Titanium-silicon-carbon ceramic structure with hydrophobic microstructure and preparation method of titanium-silicon-carbon ceramic structure

A titanium-silicon-carbon, microstructure technology, applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., to achieve the effect of high shape accuracy and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

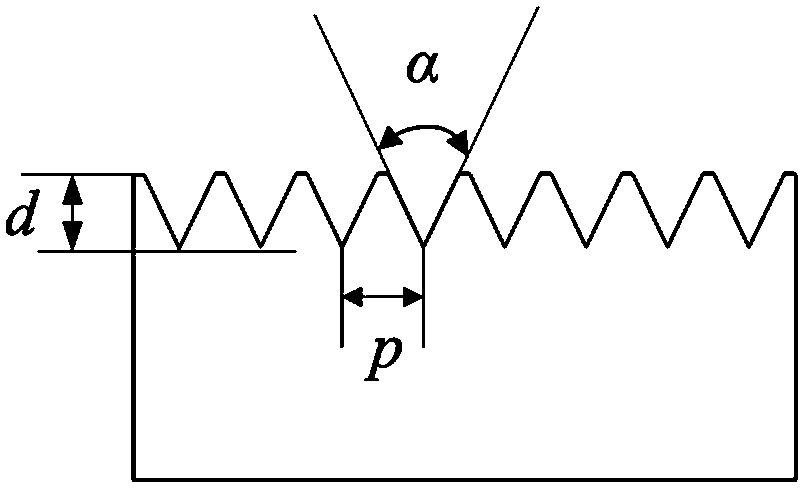

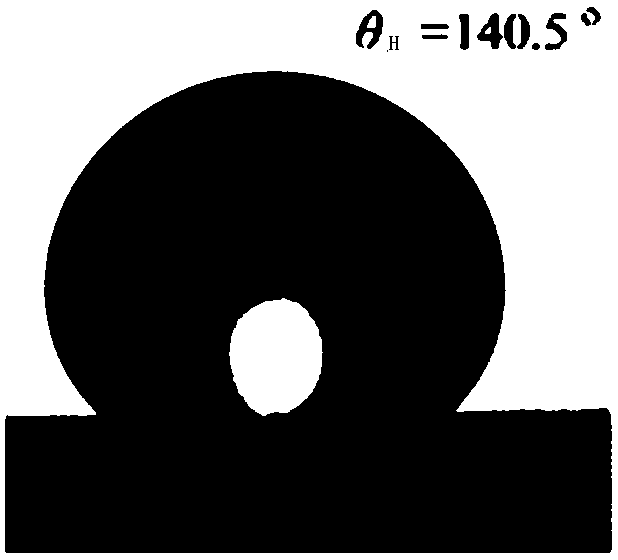

[0028] Such as figure 1 Said, a titanium-silicon-carbon ceramic structure with a hydrophobic microstructure, including a titanium-silicon-carbon ceramic workpiece, the length of the working surface of the titanium-silicon-carbon ceramic workpiece is 15-80 mm, and the width is 5-30 mm. The working surface of the titanium-silicon-carbon ceramic workpiece is uniformly provided with a microgroove array structure composed of several longitudinal microgroove structures parallel to the length direction of the working surface, and the depth of the longitudinal microgroove structure is d 50-200µm, such as depth d Adopt 50µm, 60µm, 80µm, 100µm, 150µm, 200µm, etc.; the pitch of each micro-groove structure p 60~1000µm, such as spacing p Use 120µm, 240µm, 360µm, 480µm, 560µm, 680µm, 720µm, 840µm, 960µm, etc.

[0029] The cross-section of the longitudinal micro-groove structure is V-shaped or rectangular. This embodiment adopts V-shaped, and its included angle a is 60°, of course, other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com