Chitosan soft capsule, its preparation method and application

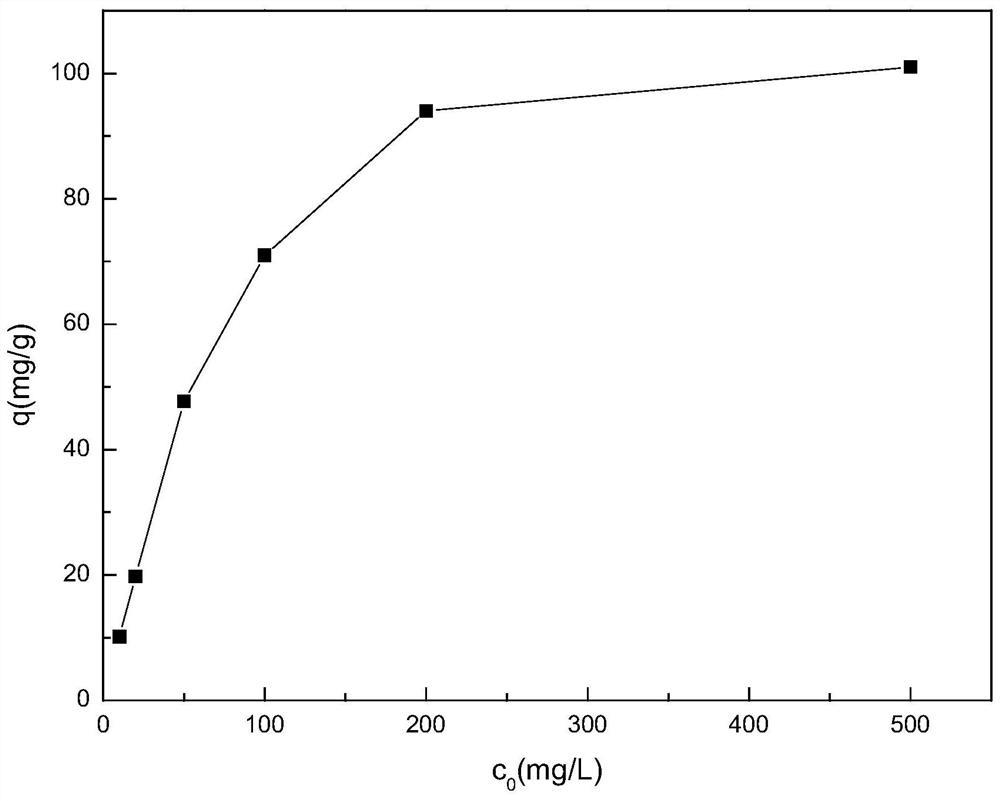

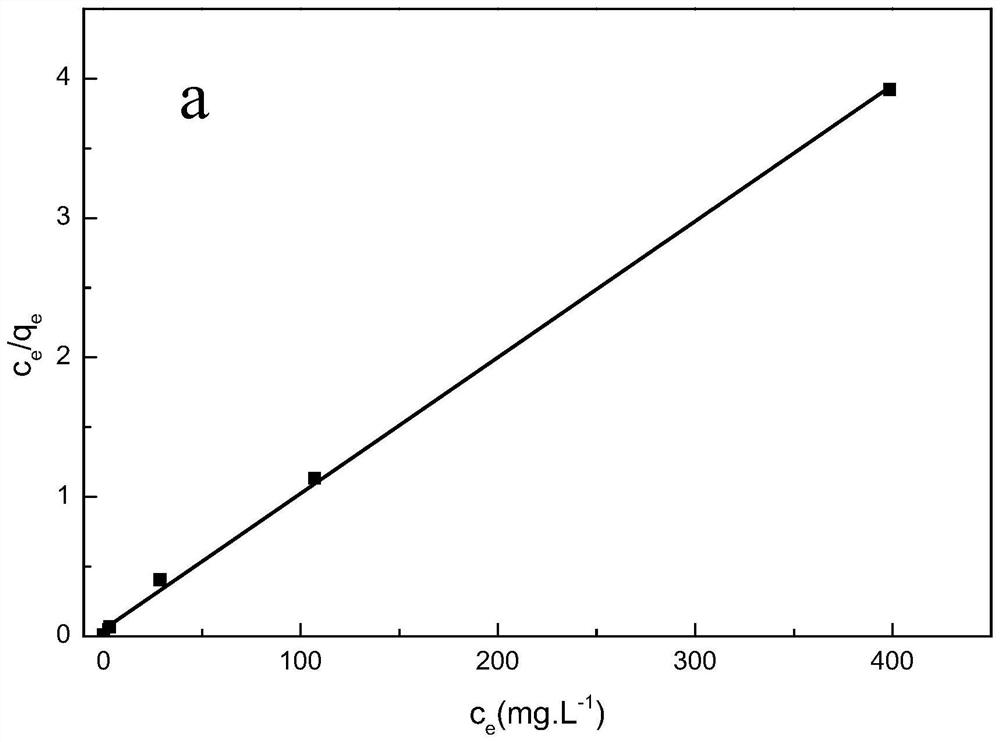

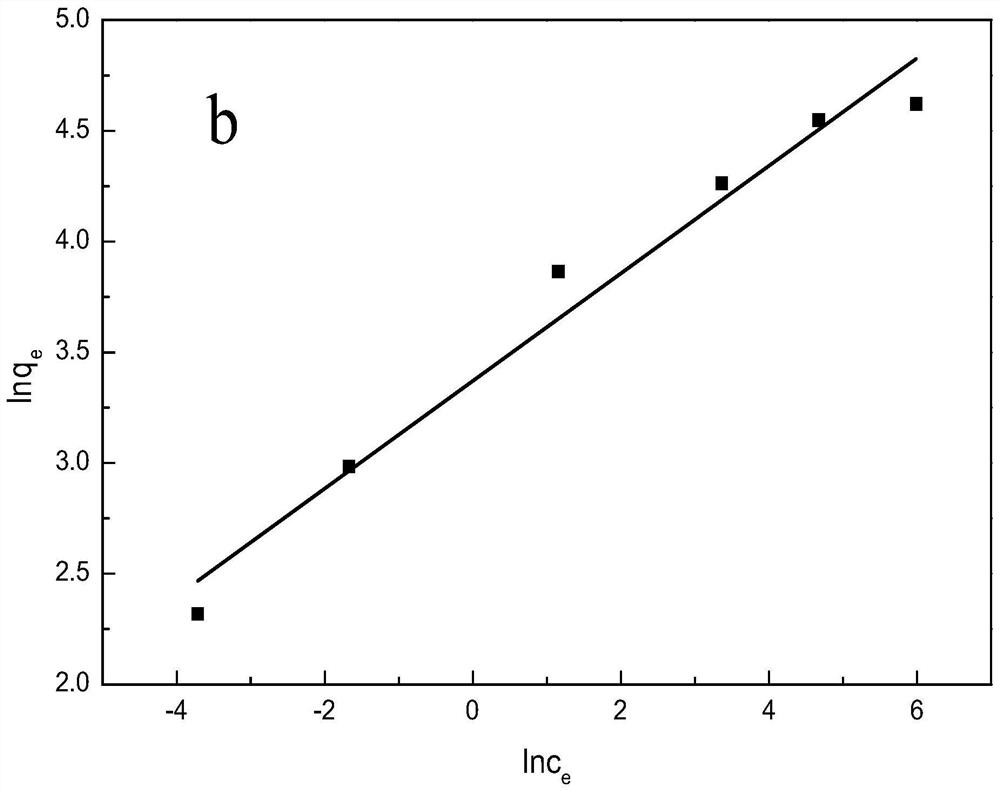

A chitosan gel, chitosan technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as reducing the adsorption capacity of chitosan, and achieve heavy metal ion adsorption. Strong ability, suitable for mass production, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of chitosan soft capsule, it comprises the following steps:

[0032] Mix chitosan and acetic acid aqueous solution evenly to obtain chitosan gel solution; preferably, the volume concentration of acetic acid in the acetic acid aqueous solution is 3-5%; preferably, the amount ratio of chitosan and acetic acid aqueous solution is 3-5g : 80-150ml; Preferably, the chitosan and the acetic acid aqueous solution are mixed uniformly and left to stand overnight; Preferably, the uniform mixing is to stir at 50-120r / min for 30-90min.

[0033] Chitosan gel solution and trihexyl tetradecyl phosphine chloride are mixed and stirred evenly to obtain a reaction solution; preferably, the volume ratio of chitosan gel solution and trihexyl tetradecyl phosphine chloride is 10- 20:1.

[0034] The reaction solution is dripped into the aqueous solution of sodium tripolyphosphate under the condition of stirring, filtered and washed to obtain soft capsules of chitosa...

Embodiment 1

[0040] The embodiment of the present invention provides a kind of preparation method of chitosan soft capsule, it comprises following preparation steps:

