Diffusion method for high-concentration phosphorosilicate glass and high square resistance

A technology of phospho-silicate glass and diffusion method, which is applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., to achieve the effects of increasing the flow rate of the source, reducing the time of the source, and high square resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

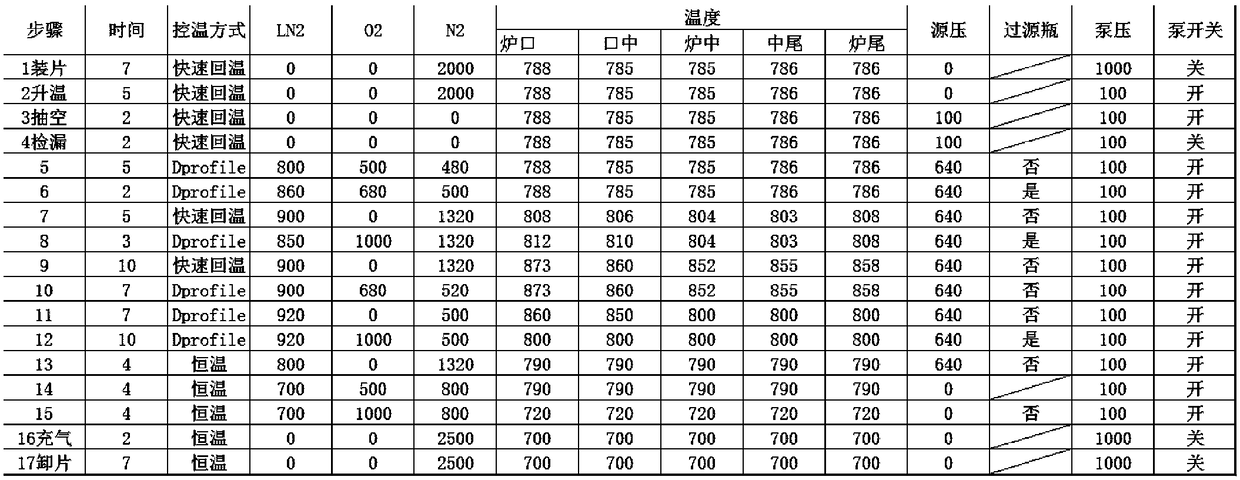

[0040] A diffusion method with high concentration of phosphosilicate glass and high square resistance, such as figure 1 As shown in steps 6-12, specifically:

[0041] For the first pre-deposition, the quartz tube diffusion furnace is stabilized at the preset temperature and the preset nitrogen flow rate, and nitrogen and oxygen carrying phosphorus oxychloride are introduced. The nitrogen flow rate carrying phosphorus oxychloride is 860 sccm, and the oxygen flow rate is 680 sccm. The duration is 2min, the preset nitrogen flow rate is 500sccm, and the preset temperature in the furnace is 783-787°C;

[0042]After the first temperature rise and the first pre-deposition are completed, the nitrogen and oxygen carrying phosphorus oxychloride are stopped in the quartz tube diffusion furnace, and the nitrogen flow is stabilized at the preset nitrogen flow rate, and the furnace tube is heated to the predetermined temperature for 5 minutes. The preset temperature in the furnace is 803-8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com