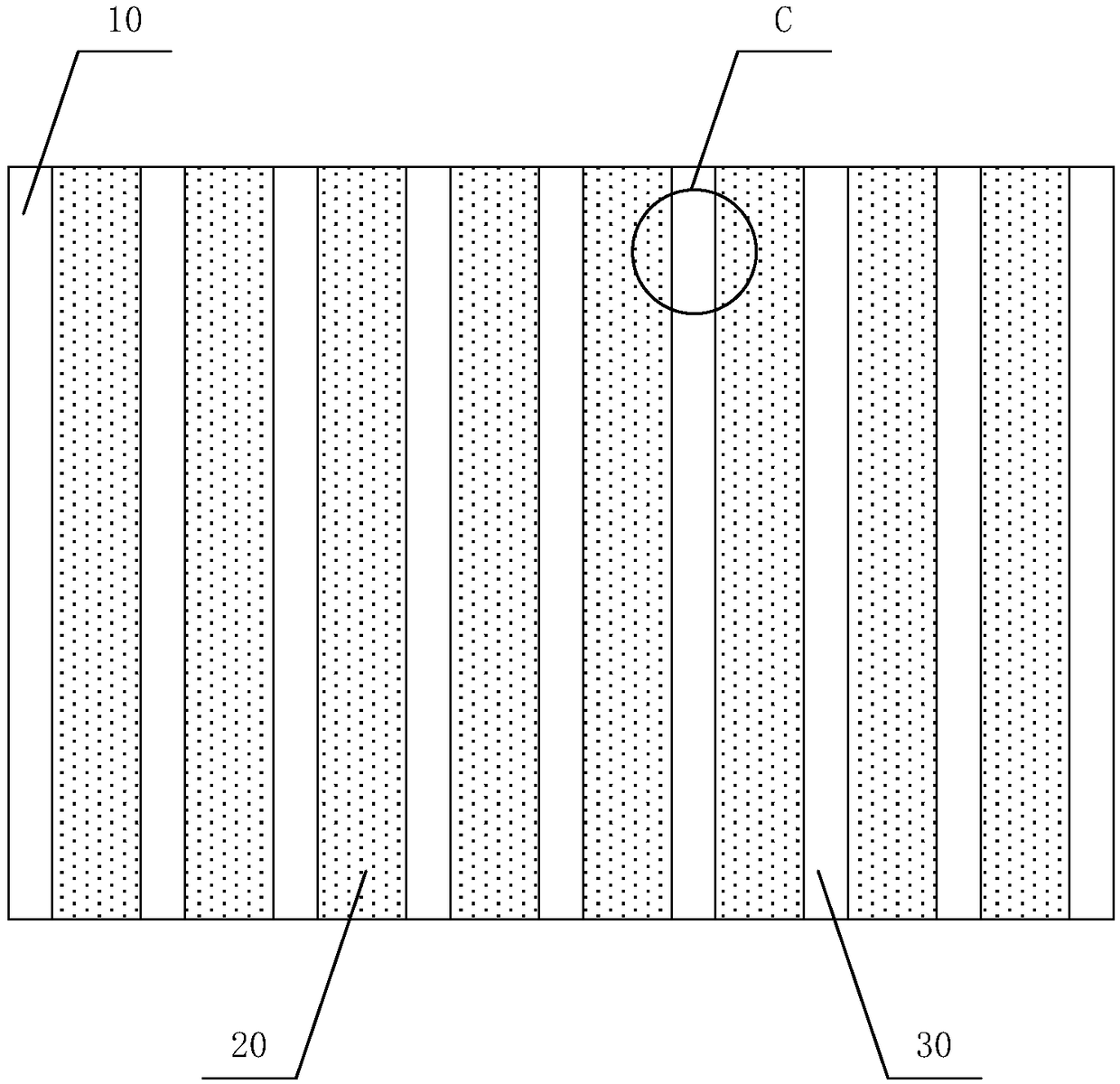

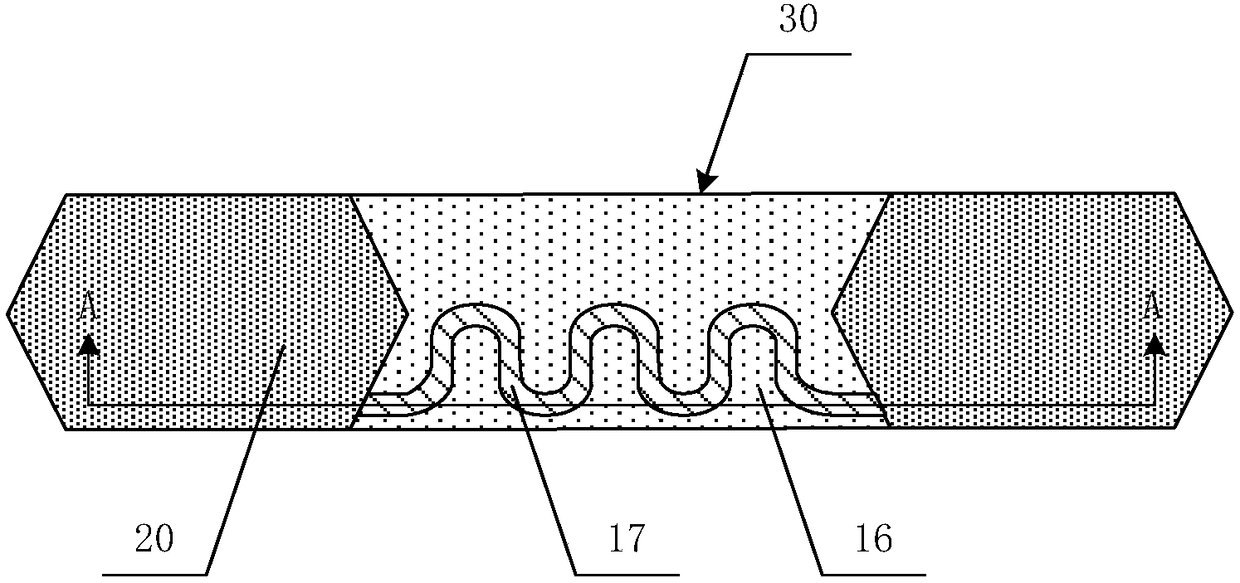

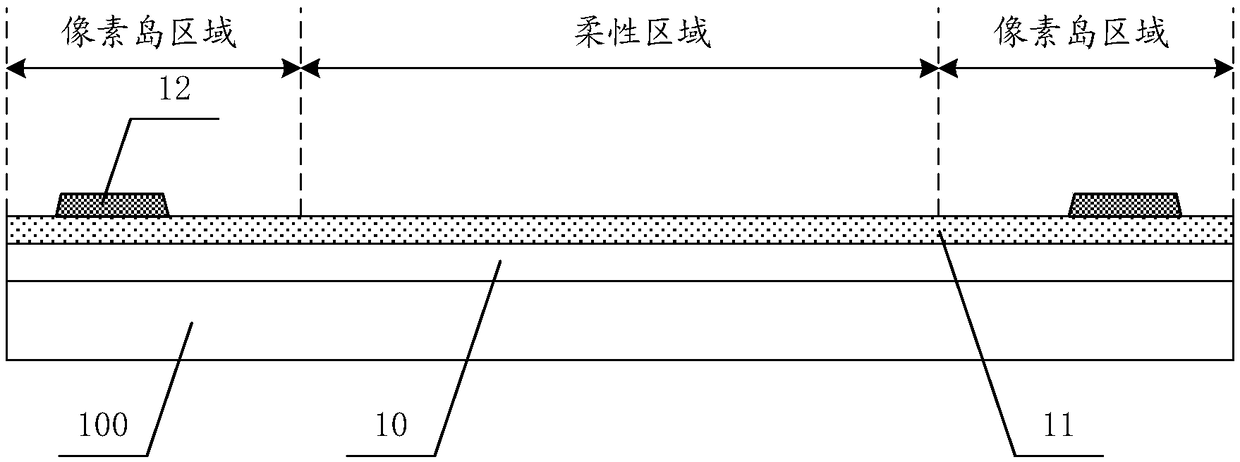

[0061] Figure 3-12 A schematic diagram of preparing a flexible array substrate for the first embodiment of the present invention, all of which are figure 2 Middle A-A sectional view. Among them, the "patterning process" mentioned in this embodiment includes deposition of film layer, coating of photoresist, mask exposure, development, etching, stripping of photoresist, etc., which is an existing mature preparation process. Deposition can use known processes such as sputtering, evaporation, and chemical vapor deposition, coating can use known coating processes, and etching can use known methods, which are not specifically limited here.

[0062] The technical solution of this embodiment will be described in detail below through the preparation process of the flexible array substrate. The overall process of preparing the flexible array substrate in this embodiment is as follows: first, the flexible substrate 10 is formed on the base substrate 100, and then structural layers su...

no. 2 example

[0091] Based on the technical concept of the present invention, an embodiment of the present invention also provides a method for preparing a flexible array substrate. Figure 13 It is a flow chart of the method for preparing the flexible array substrate in this embodiment. Such as Figure 13 Shown, the preparation method of flexible array substrate comprises:

[0092] S1. Forming an active layer, a gate insulating layer, a gate electrode and an interlayer insulating layer in several sequentially arranged pixel island regions;

[0093] S2. Form an elastic layer and connection lines in the flexible area between adjacent pixel island regions, and the connection lines are respectively connected to gate electrodes in adjacent pixel island regions.

[0094] Wherein, step S1 includes:

[0095] S11, sequentially forming an active layer, a gate insulating layer and a gate electrode on the flexible substrate;

[0096] S12. Form an interlayer insulating layer through a patterning pr...

no. 3 example

[0115] This embodiment is an extension based on the first embodiment. The difference from the first embodiment is that in this embodiment, the formation of the elastic layer and the data line pattern is realized by inkjet printing.

[0116] In this embodiment, the process from depositing the buffer layer to forming the pattern of the interlayer insulating layer is the same as that in the first embodiment. Forming the pattern of the elastic layer includes: forming the pattern of the elastic layer with connection grooves on the upper surface in the flexible channel 15b of the flexible area by inkjet printing. Since the inkjet printing method can pre-set the printing thickness of different areas, it is possible to reserve a rectangular or trapezoidal groove in the area where the connecting line pattern is located when printing the elastic layer. Subsequently, the conductive polymer is printed by inkjet printing to form a connection line pattern on the elastic layer, and the condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com