[0041] S11. Mix chitosan and acetic acid aqueous solution according to the ratio of 4g: 100ml to obtain chitosan gel solution; wherein, the volume concentration of acetic acid in the acetic acid aqueous solution is 3%;

[0042] S12. Mix 100ml of chitosan gel solution and 10ml of trihexyltetradecylphosphine chloride, and stir at 60r / min for 60min to obtain a reaction solution.

[0043] S13. Drop the reaction liquid into the sodium tripolyphosphate aqueous solution, stir at 500r / min for 30min, filter and wash repeatedly with deionized water several times to obtain the chitosan soft capsule; The mass concentration of sodium phosphate is 5%.

Embodiment 2

[0045] The embodiment of the present invention provides a kind of preparation method of chitosan soft capsule, it comprises following preparation steps:

[0046] S21. Mix chitosan and acetic acid aqueous solution according to the ratio of 5g: 120ml, and let stand overnight to obtain chitosan gel solution; wherein, the volume concentration of acetic acid in the acetic acid aqueous solution is 4%;

[0047] S22. Mix 150ml of chitosan gel solution and 10ml of trihexyltetradecylphosphine chloride, and stir at 80r / min for 50min to obtain a reaction solution.

[0048] S23, drop the reaction liquid into the aqueous solution of sodium tripolyphosphate, stir at 400r / min for 50min, filter, and wash repeatedly with deionized water several times to obtain the chitosan soft capsule; The mass concentration of sodium polyphosphate is 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com